MgO-Cr2O3 paint

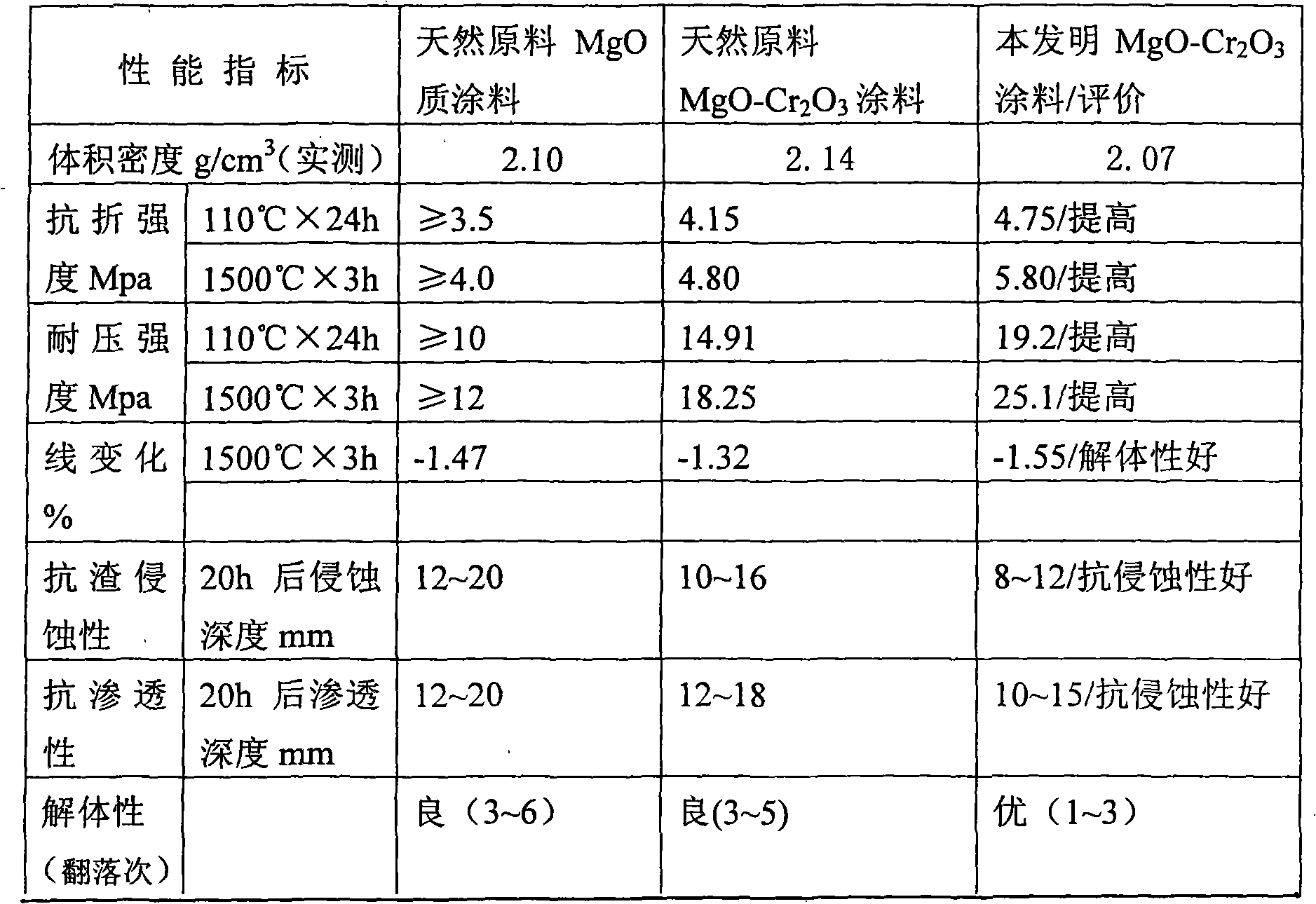

A coating and raw material technology, applied in the direction of coating, casting molding equipment, casting mold, etc., can solve the problem of low density, linear shrinkage, strength, slag corrosion resistance, low penetration resistance, difficult to meet the requirements of long-term continuous casting, increase Problems such as the difficulty of coating renewal operation, to achieve the effect of excellent corrosion resistance, natural mineral resources saving, and good plasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Embodiment 1: the magnesia-chrome brick (bulk density >= 3.0g / cm2) that reclaims with steelworks 3 , MgO≥80%, CaO≤1.4%, SiO 2 ≤1.5%, Cr 2 o 3 ≥8%), after removing the surface slag, they are processed into two kinds of particles of 3-1mm and 1-0mm respectively, as the aggregate of the coating composition, and the fine powder part adopts natural MgO fine powder (index: MgO≥95, CaO≤1.5 , 280 mesh).

