Tough mannich base curing agent and preparation thereof

A Mannich base and curing agent technology, applied in the field of curing agent, can solve the problems of difficult source of raw materials, insufficient flexibility, unsatisfactory water resistance and seawater resistance, etc., achieve good development prospects, improve adhesion and adhesion Relay effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

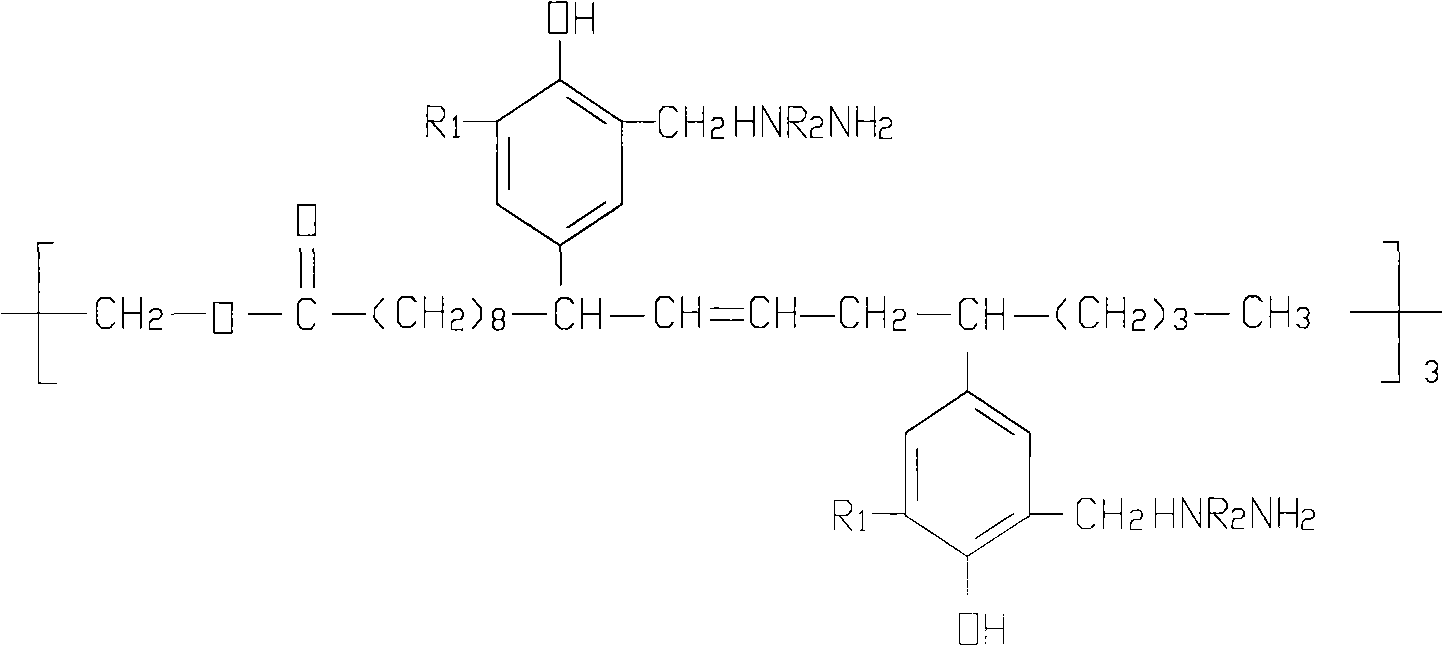

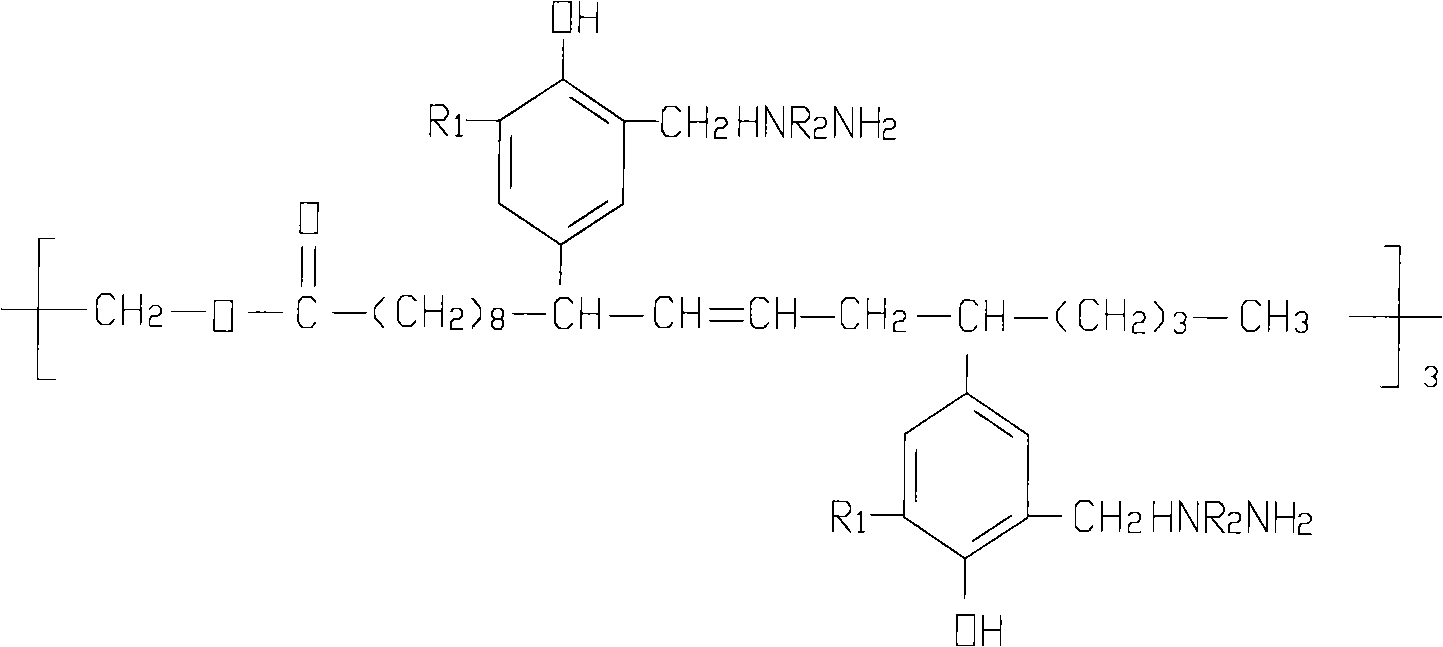

Method used

Image

Examples

Embodiment 1

[0040] Embodiment 1 (small test synthetic example)

[0041] Add 200g of nonylphenol, 120g of tung oil, and 1.0g of p-toluenesulfonic acid to a 2000ml four-neck flask equipped with a stirrer, electric heating mantle, dropping device, condenser and thermometer, and control the system temperature at 95°C to maintain the reaction 1.0h. The temperature of the system was controlled at 50°C, and 180 g of ethylenediamine was added dropwise for 1.5 hours. After the dropwise addition is completed, the temperature of the system is controlled at 50° C., and 380 g of formaldehyde is started to be added dropwise for 1.5 hours. Heat the material, control the temperature at 100°C, and react for 2.0 hours. The system was heated up and dehydrated under normal pressure and reduced pressure. Cool the material, that is, add 30g of ethanol, stir evenly, and obtain the finished product.

