Sonic surface wave pressure sensor using composite mold

A technology of pressure sensor and surface acoustic wave, which is applied in the measurement of fluid pressure using piezoelectric devices, the measurement of the property force of piezoelectric devices, and the measurement of fluid pressure. Physical position consistency problem, poor stress concentration effect, damage to pressure sensor and other problems, to achieve the effect of improving long-term stability, good accuracy and reducing temperature gradient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

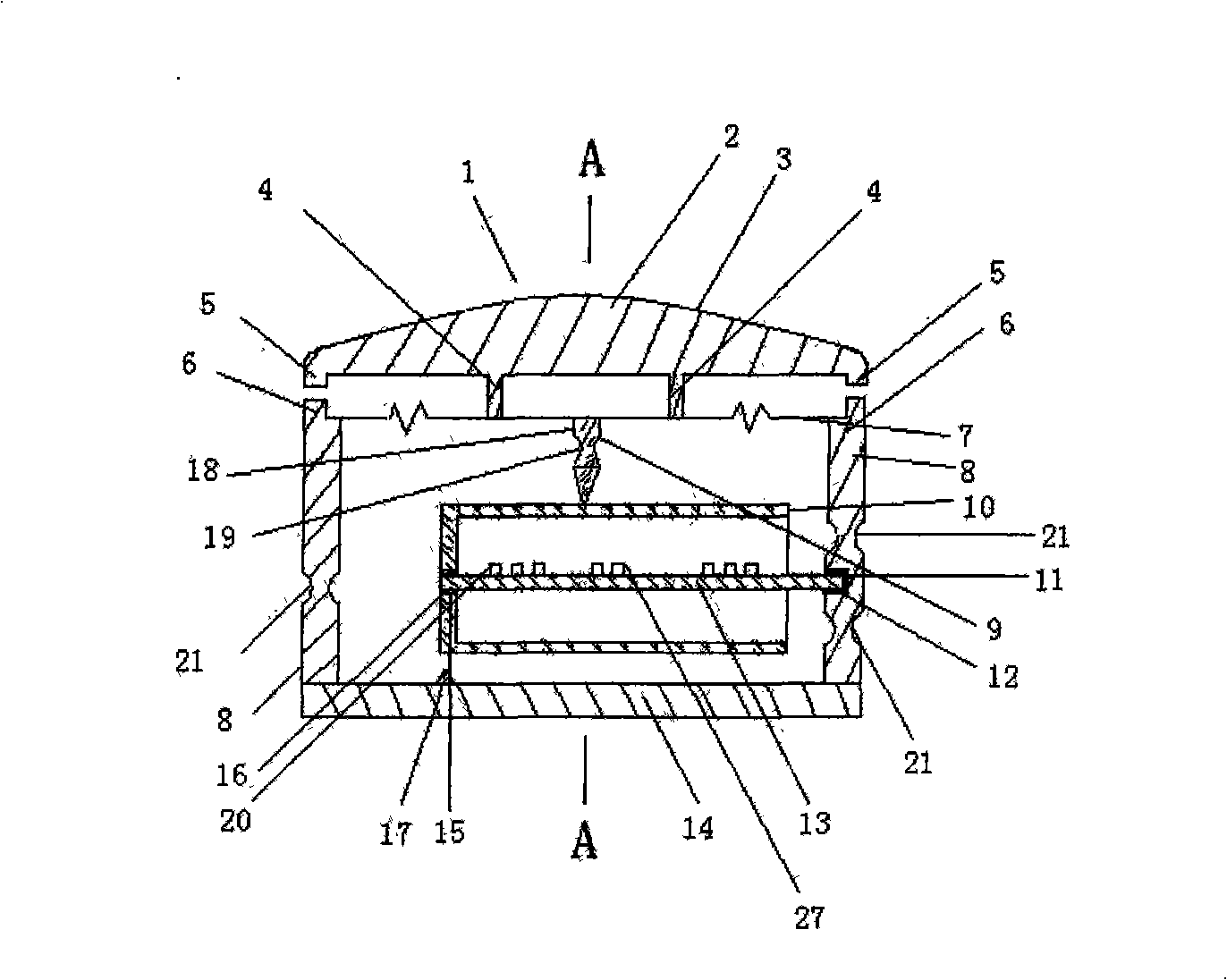

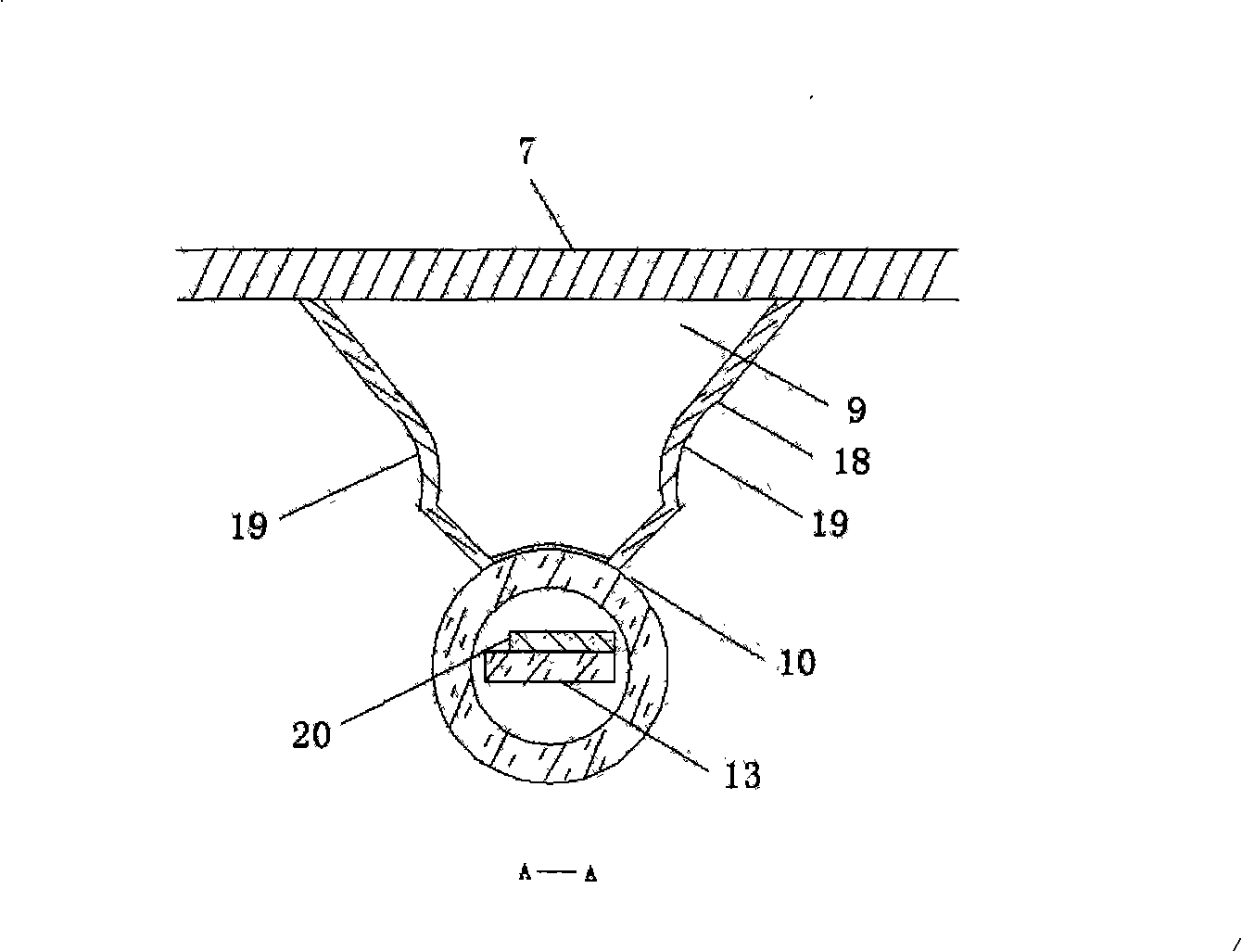

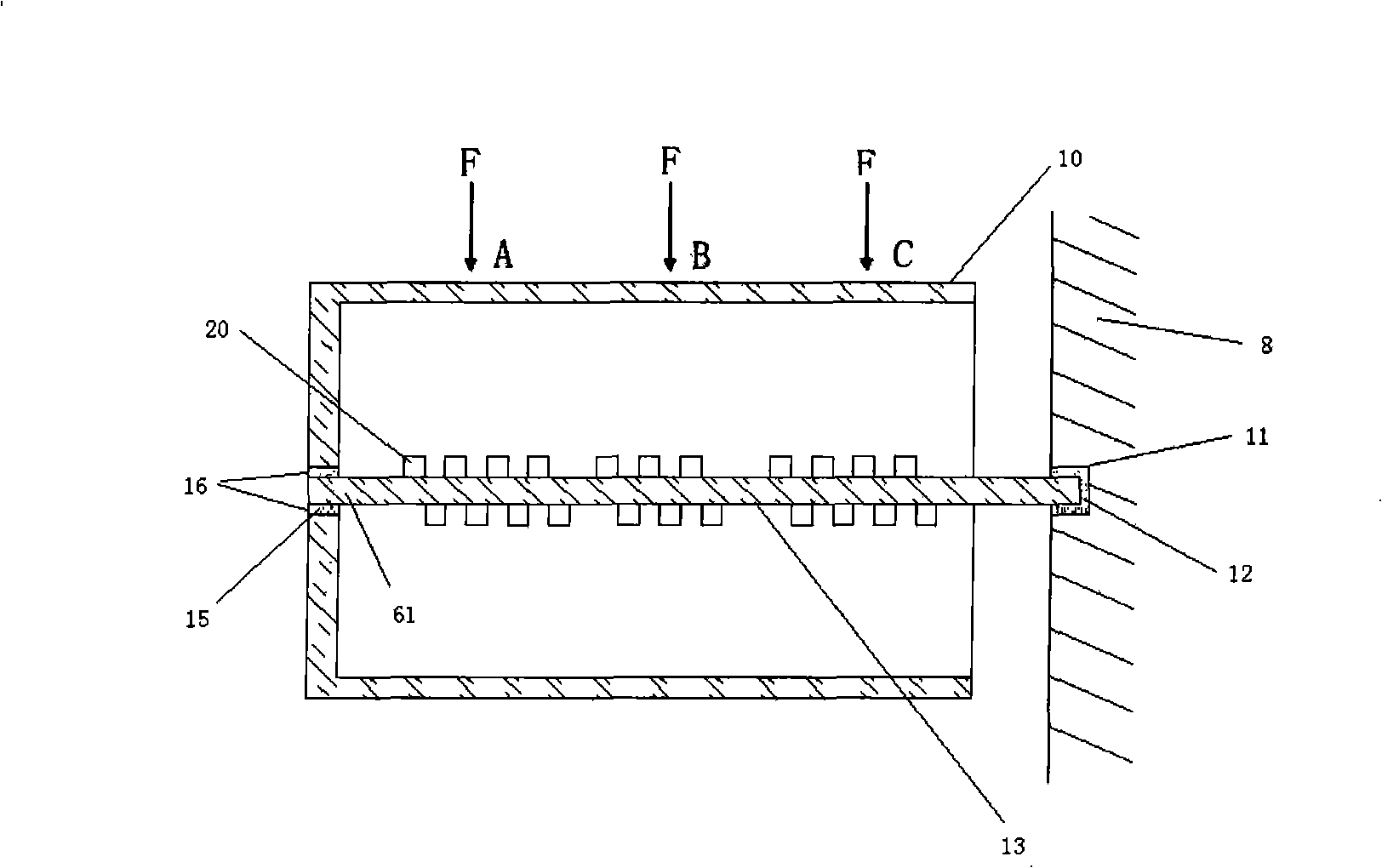

[0046] Such as figure 1 , figure 2 , image 3 As shown, this embodiment includes: mushroom-shaped pressurized cap 2, metal force guide column 4, hard spherical shell pressure guide metal diaphragm 7, metal shell side wall 8, force guide thimble piece 9, force guide cylinder 10, quartz The cantilever beam type sensitive element 13, the bottom shell 14, and the overvoltage protection device 17, wherein: the hard-core spherical shell pressure-guiding metal diaphragm 7, the metal shell side wall 8, and the