System for low temperature plasma pre-oxidizing NOx of auxiliary NH3-SCR fine purification diesel engine

A NH3-SCR, low-temperature plasma technology, applied in mechanical equipment, engine components, combustion engines, etc., can solve the problems of difficult and reliable rapid SCR process, poor catalytic conversion effect of NOx, poisoning of pre-oxidation catalysts, etc., and achieve inhibition of sulfuric acid. Salt generation, avoidance of physical failure, low energy consumption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific implementation of the present invention will be further described below in conjunction with the accompanying drawings.

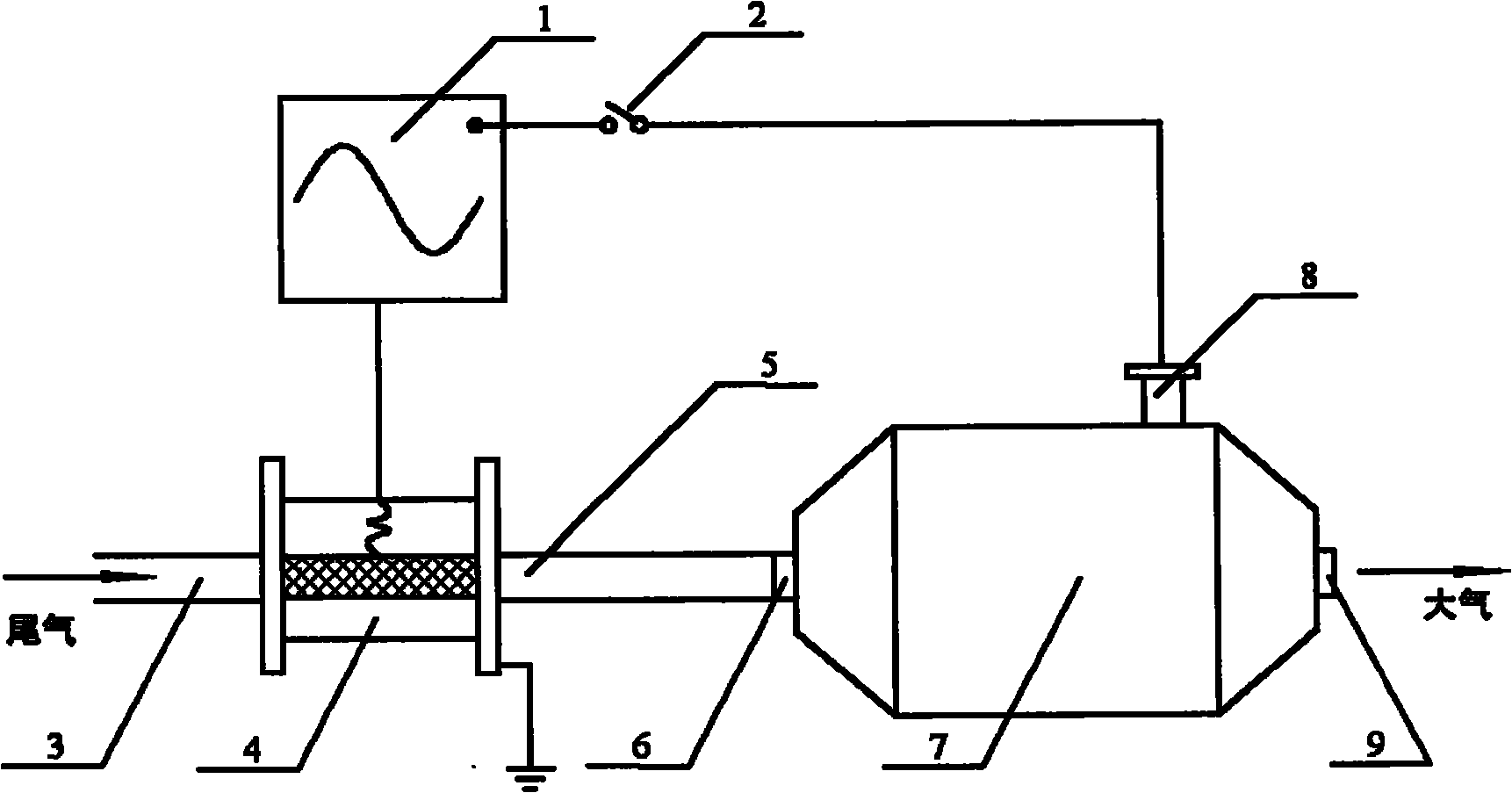

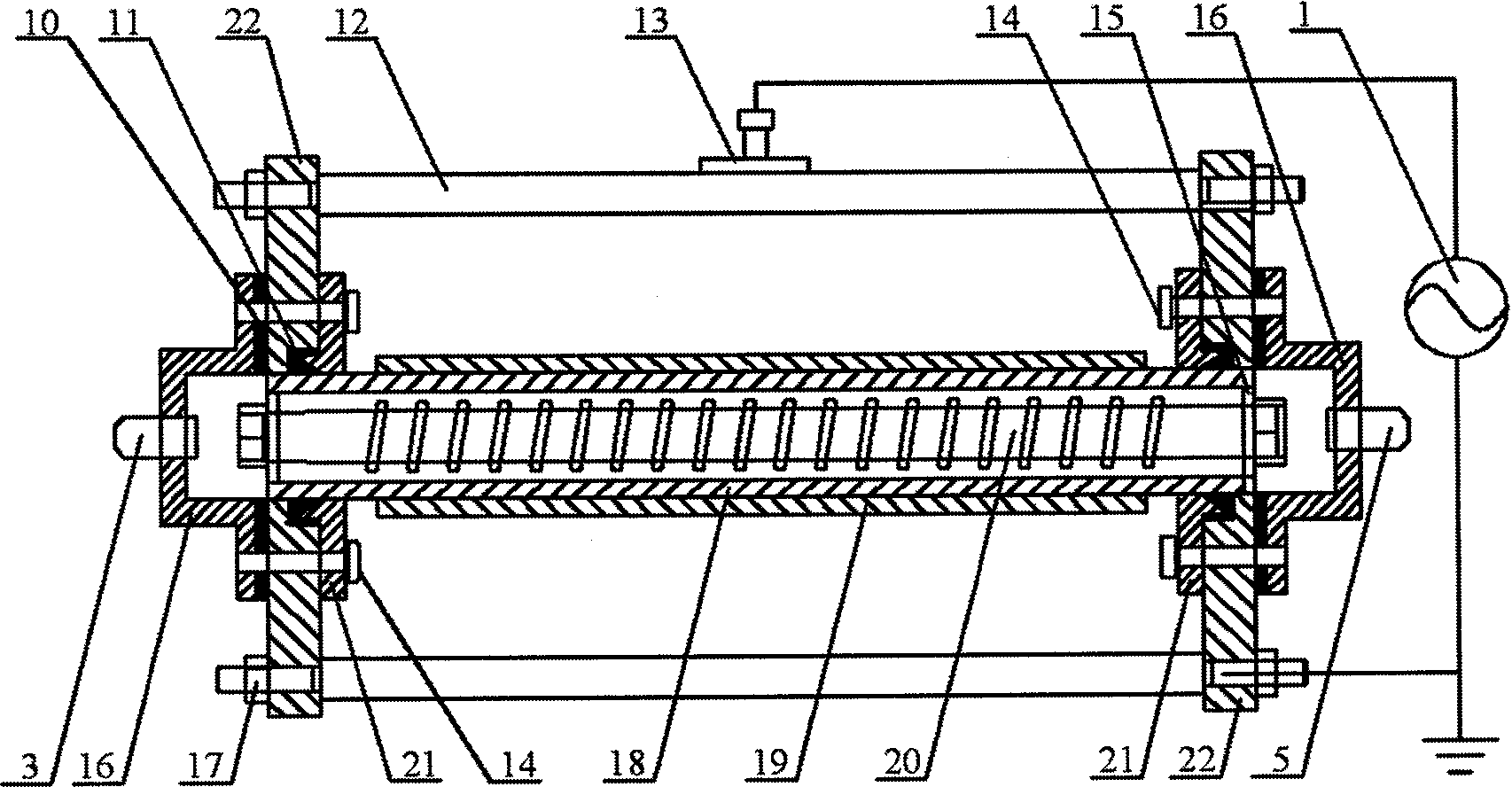

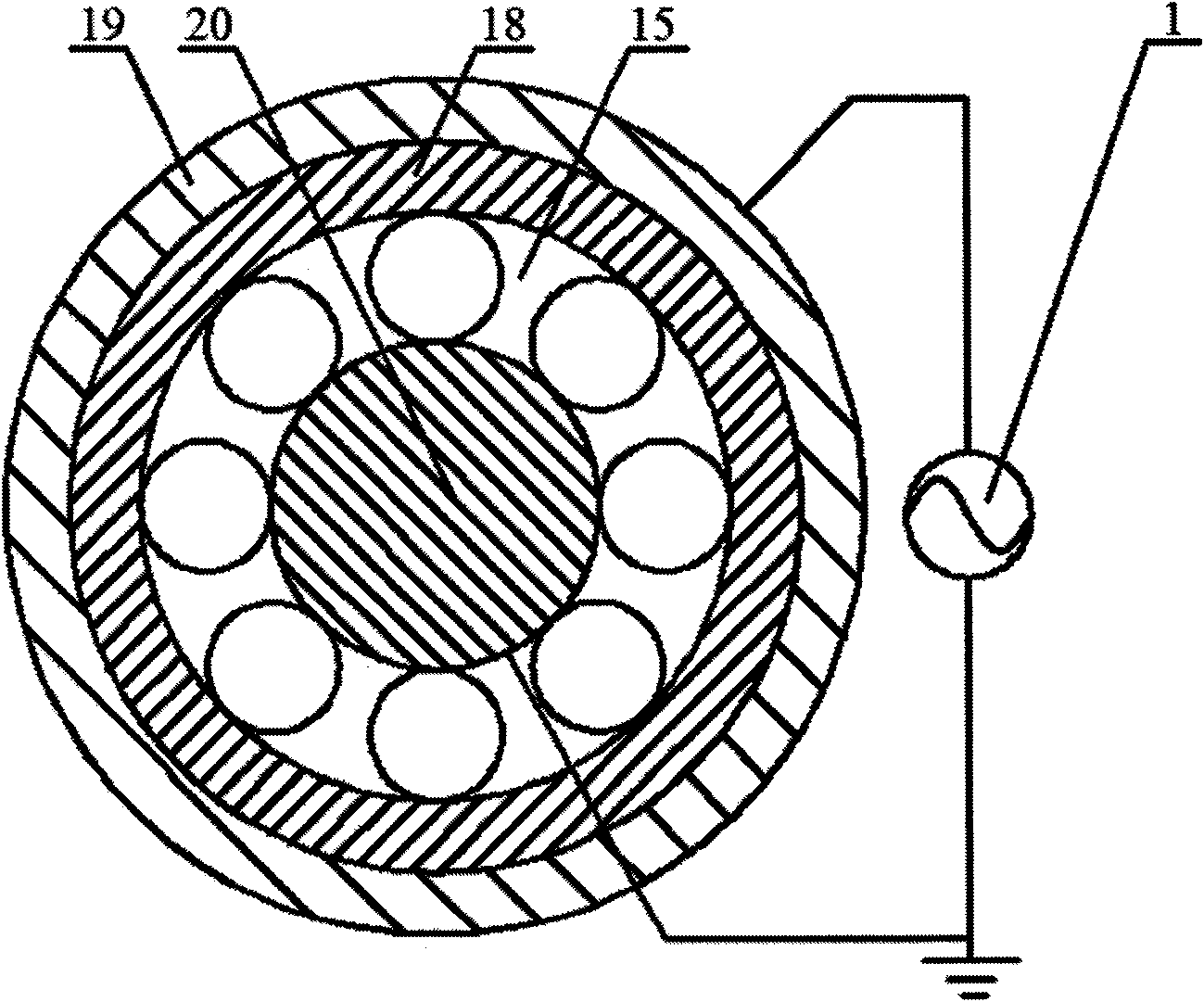

[0022] Such as figure 1 , figure 2 , image 3 As shown, the present invention includes: a high-voltage high-frequency pulse power supply 1, a power control switch 2, a DBD reactor 4, an SCR reactor 7, and a temperature sensor 8. The DBD reactor 4 is a coaxial dielectric barrier discharge reactor. The reactor consists of wall plate aluminum 22, aluminum rods, stainless steel core rod low-voltage electrode 20, outer sealing ring 10, inner sealing ring 11, high-voltage terminal 13, floating centering porous plate 15, outer sealing flange 16, corundum tube 18, Stainless steel mesh high voltage electrode 19, bracket bolt 17, inner sealing flange 21, sealing flange bolt 14, air inlet pipe 3, air outlet pipe 5. Among them, two wall panel aluminum 22 and 4 aluminum rods are connected by bracket bolts 17 to form an aluminum rod bracket 12. The wall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com