Novel low carbon complex cement

A carbon composite and cement technology, applied in sustainable waste treatment, solid waste management, climate sustainability, etc., to reduce pollution, save production costs, and ensure the pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Raw materials were weighed in proportion: 60 tons of consolidated coal slag, 12 tons of Portland cement clinker, 5 tons of slag, 1 ton of gypsum, 0.4 tons of activator, and 3 tons of quicklime; the formula of the activator is: Na 2 CO 3 0.1 T, sodium sulfate Na 2 SO 4 0.1 ton, sodium hydroxide NaOH 0.1 ton, sodium silicate Na 2 SiO 3 0.1 ton; the raw materials are mixed and ground into powder until the sieve residue of 0.045mm is less than 10%, and the prepared fly ash composite cement reaches the grade standards of 32.5 and 42.5 respectively.

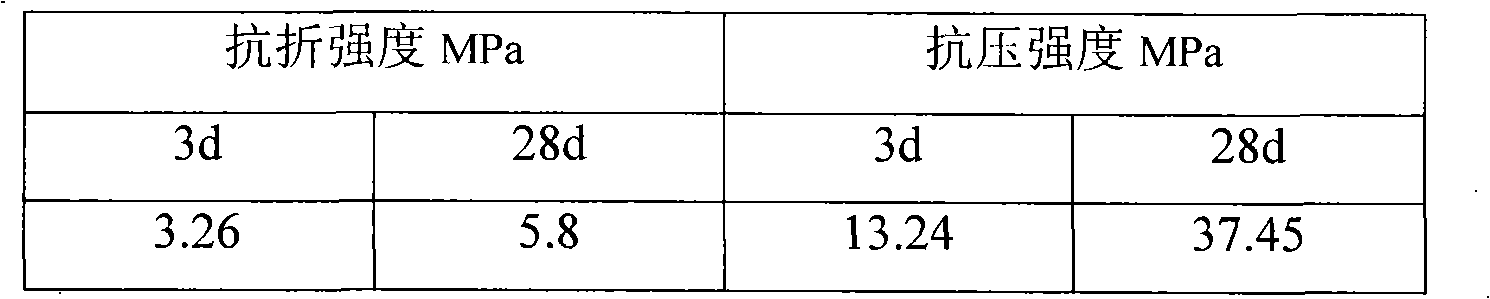

[0031]

Embodiment 2

[0033] Raw materials are weighed in proportion: 65 tons of consolidated coal slag, 15 tons of Portland cement clinker, 10 tons of slag, 1 ton of gypsum, 1 ton of activator, and 3 tons of quicklime; the formula of the activator is: sodium carbonate Na 2 CO 3 0.25 tons, sodium sulfate Na 2 SO 4 0.25 tons, sodium hydroxide NaOH 0.25 tons, sodium silicate Na 2 SiO 3 0.25 tons; the raw materials are mixed and ground into powder until the sieve residue of 0.045mm is less than 10%, and the prepared fly ash composite cement reaches the grade standards of 32.5 and 42.5 respectively.

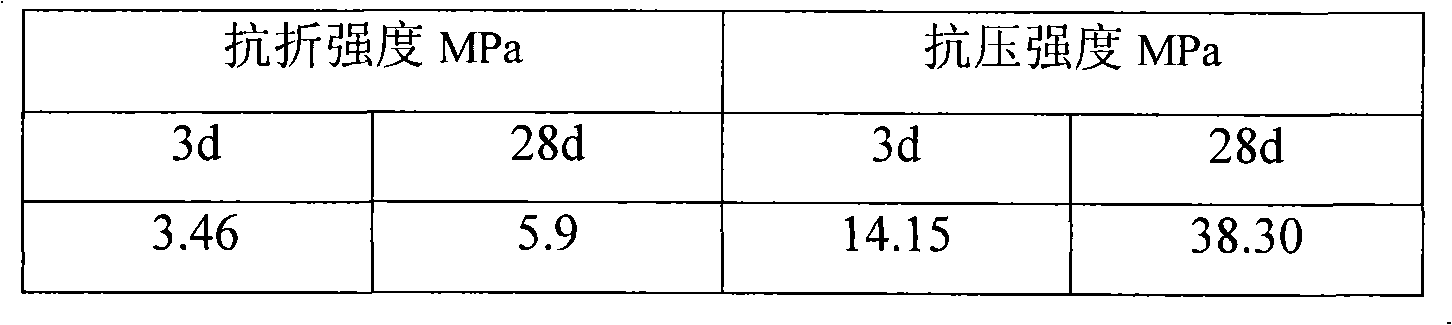

[0034]

Embodiment 3

[0036] Raw materials were weighed in proportion: 63 tons of consolidated coal slag, 14 tons of Portland cement clinker, 10 tons of slag, 2 tons of gypsum, 1 ton of activator, and 5 tons of quicklime; the formula of the activator is: sodium carbonate Na 2 CO 3 0.25 tons, sodium sulfate Na 2 SO4 0.25 tons, sodium hydroxide NaOH 0.25 tons, sodium silicate Na 2 SiO 3 0.25 tons; the raw materials are mixed and ground into powder until the sieve residue of 0.045mm is less than 10%, and the prepared fly ash composite cement reaches the grade standards of 32.5 and 42.5 respectively.

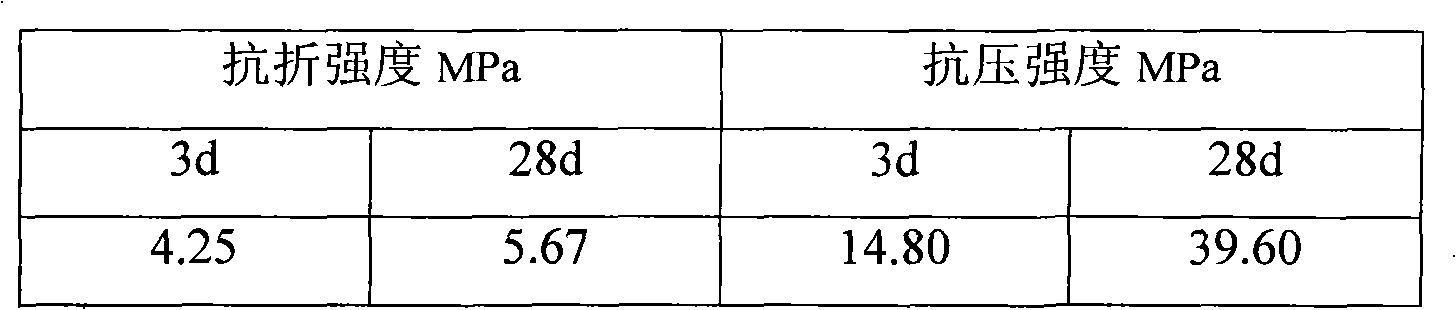

[0037]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com