Healthy inner wall paint without VOC and preparing method

A kind of interior wall paint, healthy technology, applied in the direction of latex paint, etc., can solve environmental pollution and other problems, and achieve the effect of good opening performance and strong covering rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

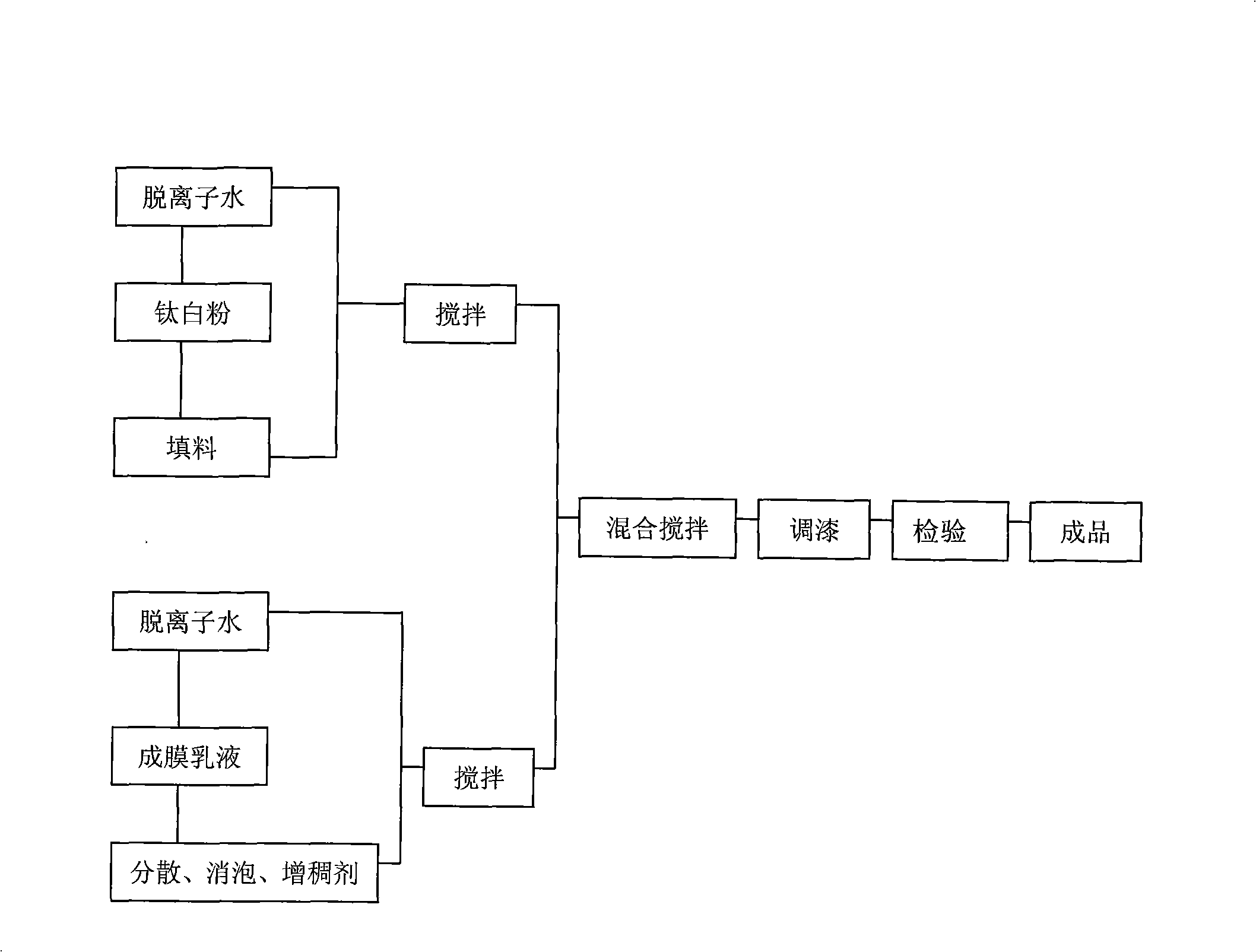

[0024] Referring to the attached picture, every ton of zero-VOC healthy interior wall paint is prepared from the following raw materials: 150kg of deionized water, 200kg of titanium dioxide, 250kg of vinyl acetate-acrylic acid copolymer emulsion, 200kg of superfine calcium carbonate, and 150kg of superfine talcum powder , dispersant 15kg, leveling agent 3kg, thickener 5kg, antifungal agent 2kg, film forming agent 17kg, defoamer 8kg.

[0025] The preparation method of the zero-VOC healthy interior wall paint consists of the following three steps:

[0026] 1. Preparation of slurry

[0027] Weigh 200kg of titanium dioxide, 200kg of superfine calcium carbonate, and 150kg of superfine talcum powder, add 100kg of deionized water and stir evenly, and make 650kg of slurry for subsequent use;

[0028] 2. Preparation of base material

[0029] Weigh 250kg of vinyl acetate-acrylic acid copolymer emulsion and 15kg of dispersant, add remaining 50kg of deionized water, stir to obtain 315kg...

Embodiment 2

[0033] Referring to the attached picture, every ton of zero-VOC healthy interior wall paint is prepared from the following raw materials: 120kg of deionized water, 210kg of titanium dioxide, 260kg of vinyl acetate-acrylic acid copolymer emulsion, 210kg of superfine calcium carbonate, and 150kg of superfine talcum powder , Dispersant 12kg, leveling agent 6kg, thickener 4kg, antifungal agent 3kg, film forming agent 15kg, defoamer 10kg.

[0034] 1. Preparation of slurry

[0035] Take by weighing 210kg of titanium dioxide, 210kg of superfine calcium carbonate, and 150kg of superfine talcum powder, add 80kg of deionized water and stir evenly, and make 650kg of slurry for subsequent use;

[0036] 2. Preparation of base material

[0037] Take by weighing 260kg of vinyl acetate-acrylic acid copolymer emulsion and 12kg of dispersant, add remaining 40kg of deionized water, stir to obtain 312kg of base material;

[0038] 3. Preparation of coating

[0039] Mix the 650kg slurry prepared...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com