Preparation of alkali lignin-phenolic composite adhesive for timber industry

A technology for composite adhesives and wood adhesives, applied in the direction of aldehyde/ketone condensation polymer adhesives, adhesives, adhesive types, etc. Abundant, cheap raw materials, and the effect of reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] The first step: preparation of hydroxymethylated alkali lignin:

[0020] 1): Add 40g of formaldehyde solution, 110g of the first batch of alkali lignin, and 170g of water into a 500ml four-neck flask, adjust the pH to 11 with lye, heat up to 85°C, and react for 80min.

[0021] 2): Add 73g of the second batch of alkali lignin, and add a certain amount of lye to ensure that its pH value is the same as that of step 1, and react at 85°C for 70min.

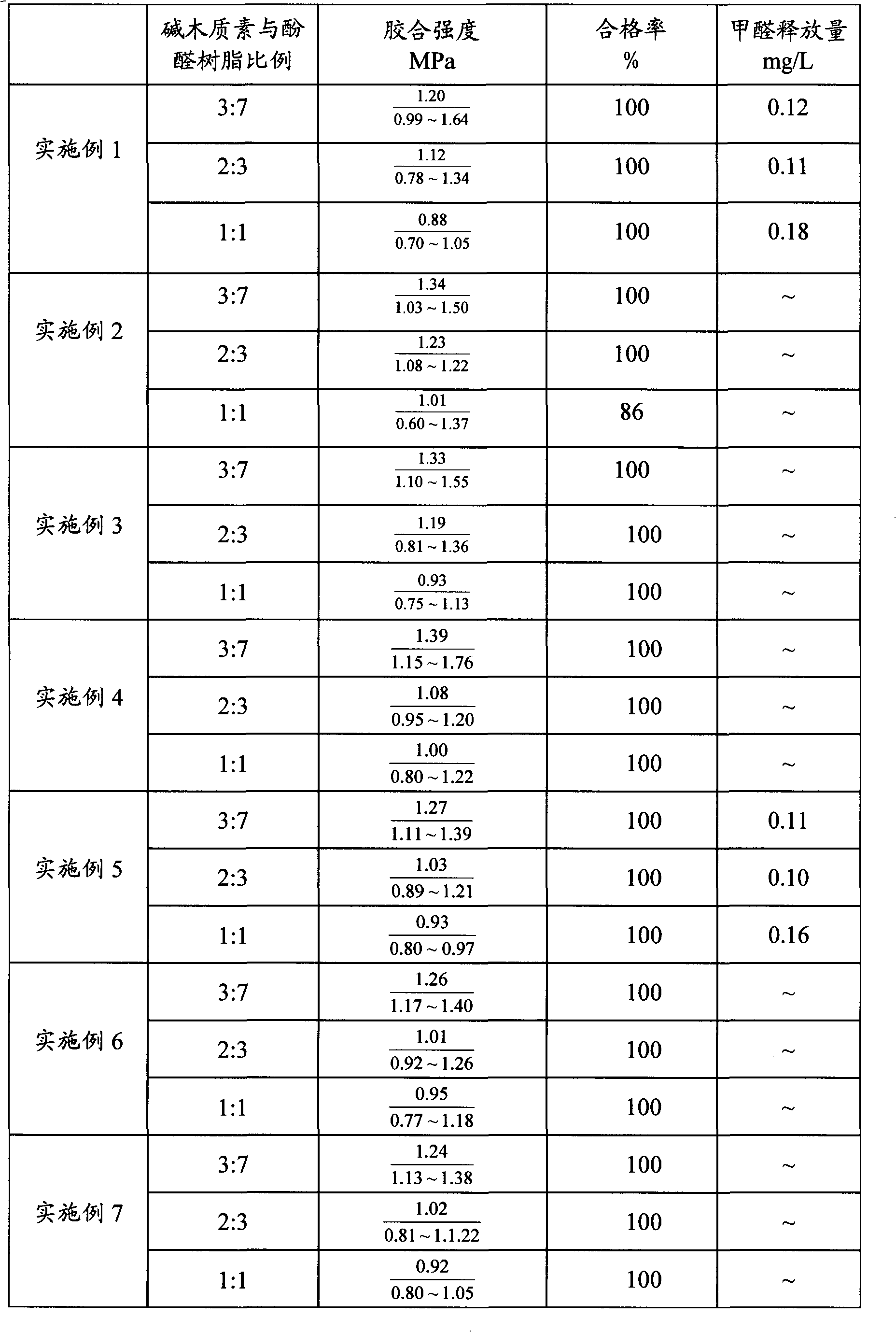

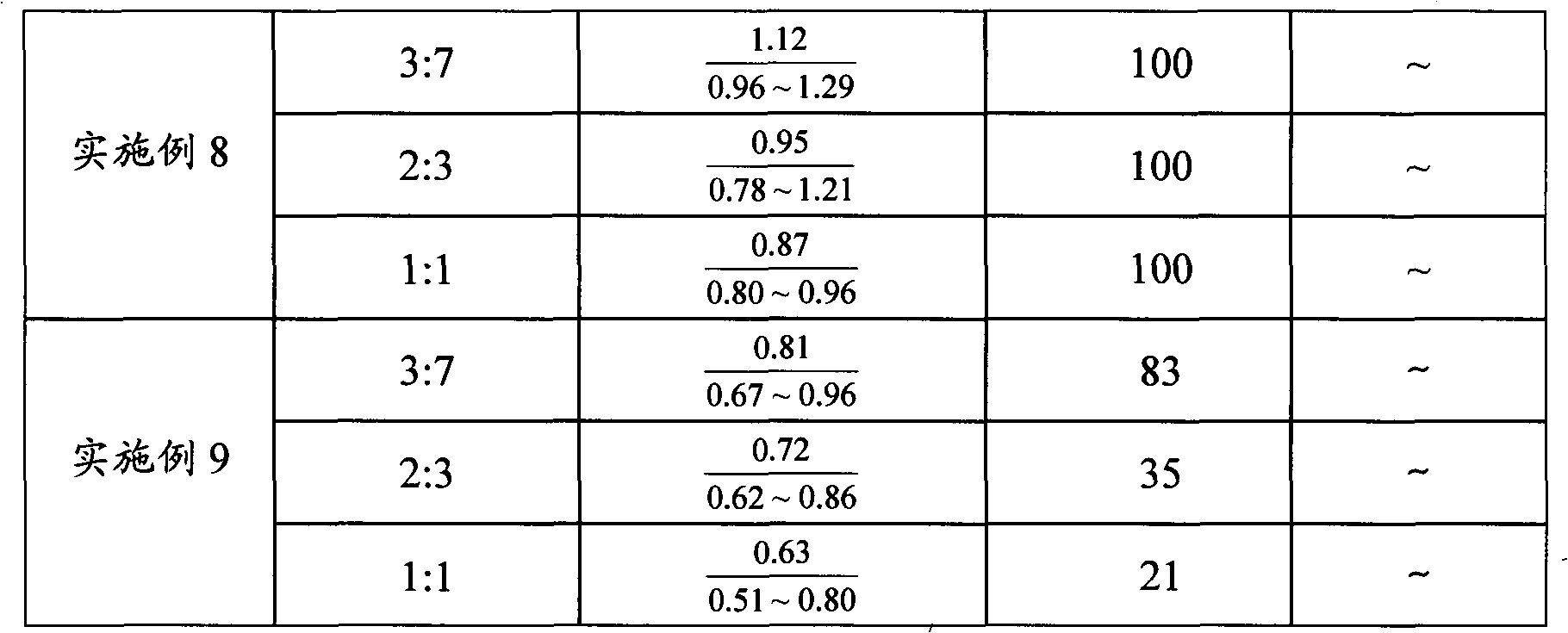

[0022] 3): Add 37g of the third batch of alkali lignin, and add a certain amount of lye to make the pH value the same as step 1, and react at 85°C for 60min. Cool the discharge. Test their performance respectively, and the results are listed in attached table 2.

[0023] The second step: the preparation of alkali lignin-phenolic resin composite adhesive:

[0024] At room temperature, mix the hydroxymethylated alkali lignin prepared in the first step with the resole phenolic resin according to 3:7, 2:3, 1:1 (mass ratio) Stir ...

Embodiment 2

[0026] The first step: preparation of hydroxymethylated alkali lignin:

[0027] 1): Add 40g of formaldehyde solution, 110g of the first batch of alkali lignin, and 170g of water into a 500ml four-necked flask, adjust the pH value to 12 with lye, raise the temperature to 80°C, and react for 70min.

