A method for preparing plastic filler using gasification slag as raw material

A technology for gasification slag and coal gasification slag, applied in chemical instruments and methods, solid separation, grain processing, etc. The effect of improving the effect and crushing efficiency, saving natural mineral resources, and shortening the process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

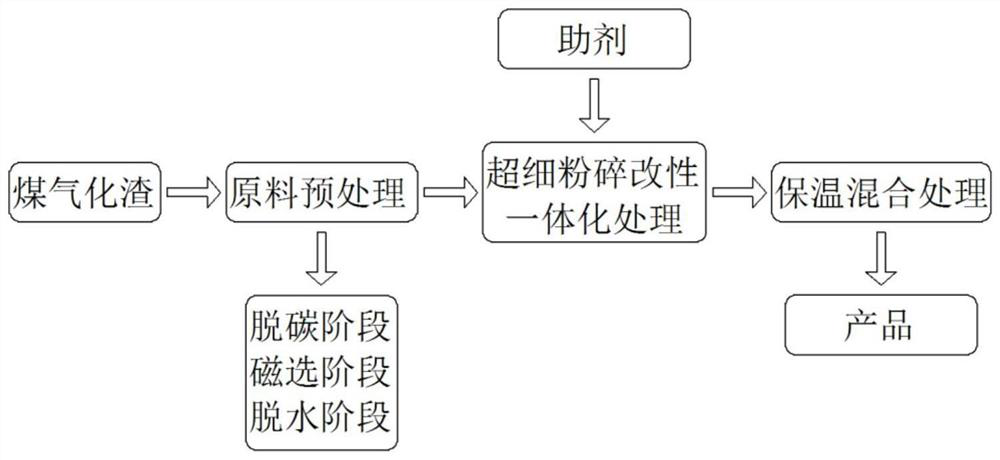

[0039] see figure 1 , a method for preparing plastic filler with gasification slag as raw material, has the following steps:

[0040] (1) Raw material pretreatment

[0041] The coal gasification slag is directly treated or the coal gasification slag is prepared into a slurry for treatment. The raw material pretreatment process includes a decarbonization stage, a magnetic separation stage and a dehydration stage; the decarbonization is determined according to the actual carbon content in the coal gasification slag. Whether the carbonization stage is carried out or not, the decarburization stage is to use the flotation process or the gravity separation process to remove the carbon part of the coal gasification slag. When the carbon content in the coal gasification slag raw material is greater than 5%, the oil absorption value of the subsequent products will be too large. , affecting the processing performance of the subsequent products, it is necessary to decarbonize the coal g...

Embodiment 2

[0047] combine figure 1 Embodiment 1 is further described and explained in detail, and the decarbonization stage, magnetic separation stage, and dehydration stage are freely adjusted and combined according to the content of each component in the coal gasification slag to realize the raw material pretreatment process;

[0048] When the flotation process is adopted in the decarburization stage, kerosene or light diesel oil is used as a collector, sec-octanol or No. 2 oil is used as a foaming agent, and water circulation is used for flotation; the amount of the foaming agent is coal gasification. 0.005-0.1% of the total slag, and the amount of the collector is 0.02-0.5% of the total coal gasification slag;

[0049] In the magnetic separation stage, various heavy metals such as iron oxide, titanium oxide, manganese oxide and chromium oxide in the coal gasification slag are removed, and the magnetic field intensity of the magnetic separator in the magnetic separation stage is adjus...

Embodiment 3

[0056] In the coal gasification slag produced by a company's production process, the residual carbon content is 15.3%, the iron oxide content is 3.6%, the manganese oxide is not detected, and the moisture content is 4%. Flash drying, magnetic separation for iron removal.

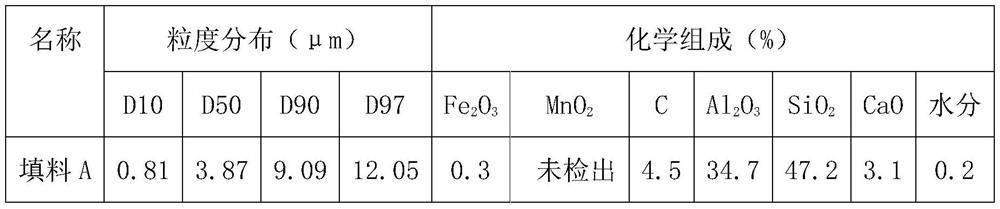

[0057] First, the coal gasification slag was made into a slurry with a concentration of 30%, with 0.1% kerosene as the collector and 0.05% sec-octanol as the detonator, and flotation for 3 times; Magnetic separation under high strength for 1 time; dewater the slurry with a filter press to a water content of 15% after concentrating the slurry; use flash drying equipment to dry the coal gasification slag after flotation under the conditions of an inlet temperature of 200 °C and an outlet temperature of 100 °C ; Then, the dried material is fed into the steam kinetic energy mill with a screw feeder, using superheated steam of 0.7MPa and 290°C, the speed of the classifier is 1500rpm, the slag discharge port is fu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com