Heat engine plant A335P92 steel welding technique

A welding process and technology of thermal power plants, applied in welding equipment, arc welding equipment, manufacturing tools, etc., can solve problems such as infancy, early failure of type IV cracking, weld metal toughness lower than base metal, etc., to reduce resistance, Effect of improving thermal efficiency and economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

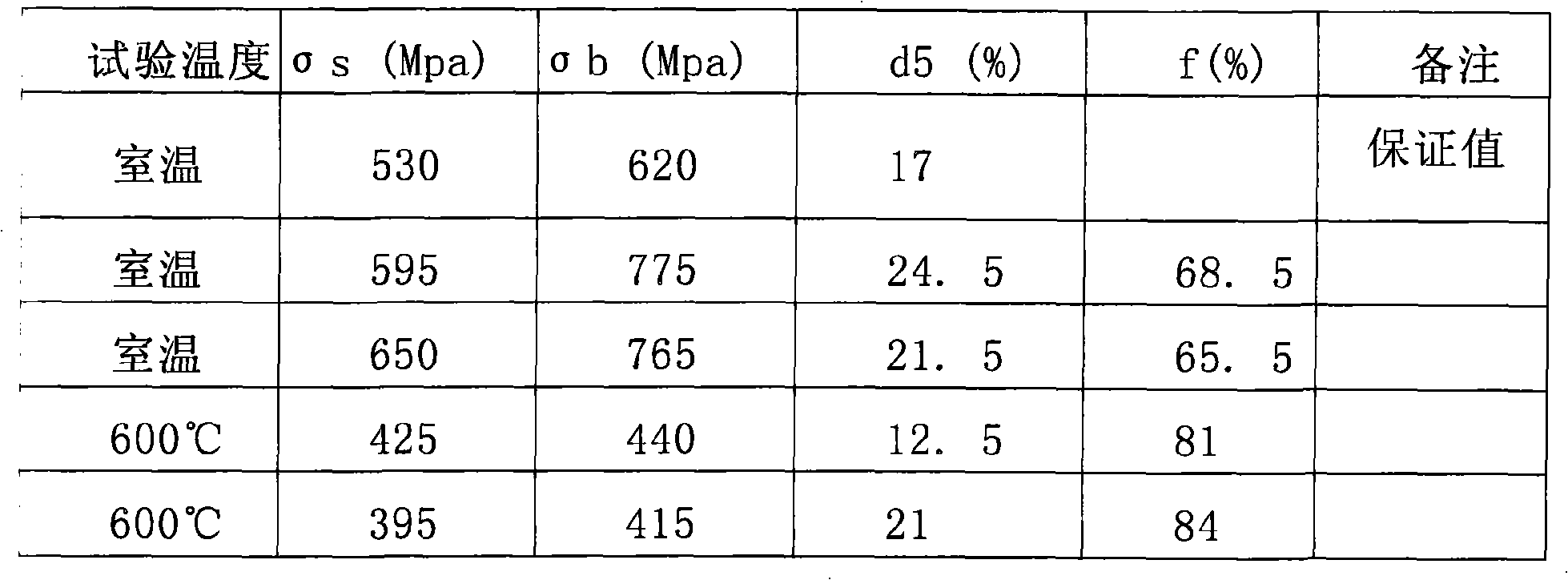

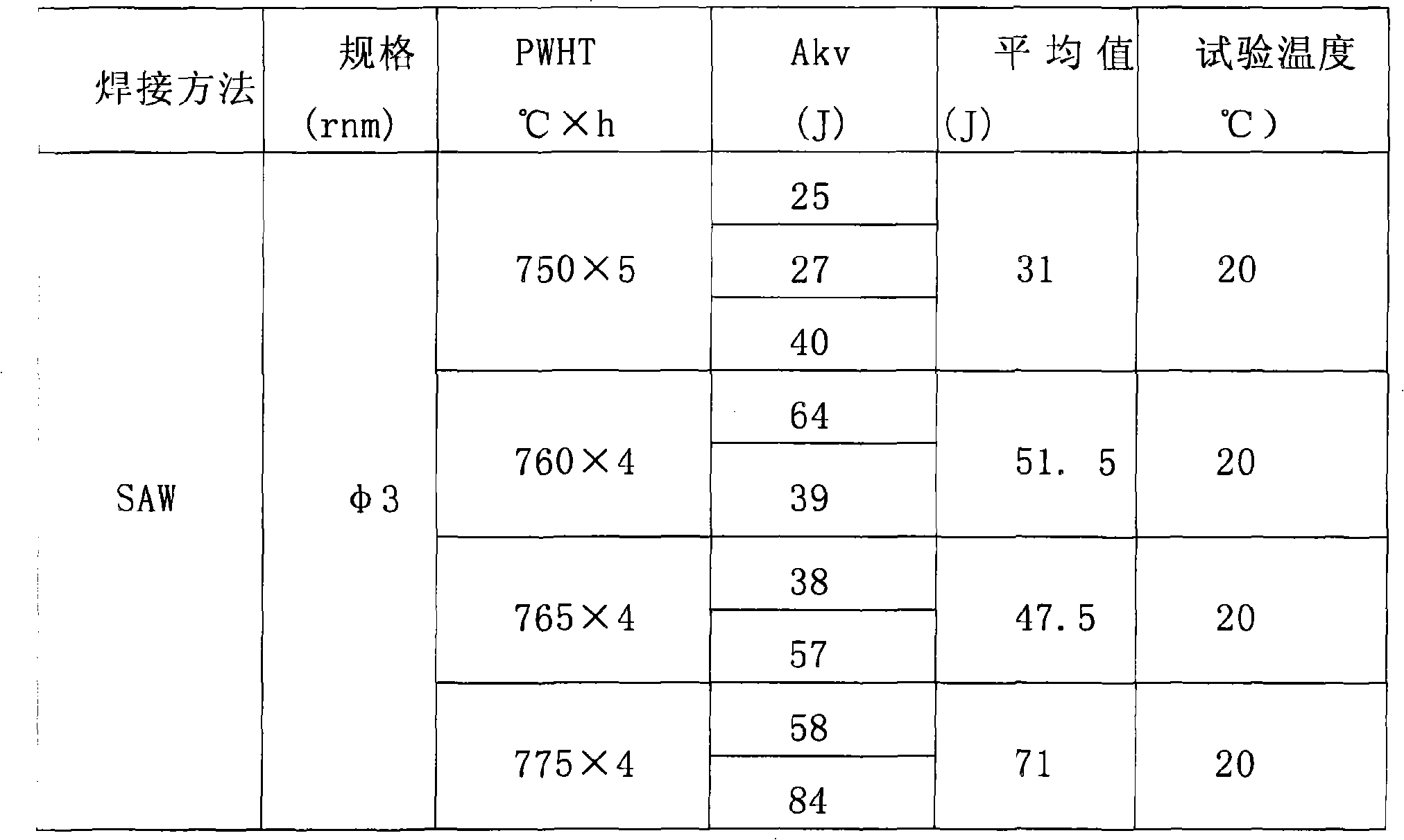

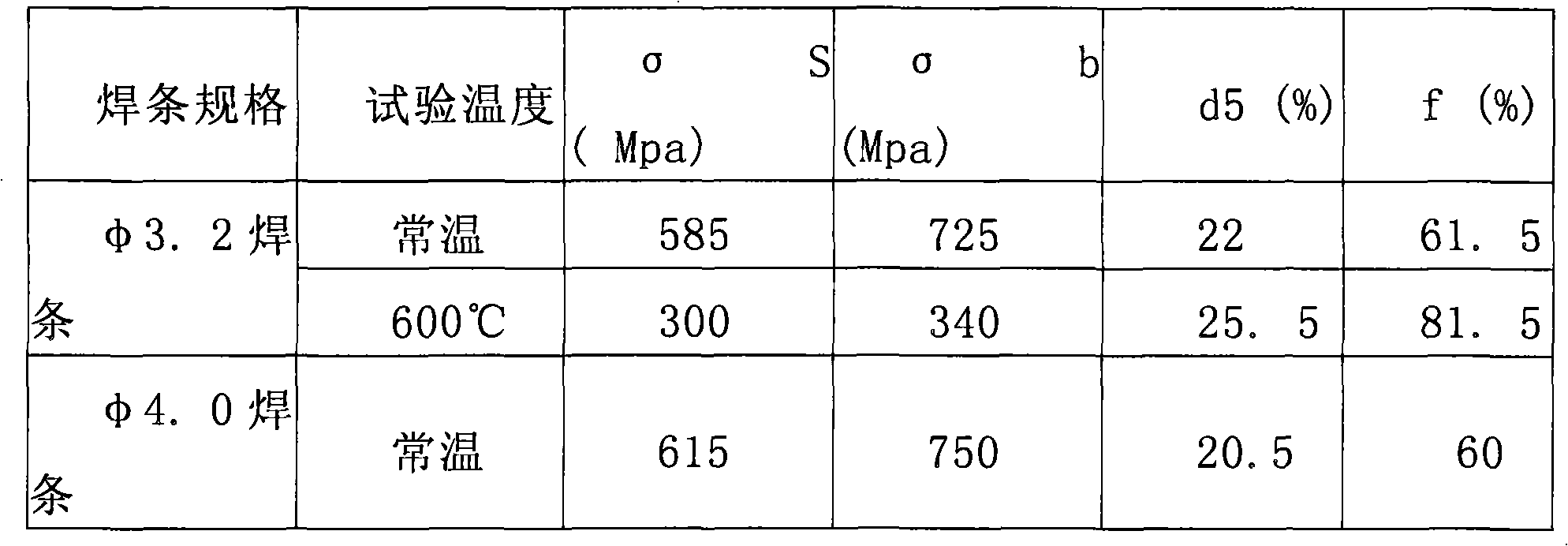

[0040] The welding methods used in the present invention include manual arc welding (SMAW), argon tungsten arc welding (GTAW) and automatic submerged arc welding (SAW). Through test comparison and welding procedure evaluation, welding materials are selected and welding procedures are formulated to ensure that the mechanical properties of welded joints meet the requirements, and the key point is to ensure that welded joints have high impact toughness and durable strength. Its process method comprises following process steps:

[0041] (1) Select and determine the welding materials applicable to the project

[0042] (2) Select the welding method

[0043] (3) Determine the welding process parameters

[0044] (4) Determine the post-weld heat treatment temperature and method

[0045] (5) Performance testing and analysis of weld seam and heat-affected zone

[0046] (6) Welding procedure qualification

PUM

| Property | Measurement | Unit |

|---|---|---|

| creep rupture strength | aaaaa | aaaaa |

| creep rupture strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com