Steel tube centrifugal concrete pipe pile integrality endoscopic detection method

A technology for concrete pipe piles and a detection method, which is applied to measurement devices, infrastructure tests, instruments, etc., can solve the problems of inconvenient on-site operation, incomplete application, and the integrity detection results of dynamic measurement methods need to be verified and corrected. The effect of convenient on-site operation, low cost and simple device structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

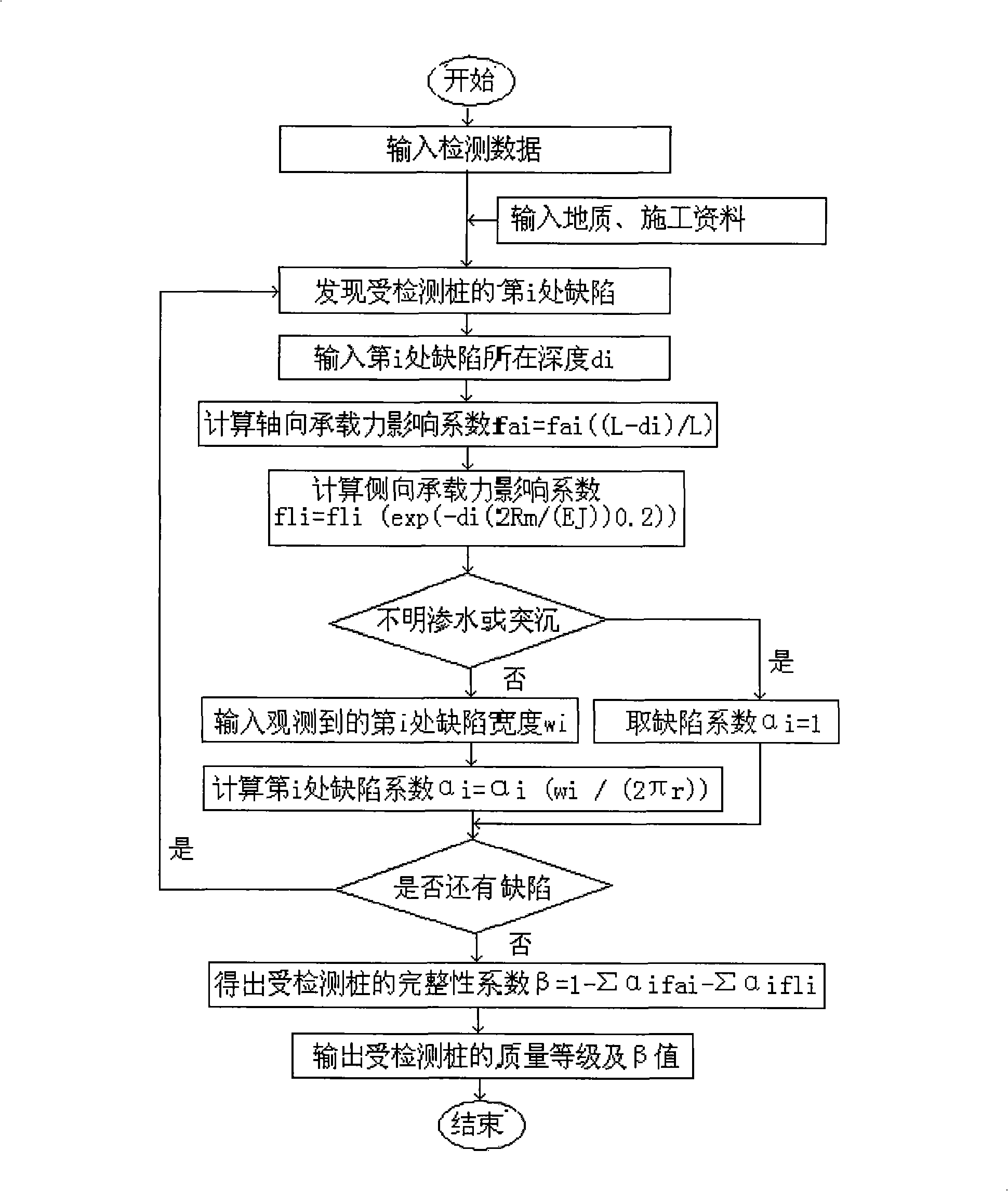

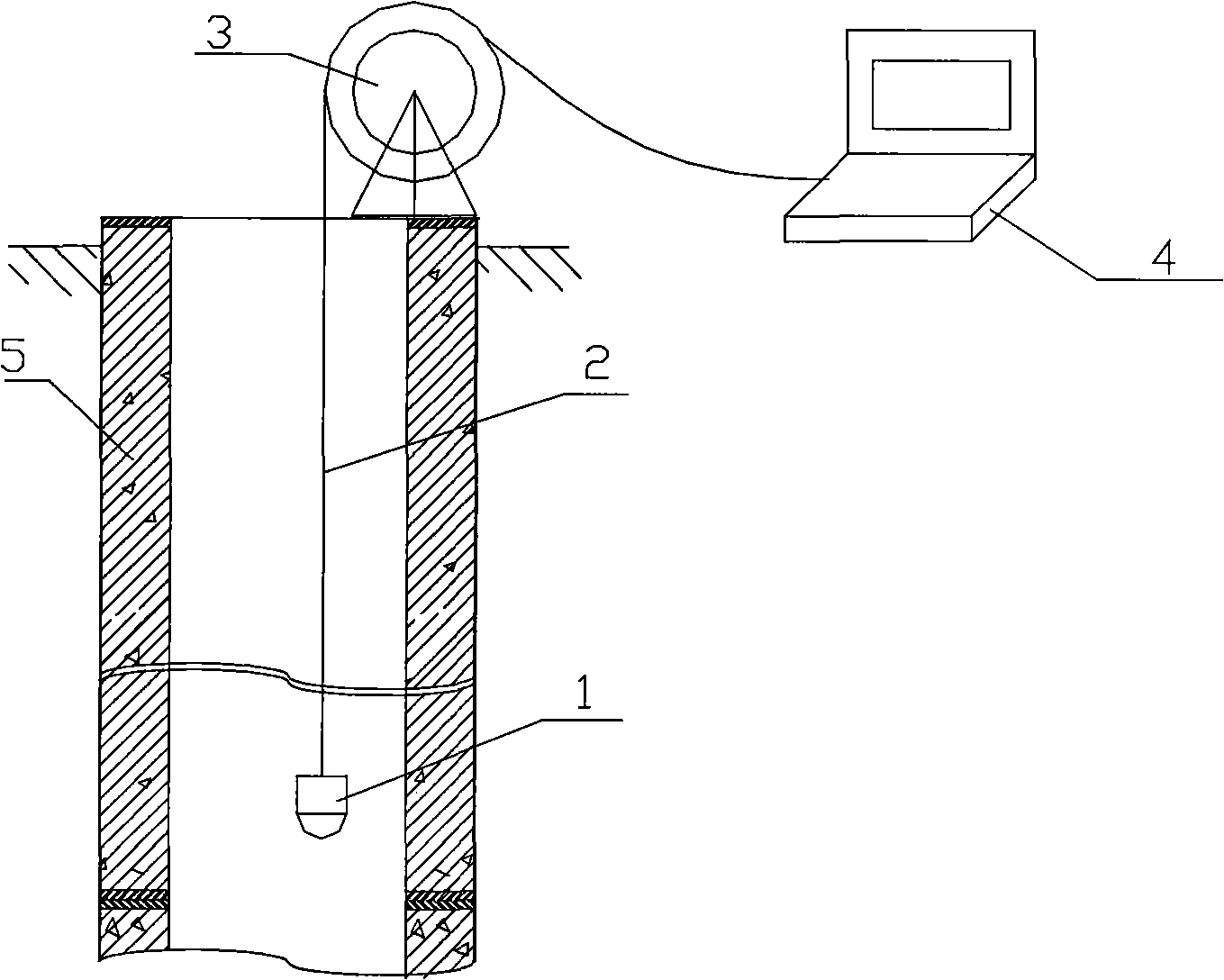

Method used

Image

Examples

Embodiment 1

[0043] Embodiment 1. After the construction of steel pipe centrifugal concrete pipe piles in a construction site, the integrity of the piles was detected by using the endoscopic detection method of the present invention. When a pile with a length of 69m was piling, a sudden change in the hammer penetration was found. It was found that the pile hole was blocked by broken concrete at a depth of 41m and water seepage occurred. The calculated integrity coefficient β=0.6 can be judged as a pile with obvious defects and affecting the structural bearing capacity of the pile, that is, a Class III pile; Comparing the integrity test results of the variation test method, the two are relatively close in finding the nature and depth of cracked concrete defects. The other piles were detected to have normal soil core height (0.9 can be judged as a pile There are slight defects in the body and will not affect the normal performance of the bearing capacity of the pile body structure, that is, ...

Embodiment 2

[0044] Embodiment 2. In the bending test of steel pipe centrifugal concrete pipe pile members, the endoscopic detection method of the present invention provides a kind of observation concrete cracking sequence, crack spacing, crack width and length, and judges whether the concrete reaches the means of failure state.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com