Preparation of alkali lignin-phenolic composite adhesive for timber industry

A technology of composite adhesives and wood adhesives, applied in the direction of aldehyde/ketone condensation polymer adhesives, adhesives, adhesive types, etc., can solve the problems of few types of alkali lignin, limited application range, and limited uses, etc., and achieve raw material Inexpensive, abundant sources, large steric hindrance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] The first step: preparation of hydroxymethylated alkali lignin:

[0020] 1): Add 40g of formaldehyde solution, 110g of the first batch of alkali lignin, and 170g of water into a 500ml four-neck flask, adjust the pH to 11 with lye, heat up to 85°C, and react for 80min.

[0021] 2): Add 73g of the second batch of alkali lignin, and add a certain amount of lye to ensure that its pH value is the same as that of step 1, and react at 85°C for 70min.

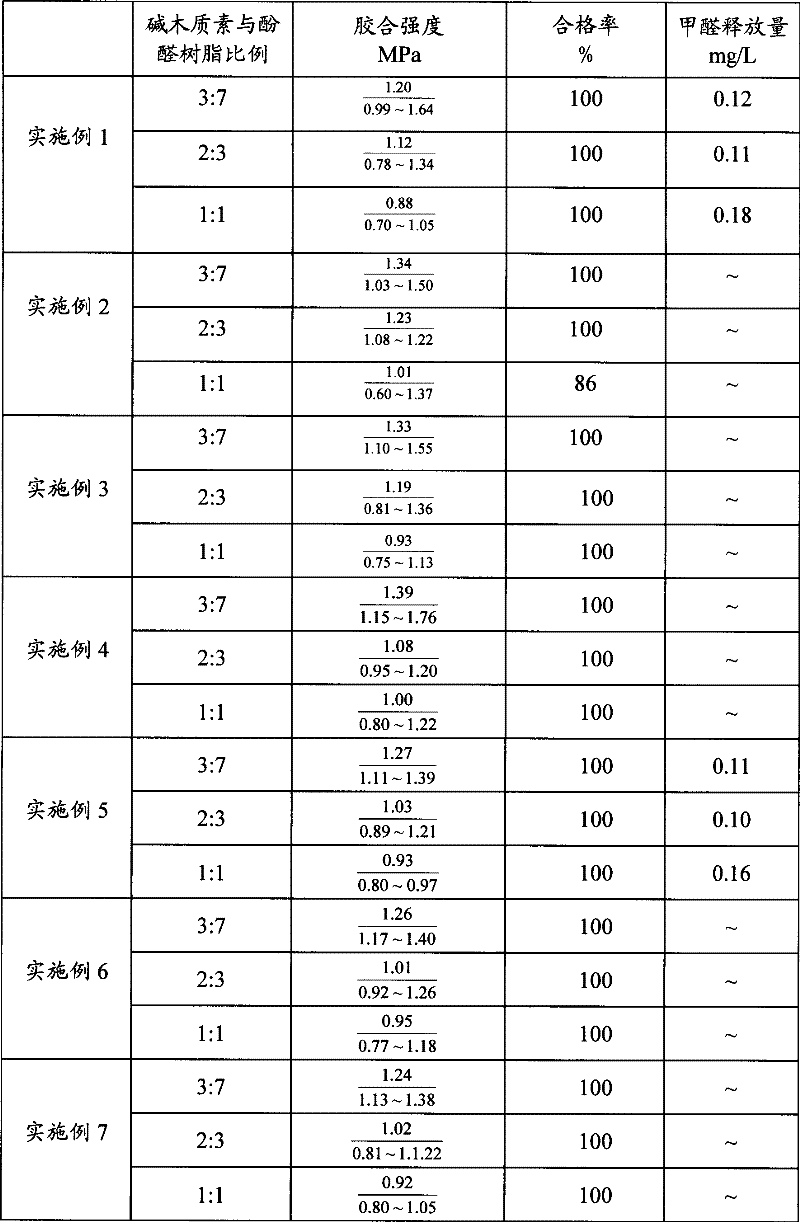

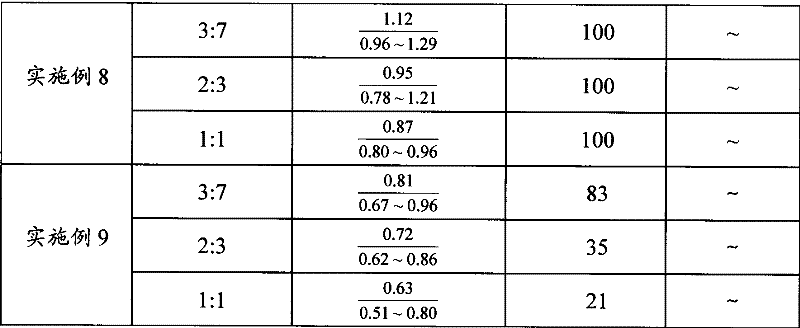

[0022] 3): Add 37g of the third batch of alkali lignin, and add a certain amount of lye to make the pH value the same as step 1, and react at 85°C for 60min. Cool the discharge. Test their performance respectively, and the results are listed in attached table 2.

[0023] The second step: the preparation of alkali lignin-phenolic resin composite adhesive:

[0024] At room temperature, mix the hydroxymethylated alkali lignin prepared in the first step with the resole phenolic resin according to 3:7, 2:3, and 1:1 (mass ratio) re...

Embodiment 2

[0026] The first step: preparation of hydroxymethylated alkali lignin:

[0027] 1): Add 40g of formaldehyde solution, 110g of the first batch of alkali lignin, and 170g of water into a 500ml four-necked flask, adjust the pH value to 12 with lye, raise the temperature to 80°C, and react for 70min.

[0028] d2): add the second batch of alkali lignin 73g, and add a certain amount of lye to ensure that its pH value is the same as step 1, and react at 80°C for 60min.

[0029] 3): Add 37g of the third batch of alkali lignin, and add a certain amount of lye to make the pH value the same as step 1, and react at 80°C for 50min. Cool the discharge. Test their performance respectively, and the results are listed in attached table 2.

[0030] The second step: the preparation of alkali lignin-phenolic resin composite adhesive:

[0031] At room temperature, mix the hydroxymethylated alkali lignin prepared in the first step with the resole phenolic resin according to 3:7, 2:3, and 1:1 (ma...

Embodiment 3

[0033] The first step: preparation of hydroxymethylated alkali lignin:

[0034]1): Add 40g of formaldehyde solution, 110g of the first batch of alkali lignin, and 170g of water into a 500ml four-neck flask, adjust the pH value to 13 with lye, raise the temperature to 80°C, and react for 70min.

[0035] 2): Add 73g of the second batch of alkali lignin, and add a certain amount of lye to ensure that its pH value is the same as that of step 1, and react at 80°C for 60min.

[0036] 3): Add 37g of the third batch of alkali lignin, and add a certain amount of lye to make the pH value the same as step 1, and react at 80°C for 50min. Cool the discharge. Test their performance respectively, and the results are listed in attached table 2.

[0037] The second step: the preparation of alkali lignin-phenolic resin composite adhesive:

[0038] At room temperature, mix the hydroxymethylated alkali lignin prepared in the first step with the resole phenolic resin according to 3:7, 2:3, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com