Control device for hybrid vehicle power transmitting apparatus

一种动力传递装置、混合动力车辆的技术,应用在混合动力车辆、通用动力装置的多个不同原动机的布置、动力装置等方向,能够解决加速燃料消耗等问题,达到促进暖机、改进燃料消耗、实现燃料消耗的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

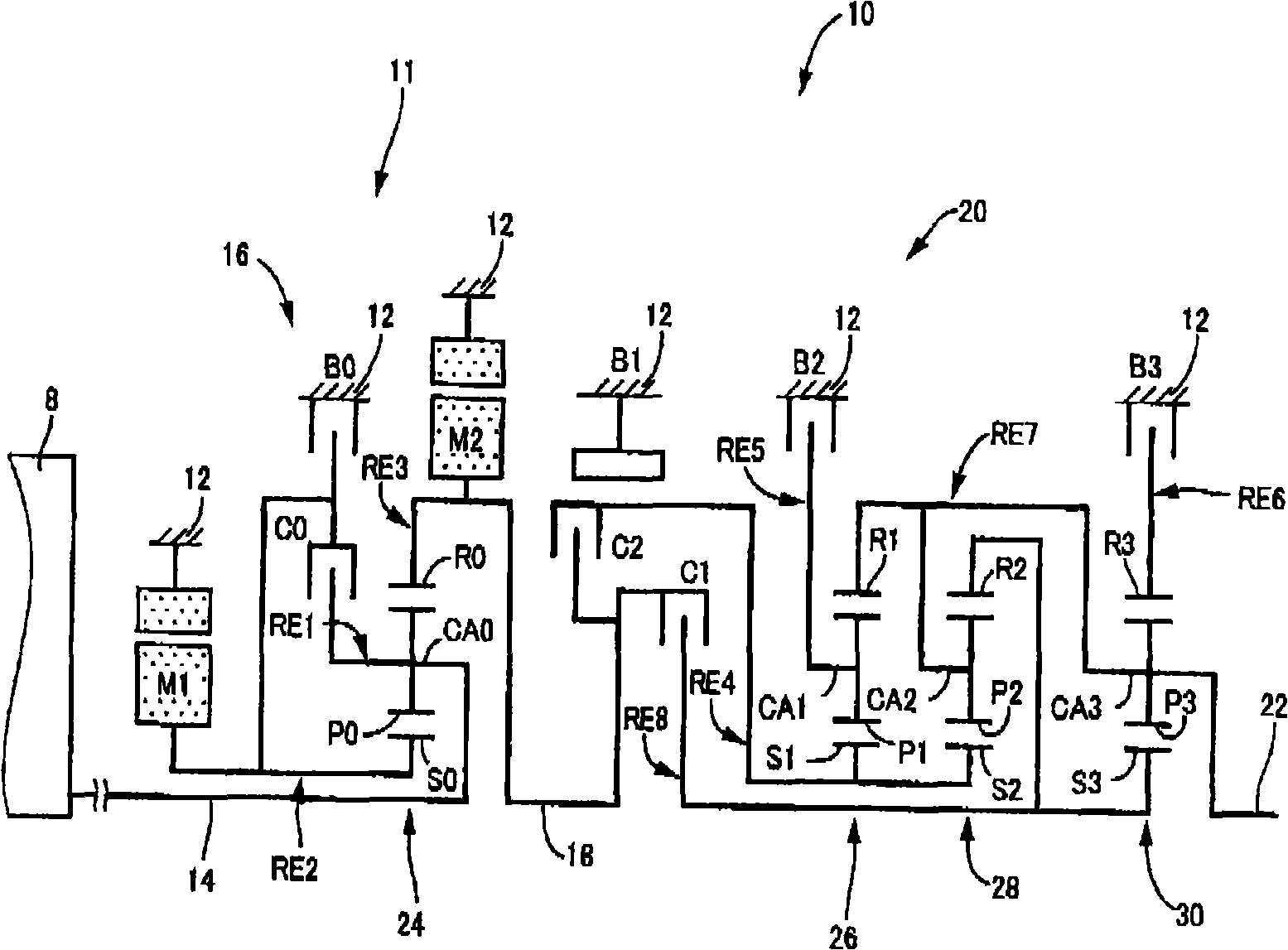

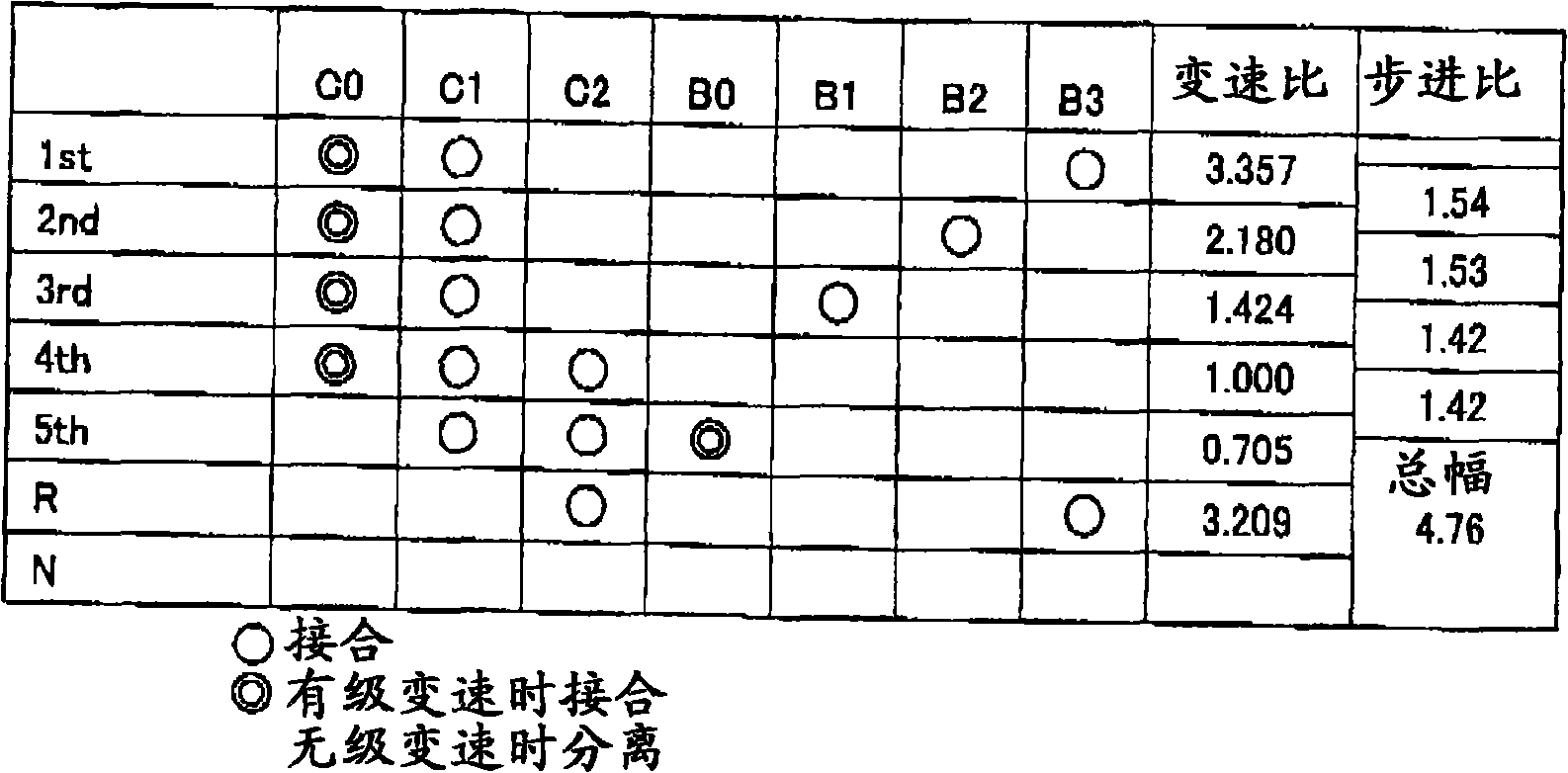

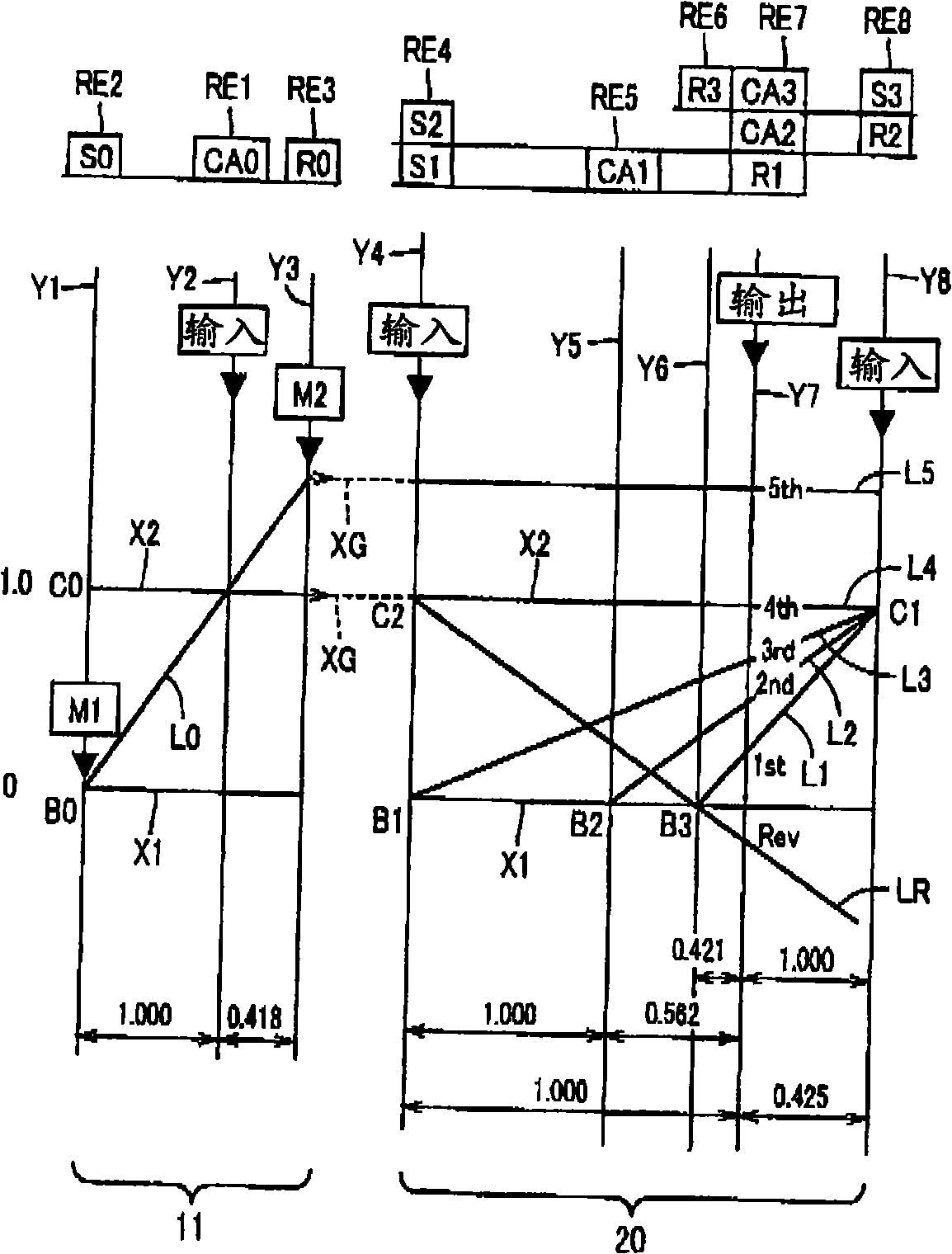

[0049] figure 1 is a schematic diagram showing a transmission mechanism 10 forming a part of a hybrid vehicle power transmission device to which a control device according to an embodiment of the present invention is applied. like figure 1 As shown in , the transmission mechanism 10 includes: an input shaft 14 serving as an input rotating member; a differential portion directly connected to the input shaft 14 or indirectly connected to the input shaft 14 through a pulse absorbing damper (vibration damper) not shown. 11. The automatic transmission part 20, which passes through the differential mechanism 11 and the driving wheels 38 via the power transmission member (power transmission shaft) 18 (see Figure 6 ) is connected in series to serve as a stepped transmission; and an output shaft 22 connected to the automatic transmission portion 20 as an output rotary member. All of these components are arranged in a transmission case 12 (hereinafter simply referred to as "case 12")...

no. 2 example

[0170] In the second embodiment, the transmission mechanism 10 of the first embodiment is composed of Figure 12 The shifting mechanism 210 is shown instead. Figure 12 is a schematic diagram showing a transmission mechanism 210 forming a part of a hybrid vehicle power transmission device to which the present invention is applied, except that the switching clutch C0 and the switching brake B0 are omitted, which basically corresponds to figure 1 The structure of the first embodiment is shown.

[0171] like Figure 12 As shown, the transmission mechanism 210 includes: an input shaft 14 serving as an input rotary member coaxially arranged in a transmission housing (hereinafter simply referred to as “housing 12”) mounted on a vehicle body and serving as a non-rotating member; to the input shaft 14 or indirectly connected to the input shaft 14 via a pulse absorbing damper (vibration damping device) (not shown), a differential portion 211 serving as a continuously variable transmi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com