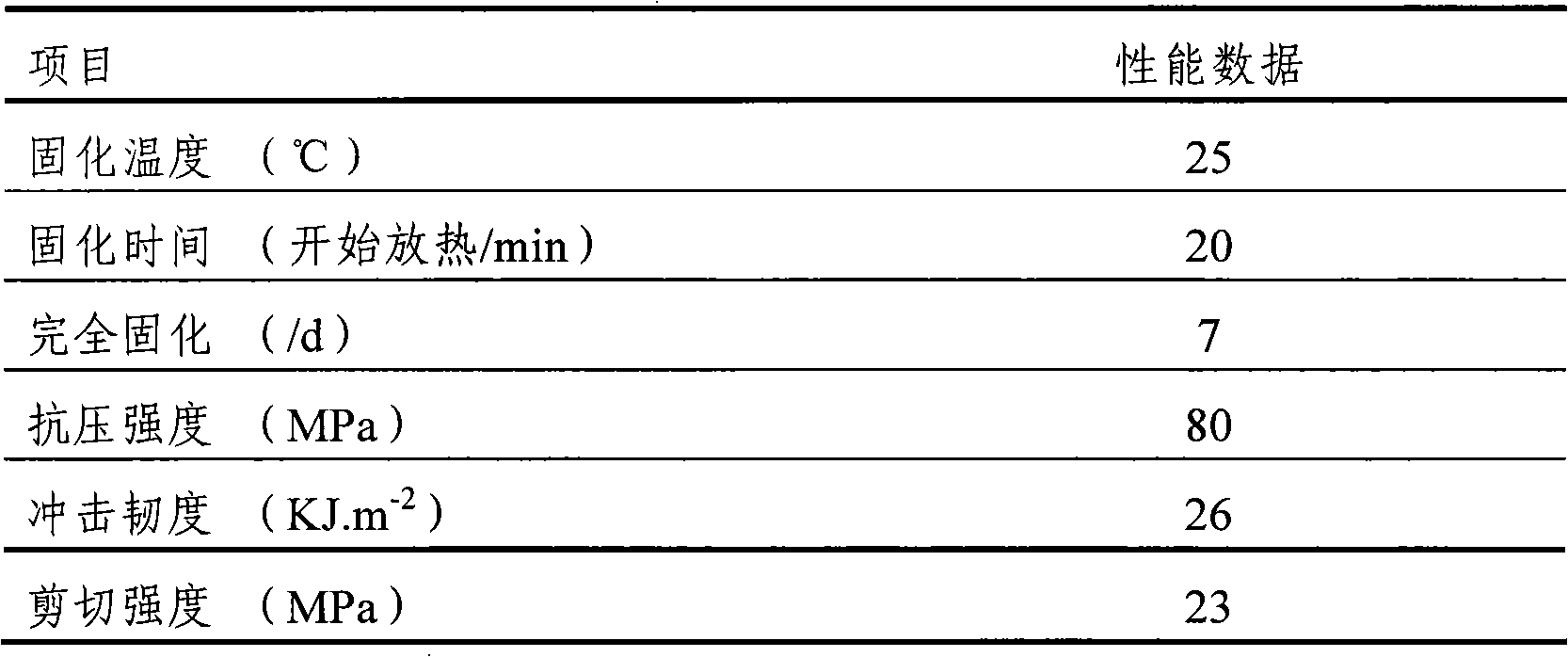

[0042]The technical indicators of the finished product are: amine value (mgKOH / g): 500; viscosity (25°C, mPa...

Embodiment 2

[0049] Add 200g of phenol, 120g of tung oil, and 1.0g of p-toluenesulfonic acid to a 2000ml four-neck flask equipped with a stirrer, electric heating mantle, dropping device, condenser and thermometer. Control the system temperature at 95°C and maintain the reaction for 1.0h . The temperature of the system was controlled at 50°C, and 180 g of ethylenediamine was added dropwise for 1.5 hours. After the dropwise addition is completed, the temperature of the system is controlled at 50° C., and 380 g of formaldehyde is started to be added dropwise for 1.5 hours. Heat the material, control the temperature at 100°C, and react for 2.0 hours. The system was heated up and dehydrated under normal pressure and reduced pressure. Cool the material, that is, add 30g of ethanol, stir evenly, and obtain the finished product.

[0050] The technical indicators of the finished product are: amine value (mgKOH / g): 490; viscosity (25°C, mPa.s): 1600; appearance: reddish-brown transparent viscous...

Embodiment 3

[0052] Add 200g of nonylphenol, 120g of tung oil, and 1.0g of p-toluenesulfonic acid to a 2000ml four-neck flask equipped with a stirrer, electric heating mantle, dropping device, condenser and thermometer, and control the system temperature at 95°C to maintain the reaction 1.0h. The temperature of the system was controlled at 50°C, and 180 g of ethylenediamine was added dropwise for 1.5 hours. After the dropwise addition is completed, the temperature of the system is controlled at 50° C., and 380 g of formaldehyde is started to be added dropwise for 1.5 hours. Heat the material, control the temperature at 100°C, and react for 2.0 hours. The system was heated up and dehydrated under normal pressure and reduced pressure. Cool the material, that is, add 30g of benzyl alcohol, stir evenly, and obtain the finished product.

[0053] The technical indicators of the finished product are: amine value (mgKOH / g): 510; viscosity (25°C, mPa.s): 1450; appearance: reddish-brown transpare...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Amine value | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Amine value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com