Method for preparing garlicin from garlic

A technology of allicin and garlic, which is applied in the field of plant active ingredient extraction, can solve the problems of complex allicin process, non-environmental protection of chemical reagents, long cycle, etc., and achieve the effect of improving the acquisition rate and activity, short cycle and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

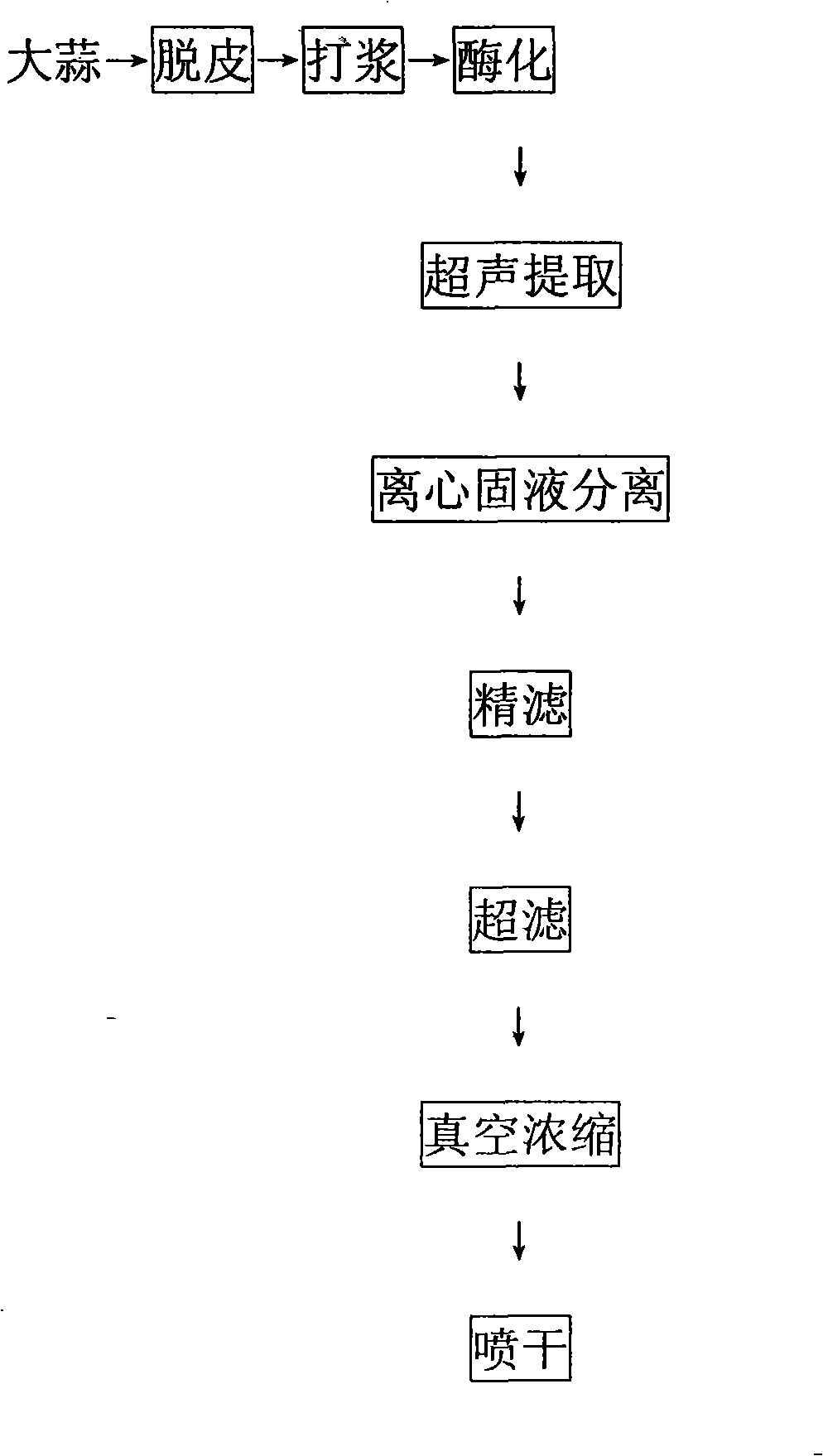

Image

Examples

Embodiment 1

[0020] The method for preparing allicin from garlic of the present invention consists of the following steps:

[0021] a. After the garlic is peeled, crush and beat;

[0022] b. Enzymatic conversion: convert alliin to allicin, the solvent is an aqueous solution of ethanol, the concentration of which is 25%, and the weight ratio of garlic pulp and solvent is 1:5, input into the reaction kettle, and keep warm at 45°C for 100min;

[0023] c. Ultrasonic extraction: Add the above-mentioned solvent to the material after enzymatic conversion, so that the weight ratio of garlic pulp and solvent is adjusted to 1:8, and input into the ultrasonic extraction unit, the ultrasonic frequency is 25KHz, and it is treated at room temperature for 30 minutes;

[0024] d. Impurity removal: After centrifugal solid-liquid separation and precision filtration, perform ultrafiltration, and use ultrafiltration membrane to separate and remove macromolecular substances. The ultrafiltration membrane is an ...

Embodiment 2

[0028] The method for preparing allicin from garlic of the present invention consists of the following steps:

[0029] a. After the garlic is peeled, crush and beat;

[0030] b. Enzymatic conversion: convert alliin to allicin, the solvent is water, and the weight ratio of garlic pulp and solvent is 1:2, and input it into the reaction kettle, and keep it warm at 30°C for 120min;

[0031] c. Ultrasonic extraction: Add the above-mentioned solvent to the material after enzymatic conversion, so that the weight ratio of garlic pulp and solvent is adjusted to 1:6, input the ultrasonic extraction unit, the ultrasonic frequency is 25KHz, and treat at room temperature for 60 minutes;

[0032] d. Impurity removal: After centrifugal solid-liquid separation and precision filtration, perform ultrafiltration, and use ultrafiltration membrane to separate and remove macromolecular substances. The ultrafiltration membrane is an inorganic membrane, and the ultrafiltration membrane has a cut-off ...

Embodiment 3

[0036] The method for preparing allicin from garlic of the present invention consists of the following steps:

[0037] a. After the garlic is peeled, crush and beat;

[0038] b. Enzymatic conversion: convert alliin to allicin, the solvent is an aqueous solution of ethanol, its concentration is 50%, the weight ratio of garlic pulp and solvent is 1:6, and input into the reaction kettle, and keep warm at 50°C for 60min;

[0039] c. Ultrasonic extraction: Add the above-mentioned solvent to the material after enzymatic conversion, so that the weight ratio of garlic pulp and solvent is adjusted to 1:10, and input it into the ultrasonic extraction unit, the ultrasonic frequency is 25KHz, and it is treated at room temperature for 45 minutes;

[0040] d. Impurity removal: After centrifugal solid-liquid separation and precision filtration, perform ultrafiltration, and use ultrafiltration membrane to separate and remove macromolecular substances. The ultrafiltration membrane is a ceramic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com