Aqueous polymer secondary dispersions for manufacturing coatings

A dispersion and secondary water technology, applied in anti-corrosion coatings, polyurea/polyurethane coatings, coatings, etc., can solve problems such as paint surface defects, paint layer bubbles, and reduce the value of paint components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

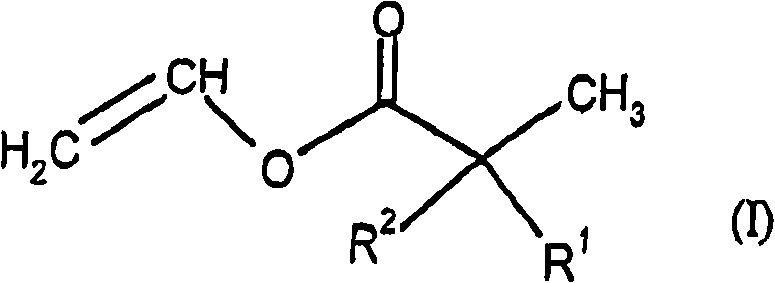

[0049] Therefore the present invention also provides the preparation method according to the polyacrylate aqueous dispersion of the present invention, it is characterized in that: in the first step (i), by monomer Ia) and Ib) prepare OH value 12-250 mgKOH / g solid hydroxy-functional hydrophobic graft base I); in a second step (ii), the monomers IIa) to IIc) are polymerized in the solution of the graft base I) obtained from step (i), wherein Monomer B) is used in step (i) and / or step (ii), preferably in step (i), and the resulting hydroxyl-functional hydrophilic polymer has an OH value of 20-250 mg KOH / g solid and 50- Acid value of 250 mg KOH / g solid and free radical initiated copolymerization of the mixture of monomers I) and II) in co-solvent C); neutralizer is then added after the preparation of the copolymer to prepare the dispersion desired ionic groups; followed by a dispersion step obtained by adding water to the copolymer or by transferring the copolymer to a volume of ...

Embodiment

[0065] raw material

[0066] I) Monomer

[0067] acrylic acid

[0068] n-butyl acrylate

[0069] n-Butyl methacrylate

[0070] 2-Ethylhexyl methacrylate

[0071] 2-Hydroxyethyl methacrylate

[0072] Methyl methacrylate

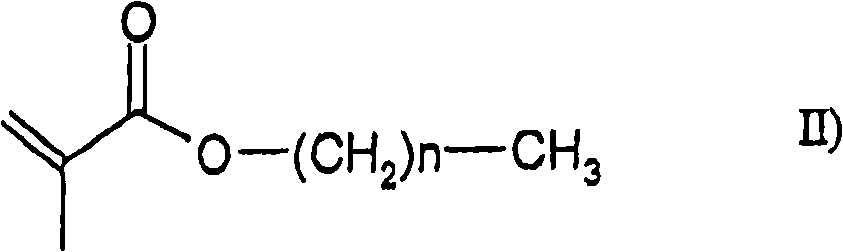

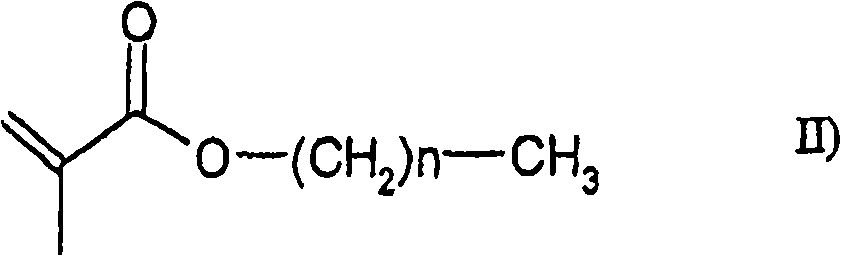

[0073] Methacrylate:

[0074]

[0075] Methacrylate 13.0 "AM009": n=1 2, synthetic lauryl methacrylate (CASNo.90551-76-1, GmbH & Co. KG, Darmstadt)

[0076] Methacrylate 17.4 "AM010": n=16.4 (CAS No.90551-84-1, GmbH & Co. KG, Darmstadt)

[0077] Stearyl methacrylate: n=17 (CAS No.32360-05-7)

[0078] II) Initiator

[0079] Di-tert-butyl peroxide

[0080] III) Solvent

[0081] : Acetate - (3-methoxy n-butyl) ester (Celanese Chemicals EuropeGmbH,) Germany

[0082] 100: Aromatics, initial boiling point (ASTM D86-05) 162°C, Exxon-Chemie, Esso Deutschland GmbH

[0083] IV) Others

[0084] VP AI 3468: Flow Control Agents, Lanxess AG, Leverkusen, DE

[0085] VP LS 2319: Hydrophilicized aliphatic polyisocyanate based on hexamethylene di...

Embodiment 2

[0099] Example 2 (according to the invention, 15% methacrylate 17.4)

[0100] 158.3 g butyl glycol and 220.6 g 100 was placed in a 6 liter reaction vessel equipped with a stirrer, cooling device and heating device and heated to 138°C. At this temperature, a mixture consisting of 8 g of butyl glycol and 8 g of di-tert-butyl peroxide was added dropwise over 30 minutes. Then within 5 hours, a mixture consisting of 34.3 g butyl glycol and 34.3 g di-tert-butyl peroxide, and 680.0 g methyl methacrylate, 445.0 g 2-hydroxyethyl methacrylate, 482.2 A mixture of g n-butyl acrylate and 375.0 g methacrylate 17.4. Immediately thereafter, a mixture consisting of 8.0 g butyl glycol and 20.0 g di-tert-butyl peroxide, and a mixture consisting of 127.5 g methyl methacrylate, 180.0 g 2-hydroxyethyl methacrylate, 100.0 g n-butyl acrylate ester and 60 g of acrylic acid. The mixture was then stirred at 138° C. for 1 hour, then cooled to 100° C. and 77.9 g of N,N-dimethylethanolamine were added...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com