Method for producing hydrogen using photosynthetic bacteria

A technology for producing hydrogen and photosynthetic bacteria, applied in the direction of microorganism-based methods, biochemical equipment and methods, microorganisms, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

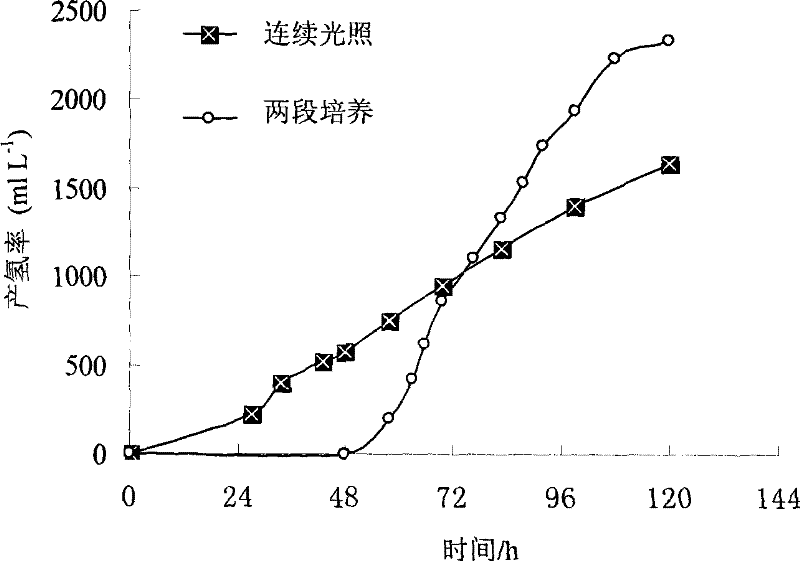

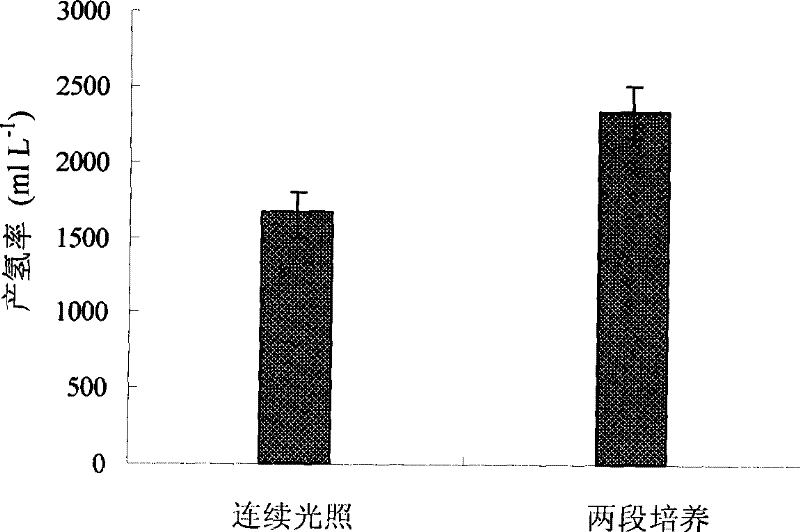

[0074] Embodiment 1: Use R. rubrum ATCC11170 to prepare hydrogen under the condition of continuous light of incandescent lamp

[0075] Hydrogen gas is produced as follows:

[0076] (1) Strain activation: R. rubrum ATCC11170 was inoculated on SMN plate medium, and cultured at 30°C for 5 days; the obtained activated R. rubrum colonies turned dark red, and the colony diameter reached 2 mm or more and could be used in subsequent steps.

[0077] (2) Seed culture: Inoculate the activated bacterial classification of step (1) in a 50ml Erlenmeyer flask with 30-40ml SMN liquid medium, and inoculate at 30°C and a shaking speed of 100rpm in a shaking incubator produced by Harbin Donglian Company The seed culture solution was obtained by shaking and culturing in the dark for 24 hours; the obtained seed culture solution had a light absorption value at 600 nm greater than 2.5 and could be used in subsequent steps.

[0078] (3) Fermentation culture: using the volume of 25ml anaerobic tubes ...

Embodiment 2

[0083] Example 2: Using R. rubrum ATCC11170 to prepare hydrogen in two-stage light culture with incandescent lamp as light energy source (light filter culture for 48h)

[0084] Hydrogen gas is produced as follows:

[0085] The present embodiment carries out according to the steps (1), (2) and (4) of embodiment 1, and step (3) is carried out according to the following manner:

[0086] Photosynthetic hydrogen evolution under two-stage light culture.

[0087] The first stage is filter culture:

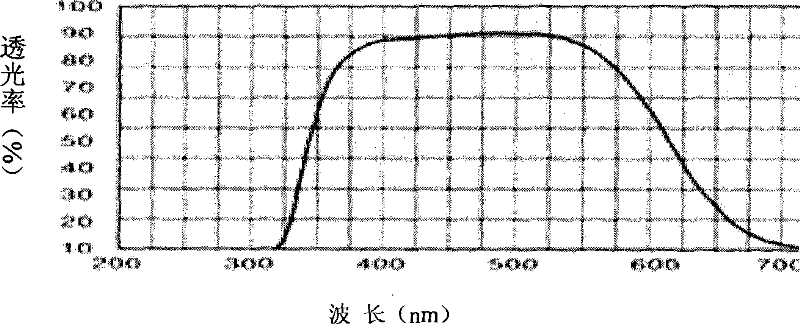

[0088] Firstly, take an anaerobic tube sold under the trade name anaerobic culture tube by the College of Life Sciences of Capital Normal University, fill it with the inoculation culture solution obtained in step (2), and seal the anaerobic tube in a blue glass container. Inside the carton, the top of the carton is covered with tinfoil, and the incandescent lamp provides light energy. The characteristics of the blue glass are as described above. The light intensity on the surface of the...

Embodiment 3

[0092] Example 3: Using R. rubrum ATCC11170 to produce hydrogen by two-stage light culture with incandescent lamp as light energy source

[0093] Hydrogen gas is produced as follows:

[0094] The present embodiment carries out according to the steps (1), (2) and (4) of embodiment 1, and step (3) is carried out according to the following manner:

[0095] Photosynthetic hydrogen evolution under two-stage light culture after different light-filtered culture times.

[0096] The first stage is filter culture:

[0097] First, take an anaerobic tube sold under the trade name anaerobic culture tube by the School of Life Sciences of Capital Normal University, fill it with the inoculation culture solution obtained in step (2), and place the inoculated anaerobic tube in a blue-blue tube. In the glass carton, the top of the carton is covered by tinfoil, and the incandescent lamp provides light energy. The light intensity on the surface of the carton installed with blue glass is 2800lux ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com