[0028] 2): Add 73g of the second batch of alkali lignin, and add a certain amount of lye to ensure that its pH value is the same as that of step 1, and react at 80°C for 60min.

[0029] 3): Add 37g of the third batch of alkali lignin, and add a certain amount of lye to make the pH value the same as step 1, and react at 80°C for 50min. Cool the discharge. Test their performance respectively, and the results are listed in attached table 2.

[0030] The second step: the preparation of alkali lignin-phenolic resin composite adhesive:

[0031] At room temperature, mix the hydroxymethylated alkali lignin prepared in the first step with the resole phenolic resin according to 3:7, 2:3, 1...

Embodiment 3

[0033] The first step: preparation of hydroxymethylated alkali lignin:

[0034]1): Add 40g of formaldehyde solution, 110g of the first batch of alkali lignin, and 170g of water into a 500ml four-neck flask, adjust the pH value to 13 with lye, raise the temperature to 80°C, and react for 70min.

[0035] 2): Add 73g of the second batch of alkali lignin, and add a certain amount of lye to ensure that its pH value is the same as that of step 1, and react at 80°C for 60min.

[0036] 3): Add 37g of the third batch of alkali lignin, and add a certain amount of lye to make the pH value the same as step 1, and react at 80°C for 50min. Cool the discharge. Test their performance respectively, and the results are listed in attached table 2.

[0037] The second step: the preparation of alkali lignin-phenolic resin composite adhesive:

[0038] At room temperature, mix the hydroxymethylated alkali lignin prepared in the first step with the resole phenolic resin according to 3:7, 2:3, 1:1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com