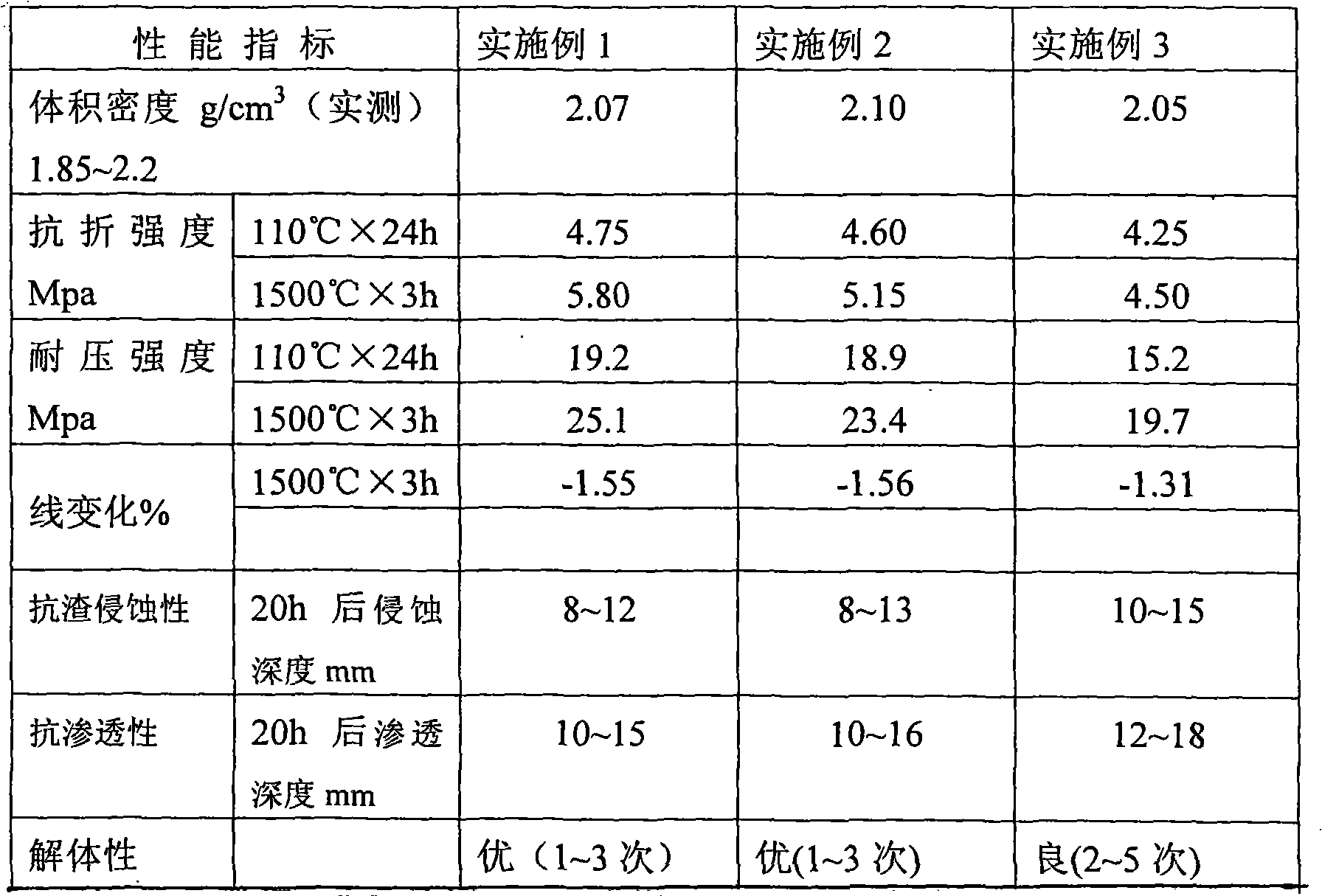

[0016] Coating composition (wt%): 3-1mm particles 40%, 1-0mm particles 26%, magnesia fine powder 22.5%, bonded clay 3%, polyphosphate 3%, borate 1.5%, polychloride 2% , 2% paper fiber, plus 0.5% explosion-proof agent. The coating performance index is shown in Table 2.

Embodiment 2

[0017] Embodiment 2: the magnesia-chrome brick (bulk density ≥ 2.9g / cm2) that cement factory reclaims 3 , MgO≥80%, CaO≤1.5%, SiO 2 ≤1.5%, Cr 2 o 3 ≥6%), after removing the surface slag, they are processed into two kinds of particles of 3-1mm and 1-0mm respectively, as the aggregate of the coating composition, and the fine powder part adopts natural MgO fine powder (index: MgO≥95, CaO≤ 1.5, 280 mesh).

[0018] Coating composition (wt%): same as embodiment 1, coating performance index is shown in Table 2.

Embodiment 3

[0019]Embodiment 3: the magnesia-chrome brick (bulk density >= 2.9g / cm3, MgO >= 80%, CaO >= 1.5%, SiO ≤ 1.5%) that cement plant or steelworks reclaim 2 ≤1.5%, Cr 2 o 3 ≥6%), which are processed into two kinds of particles of 3-1mm and 1-0mm, respectively, as the aggregate of the coating composition, and the fine powder part is also fine powder processed from recycled magnesia-chrome bricks (MgO≥80%, Cr 2 o 3 ≥6%, CaO≤1.5, 280 mesh)

[0020] Coating composition (wt%): same as embodiment 1, coating performance index is shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bulk density | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com