Adiabatic calorimeter and heat measuring system

An adiabatic heat and calorimeter technology is applied in the field of material heat capacity measuring instruments, which can solve the problems of large temperature variability, large volume, and difficulty in measuring substances with small acquisition amounts, so as to improve stability and accuracy, The device has compact structure and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

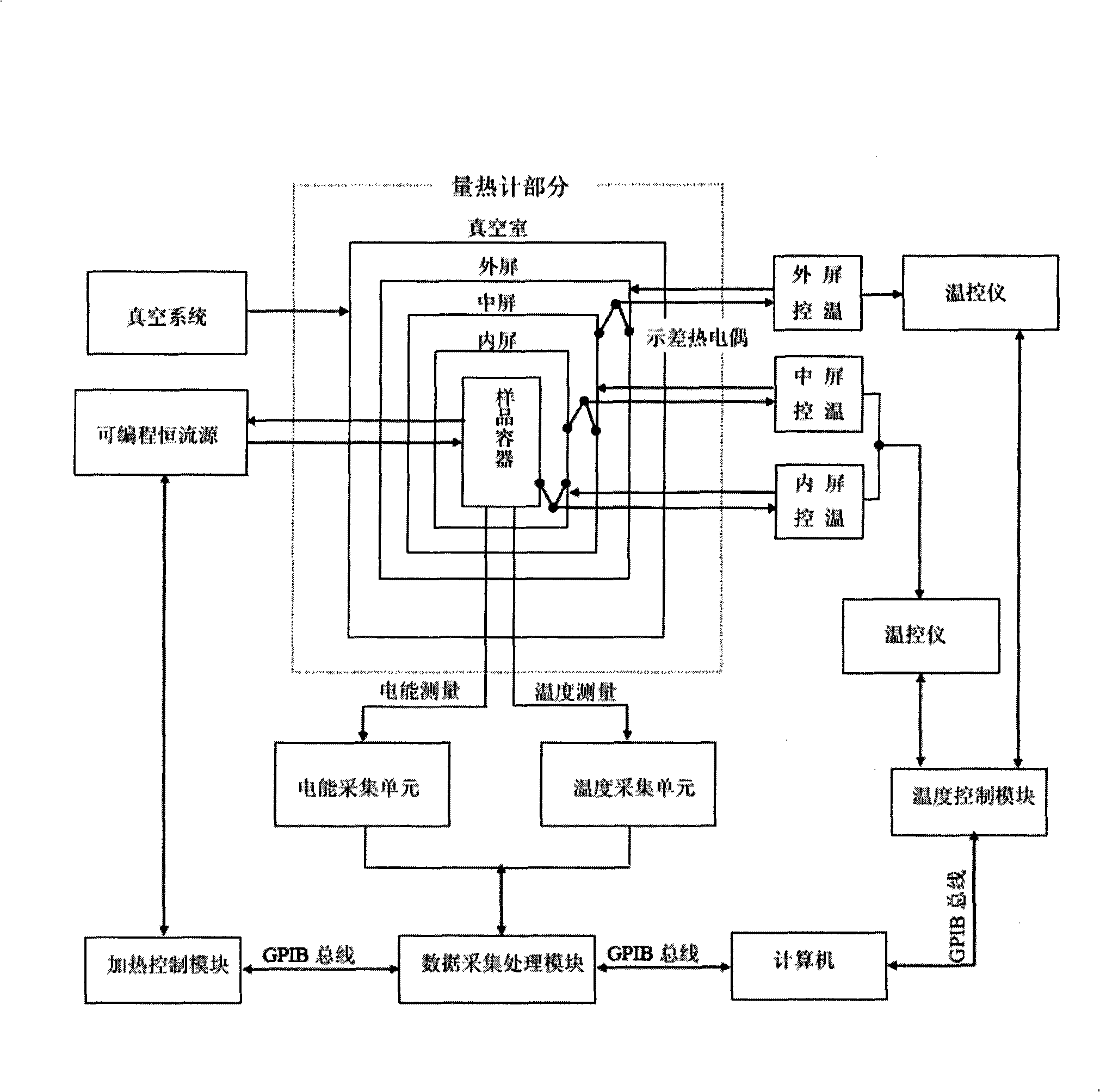

[0031] The invention not only includes the calorimeter and the calorimetric system, but also includes the software control principle and process of the calorimetric system.

