GaN base spinning LED and preparation method thereof

A light-emitting diode, N-type technology, applied in the field of spintronics, can solve the problems of many growth steps, GaN material carrier concentration and mobility and other electrical properties that are difficult to meet the device, long cycle, etc., to achieve a simple and easy preparation method line effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

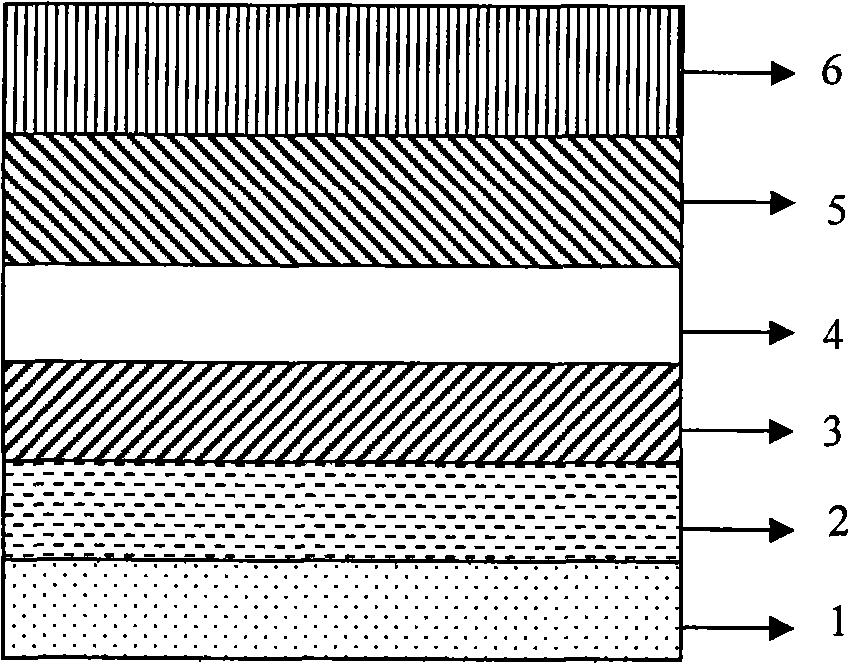

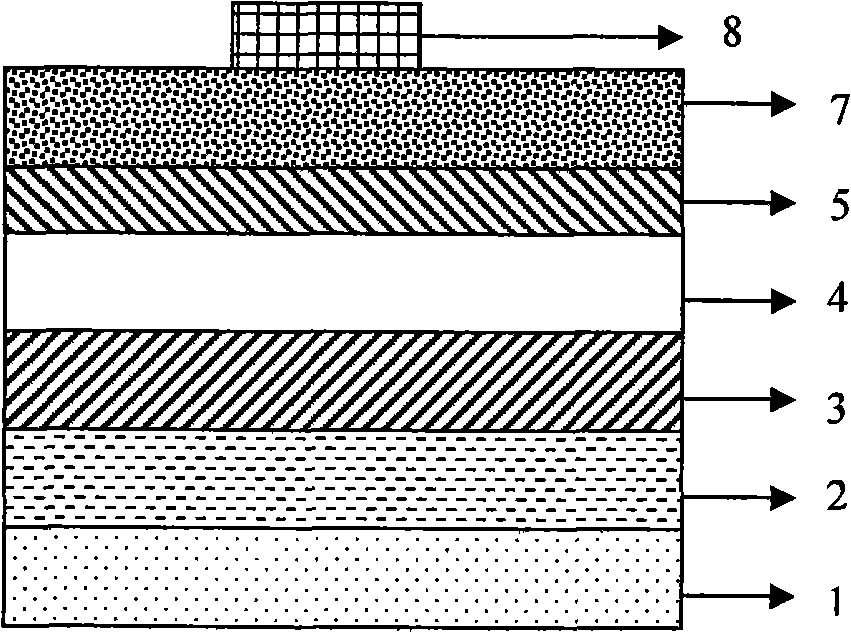

[0028] ITO materials are widely used as transparent electrodes of optoelectronic materials, and GaN-based LED technology with vertical structure is developing and gradually maturing, which has become an inevitable trend in the development of semiconductor lighting field. The present invention combines ITO magnetic material and vertical structure LED technology to prepare Spin-LED, including the following main contents and steps:

[0029] 1) Preparation of vertical GaN-based LED:

[0030] a) Fabrication of traditional GaN-based LEDs

[0031] GaN-based LED chip structures were grown on sapphire substrates by metal organic compound vapor phase epitaxy (MOCVD).

[0032] b) Preparation of P-type ohmic contacts

[0033] Deposit Ni / Au electrodes on P-GaN, and obtain ohmic contact through the alloy.

[0034] c) Substrate transfer

[0035] Cu was electroplated on Ni / Au electrodes, and the substrate was transferred.

[0036] d) Laser lift off sapphire substrate

[0037] The sample...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com