Membrane wrapping sustained-release urea and producing method thereof

A slow-release urea and coating technology, applied in the field of plant nutrients, can solve the problems of limited slow-release effect, poor slow-release effect, and inability to form a waterproof surface coating, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Embodiment 1: a kind of method for preparing coated-type slow-release urea, comprises following processing step:

[0044] A) Use granular urea with a particle size of ¢2.4-4mm, and dry it at 60-80°C for about 40 minutes;

[0045] B) Uniformly coat liquid polyisocyanate on the surface of flowing granular urea, the molar mass of polyisocyanate used is 5 times of the required molar mass to react with the surface of granular urea, and the coating time is 3 minutes, so that the polyisocyanate is mixed with urea on the surface of granular urea The reaction produces biuret;

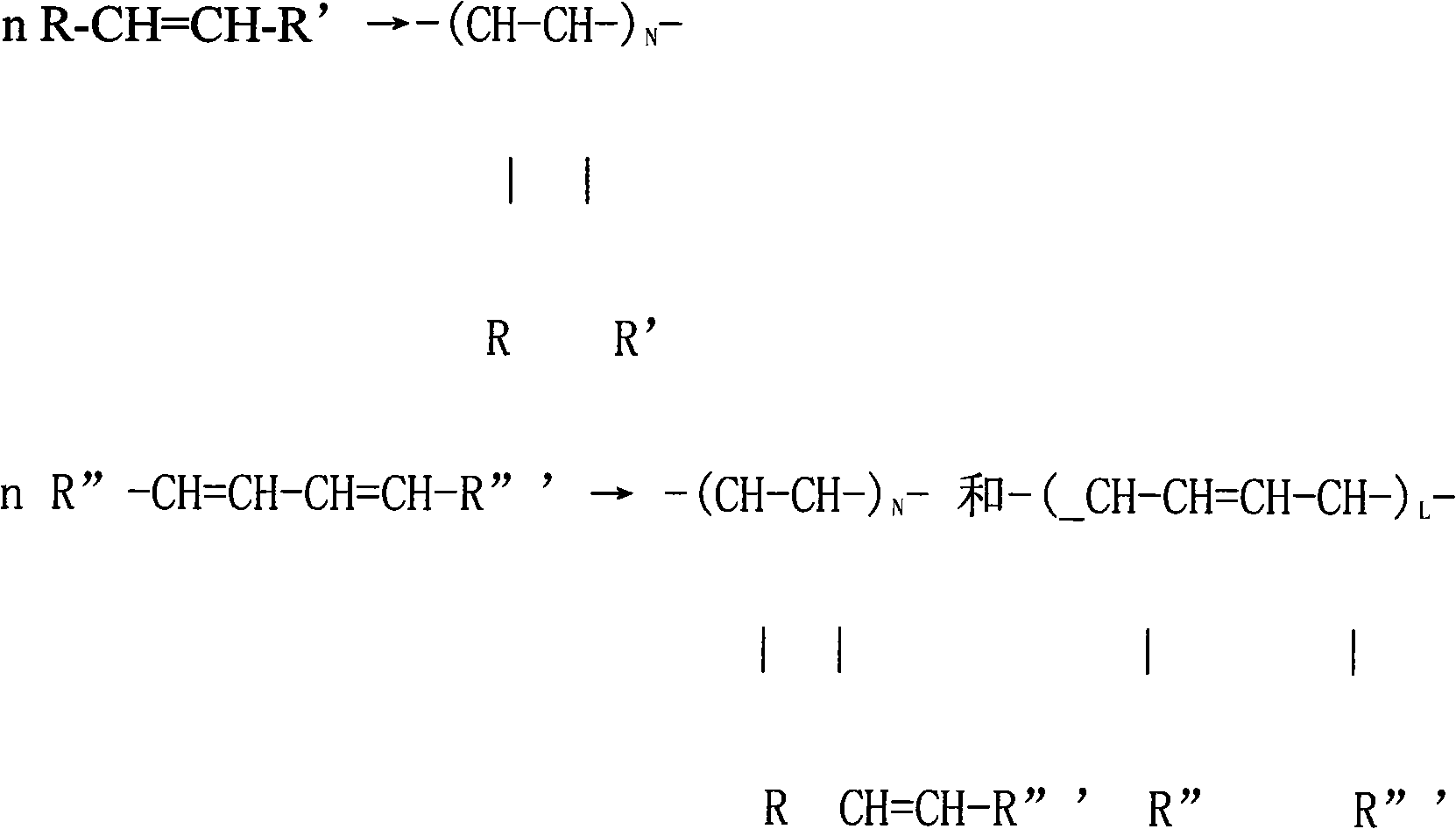

[0046] C) At 40-60°C, evenly coat the mixed liquid consisting of double bond-containing polyols, oil substances, initiators, catalysts, and solvents on the surface of granular urea for 5 minutes, so that the double-bond-containing The bonded polyol reacts with the remaining polyisocyanate on the surface of the granular urea to generate polyurethane, while the double bond-containing polyol and oily substa...

Embodiment 2

[0056] A method for preparing coated sustained-release urea, comprising the following process steps:

[0057] A) Use granular urea with a particle size of ¢2.4-4mm, and dry it at 80-1000°C for about 10 minutes;

[0058] B) Liquid polyisocyanate is evenly coated on the surface of the flowing granular urea, the molar mass of the polyisocyanate used is 10 times that required for the reaction with the surface of the granular urea, and the coating time is 10 minutes, so that the polyisocyanate is on the surface of the granular urea and urea The reaction produces biuret;

[0059] C) At 80-100°C, uniformly coat the mixed liquid consisting of double bond-containing polyols, oil substances, initiators, catalysts, and solvents on the surface of granular urea, and the coating time is 10 minutes. The bonded polyol reacts with the remaining polyisocyanate on the surface of the granular urea to generate polyurethane, while the double bond-containing polyol and oily substances are polymeriz...

Embodiment 3

[0071] A method for preparing coated sustained-release urea, comprising the following process steps:

[0072] A) Use granular urea with a particle size of ¢2.4-4mm, and dry it at 70-90°C for about 30 minutes;

[0073] B) Evenly coat liquid isocyanate on the surface of flowing granular urea, the molar amount of liquid polyisocyanate used is 8 times of the molar amount needed to react with the surface of granular urea, and the coating time is 7 minutes, so that polyisocyanate is on the surface of granular urea and urea The reaction produces biuret;

[0074] C) At 70-90°C, uniformly coat the mixed liquid consisting of double bond-containing polyols, oil substances, initiators, catalysts, and solvents on the surface of granular urea, and the coating time is 8 minutes. The bonded polyol reacts with the remaining polyisocyanate on the surface of the granular urea to generate polyurethane, and simultaneously the polyol and oily substances polymerize to form a free radical polymer, w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com