[0032] 1. Calorimeter

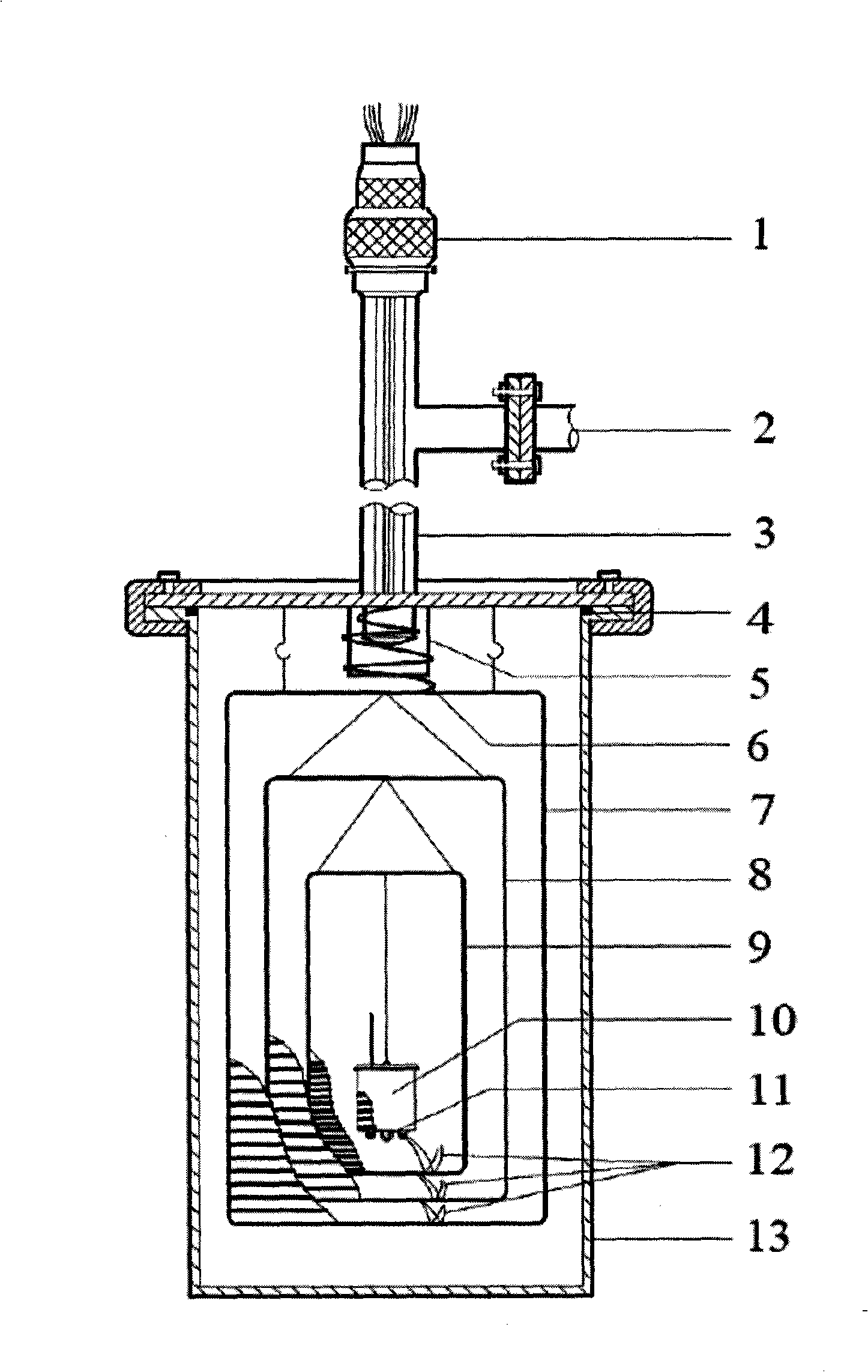

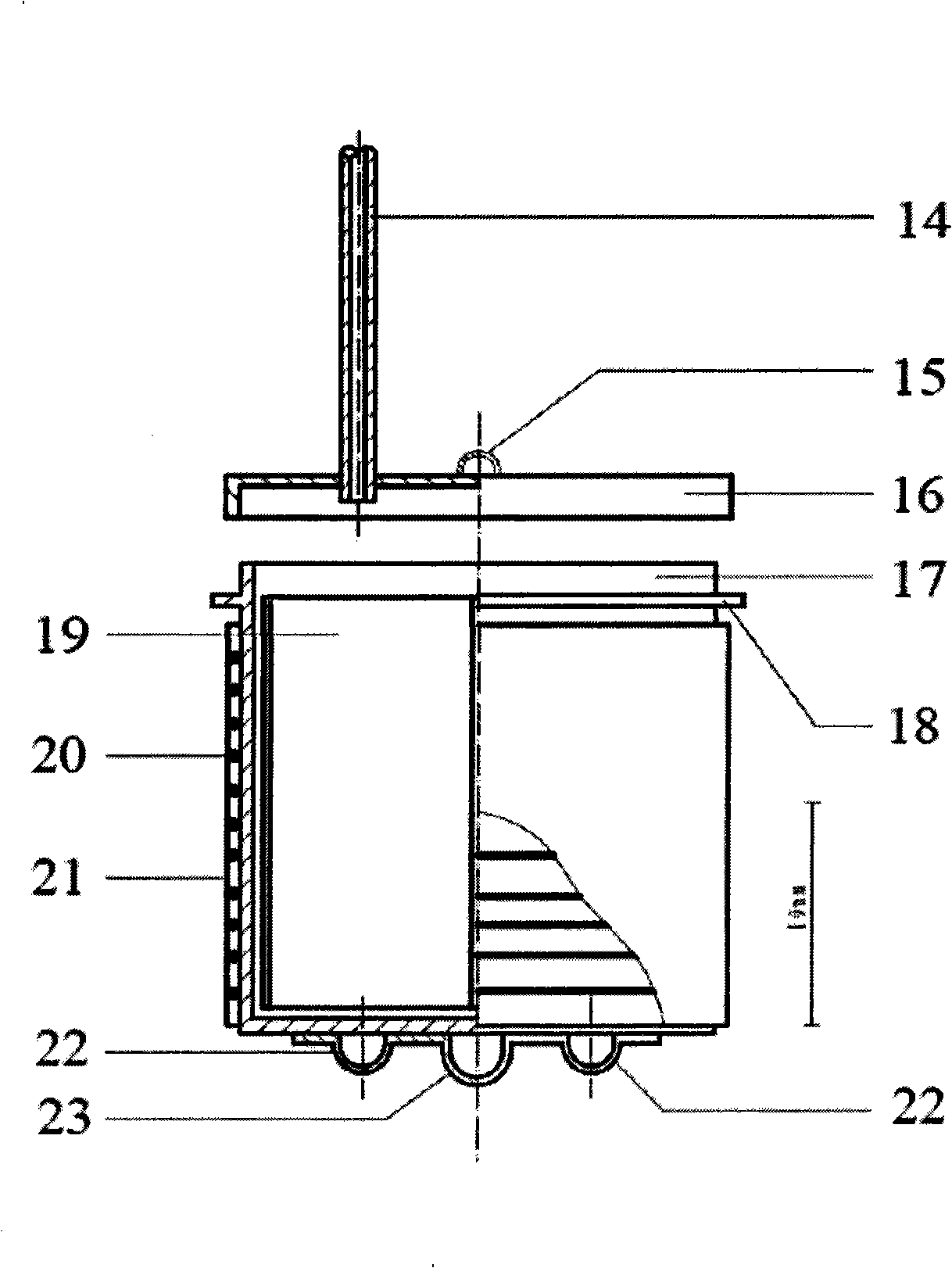

[0033] An adiabatic calorimeter, such as figure 1 shown. The calorimeter adopts three-layer insulation screen temperature control, including vacuum sealing connector 1, vacuum system valve 2, vacuum conduit 3, sealing gasket 4, wire temperature control ring 5, wire bundle 6, outer insulation screen 7, middle insulation screen 8. Inner thermal insulation screen 9, sample container 10, thermometer and thermocouple socket 11, differential thermocouple 12 and vacuum chamber 13.

[0034]The vacuum chamber 13 is a closed cylinder with an upper cover; the outer heat insulation shield 7, the middle heat insulation shield 8 and the inner heat insulation shield 9 are all cylindrical structures, which are composed of an upper cover, a cylinder body and a lower cover. There is a detachable ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com