bottom shell 14 form an airtight container, and the hard-core spherical shell The upper surface of the pressure-guiding metal diaphragm 7 is connected to the mushroom-shaped pressure cap 2 through the metal force-guiding column 4, and the lower surface is fixed with a force-guiding thimble 9, which is rigidly connected with the force-guiding cylinder 10, and the force-guiding cylinder 10 There is a quartz cantilever beam sensitive element 13 inside. One end of the quartz cant...

Embodiment 2

[0064] Such as Image 6 As shown, the structure difference between this embodiment and Embodiment 1 is that the Rayleigh wave mode SAW device 20 is arranged on the upper surface of the piezoelectric quartz wafer 21, and the surface-grazing body wave SSBW device 27 is arranged on the piezoelectric quartz wafer 21. On the lower surface, the propagation direction of the surface acoustic wave forms an angle of 50° with the X-axis of the wafer, and the propagation direction of the grazing body wave 35 excited by the SSBW device 27 and the Rayleigh wave 34 excited by the Rayleigh wave mode SAW device 20 form an angle of 90° . The Rayleigh wave mode SAW device 20 is responsible for measuring temperature, and the skimming body wave SSBW device 27 is responsible for measuring pressure.

[0065] Obviously, the second embodiment adopts the combination of the Rayleigh wave mode SAW device 20 and the skimming body wave SSBW device 27 to realize the measurement of pressure and temperature ...

Embodiment 3

[0067] Such as Figure 7 As shown, the structure difference between the present embodiment and the first embodiment is that the Rayleigh wave mode SAW device 20 consists of an interdigital transducer 25 and three second reflection grids 35, 36 and 37 (or more than three) Arranged in a row to form a reflective delay line (label) structure, the SSBW device 27 is composed of a second interdigital transducer 28 and two third reflective grids. The Rayleigh wave mode SAW device 20 is arranged on the upper surface of the piezoelectric quartz wafer 61, and the surface-grazing body wave SSBW device 27 is arranged on the lower surface of the piezoelectric quartz wafer 61, and both have different depths of energy distribution on the piezoelectric quartz wafer 61, Through their three-dimensional intersection, the measurement of pressure and temperature is realized.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com