Die grid for producing composite block and casting forming method of composite block

A composite block and formwork technology, which is applied in the direction of ceramic forming machines, molds, manufacturing tools, etc., can solve the problems of less block layers, high production costs, and loss of strength, and achieve low overall cost, short construction period, dry down effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

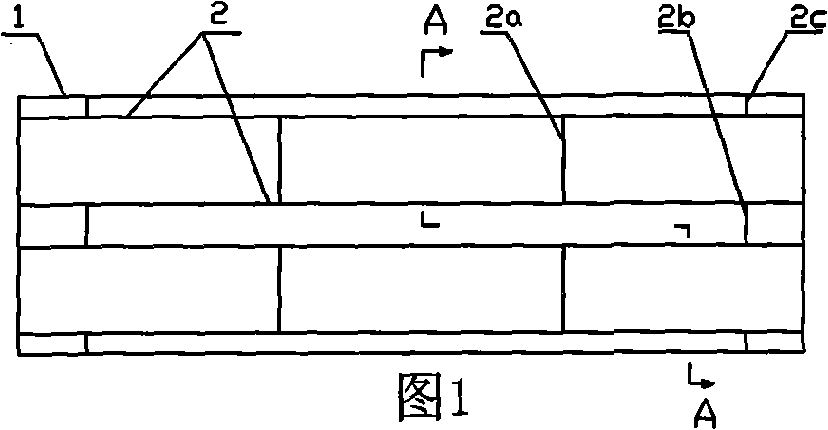

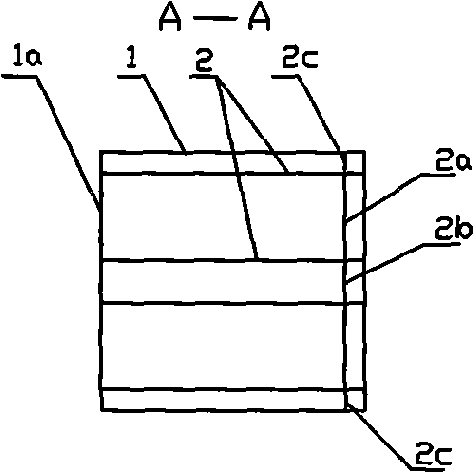

[0034] Embodiment one: the mold frame basic form that the present invention provides is as shown in Figure 1, figure 2 As shown, it includes a rectangular peripheral frame 1 and a frame bottom 1a that is movably connected and matched. At least one pair of partition plates 2 (2 pairs in this example) are arranged in the peripheral frame 1, and each pair of partition plates 2 is provided with The connection plate 2a is also provided with a connection plate 2b between every two pairs of partition plates 2, and a positioning plate 2c is provided near the part of the outer frame, so that all the partition plates, connection plates, and positioning plates are integrated, and formed with the peripheral frame. Active fit that can be inserted or removed. Such as figure 2 As shown, all connecting plates and positioning plates can only be arranged on a small section above, and cannot affect the circulation of the cavity below.

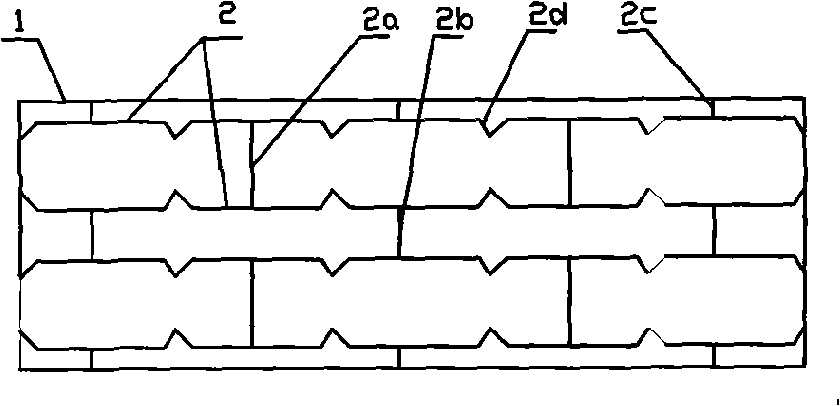

[0035] Such as image 3 Shown, in order to demarcate the...

Embodiment 2

[0036] Embodiment two: if Figure 5 shown in image 3 On the basis of the mold frame shown, a pair of inner partitions 4 are arranged between each pair of partition plates 2, and each inner partition 4 is in the division range of the corresponding V-shaped groove mark, and the connecting plates 2e and Splitter board 2 connection.

[0037] Such as Image 6 As shown, one can go further, in Figure 5 On the basis of each pair of inner partitions, an inner frame 5 is connected.

[0038] It can be seen from the pouring mold frame described in Embodiment 1 and Embodiment 2 that the partition plate, inner partition board, and inner frame set in the peripheral frame can also have other combinations, and its essence is to divide the inside of the peripheral frame into different parts. Each section can be poured with different block forming materials.

Embodiment 3

[0039] Embodiment three: adopt pouring mold frame shown in Fig. 8, it is in Figure 5 It is changed on the basis of the pouring formwork shown, that is, four pairs of dividing plates 2 are arranged in the outer frame 2, and a polystyrene foam board 9 is respectively placed between each pair of inner dividing plates 4, and it is close to the inner dividing plate. 4 The hypotenuses 4a at both ends are positioned. As shown in Fig. 9, a layer of rubber pad 1b is compounded on the frame bottom 1a of the peripheral frame 1, and its effect is that when the peripheral frame 1 is demoulded, the cast blocks are easily separated from the rubber pad.

[0040] The mold frame shown in Fig. 8 has formed the pouring area of three kinds of materials, namely between the dividing plate 2 and the peripheral frame 1 and the zone 12 between every pair of dividing plates 2 between every pair of dividing plates, dividing plate 4 and poly The area 11 between the benzene foam boards 9. Such as Fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com