Desorption technique for methylbenzene in tail gas from benzyl chloride preparation

A technology of benzyl chloride and toluene, which is applied in the field of toluene desorption process in the tail gas of benzyl chloride production, can solve the problems of affecting the quality of hydrochloric acid products, increasing product consumption and product cost, and toluene cannot be recycled, so as to reduce emissions and reduce product Cost, the effect of improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

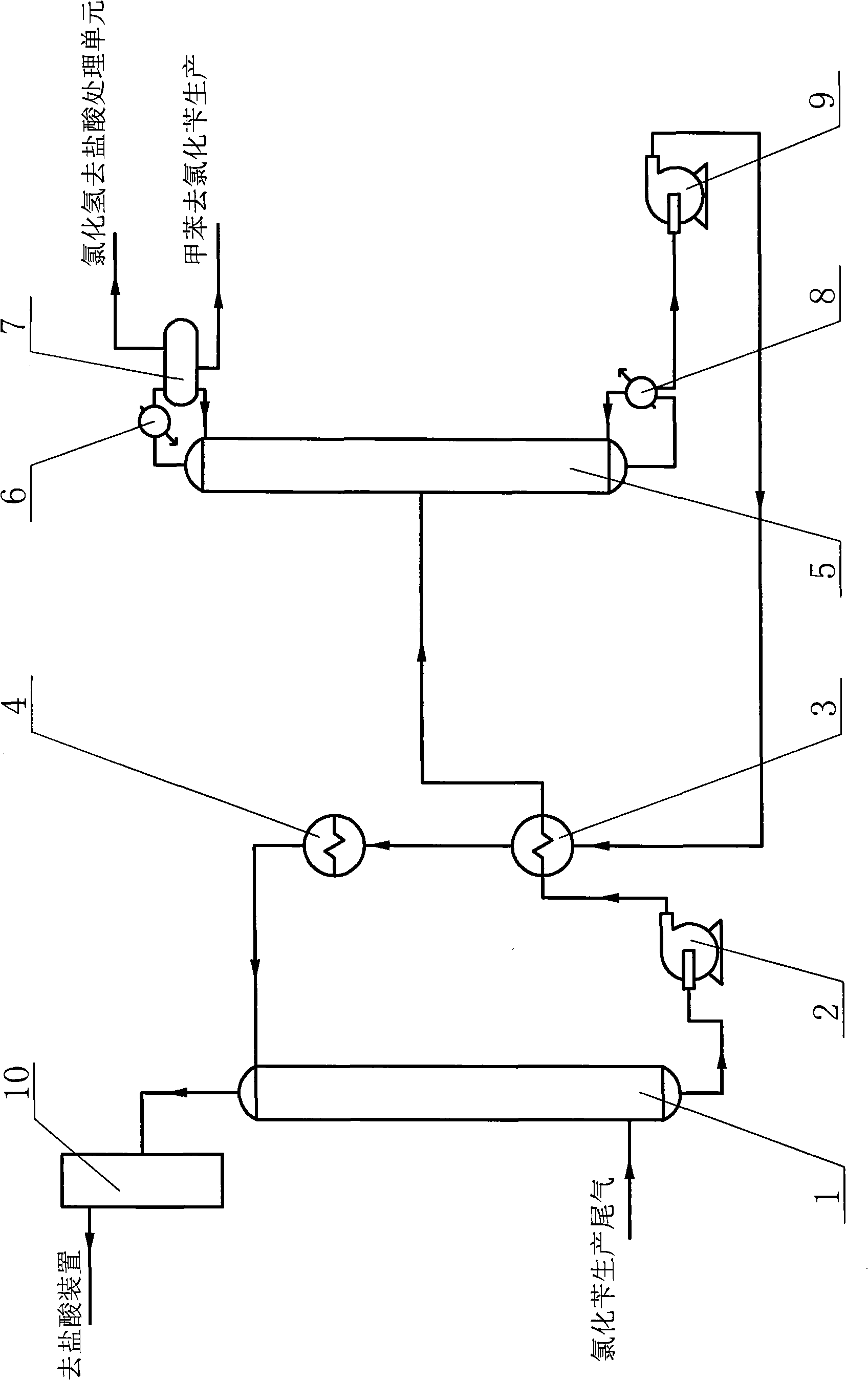

[0016] The desorption process of the present invention is connected with the tail gas device in the benzyl chloride production process, the toluene separated and recovered through the process of the present invention is directly used in the production of benzyl chloride, and the hydrogen chloride tail gas after the absorption tower 1 is sprayed and absorbed enters Absorption in the falling film absorber 10 further reduces the toluene content in the hydrogen chloride tail gas. The device and connection used in the technological process of the present invention are: the bottom of the absorption tower 1 is connected with the pump 2 at the bottom of the absorption tower through a pipeline, the pump 2 at the bottom of the absorption tower 1 is connected with the preheater 3 through a pipeline, and the feed of the preheater 3 The branch is connected to the desorption tower 5 through a pipeline, and the top of the desorption tower 5 is connected to the condenser 6 through a pipeline, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com