Method for compounding and entrapping tea polyphenols through debranched starch and xanthan gum

A technology of xanthan gum and tea polyphenols, which is applied in the field of stable microcapsule preparation of functional factors, can solve the problems of weak gel formation ability, poor digestion resistance, and starch restriction, and achieve short half-life, obvious effect, and bioavailability low rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

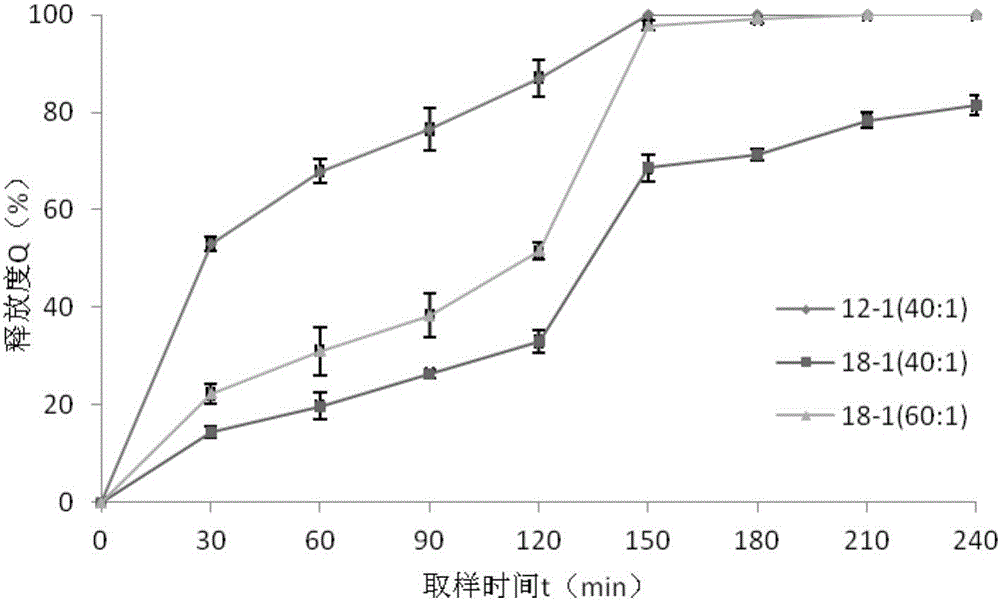

Embodiment 1

[0042] 1. Use 0.01mol / L sodium acetate buffer solution of pH 5.5 in the gelatinization pot to prepare ordinary cornstarch into cornstarch milk with a mass fraction of 10%, and then heat it with saturated steam in the gelatinization pot with a stirring paddle Gelatinization for 30 minutes, the stirring speed is controlled by a speed-regulating stirring motor, and the jacket heating belt of the pot is controlled by a steam regulating valve.

[0043] 2. After the corn starch milk is completely gelatinized, use a plate heat exchanger for heat exchange to reduce the temperature of the starch milk to within the range of 50-60°C. Add 12 U / g of pullulanase at 55° C., and after debranching reaction for 3 hours, the relative debranching degree at this time can be ensured to be above 50% by nuclear magnetic resonance. Pump the enzymolysis solution into the ejector and directly contact with high-temperature steam, maintain a high temperature of 120°C in the storage tank for 3-5 minutes to...

Embodiment 2

[0047] 1. Use 0.01mol / L sodium acetate buffer solution of pH 5.5 to prepare waxy corn starch milk with a mass fraction of 20% in a gelatinization pot, and then put it in a gelatinization pot with a stirring paddle Heat gelatinization with saturated steam for 30 minutes, control the stirring speed with a speed-regulating stirring motor, and control the jacket heating belt of the pot body by a steam regulating valve.

[0048] 2. After the waxy corn starch milk is completely gelatinized, heat exchange is performed with a plate heat exchanger to reduce the temperature of the starch milk to within the range of 50-60°C. Add 18u / g pullulanase at 55°C, and after debranching reaction for 2 hours, the relative debranching degree at this time can be ensured to be above 50% by nuclear magnetic resonance. Pump the enzymatic hydrolysis solution into the ejector and directly contact with high-temperature steam, and maintain a high temperature of 120°C for 3-5 minutes in the storage tank to c...

Embodiment 3

[0052] 1. Use 0.01mol / L sodium acetate buffer solution of pH 5.5 in the gelatinization pot to prepare ordinary rice starch into rice starch milk with a mass fraction of 40%, and then heat it with saturated steam in the gelatinization pot with a stirring paddle Gelatinization for 30 minutes, the stirring speed is controlled by a speed-regulating stirring motor, and the jacket heating belt of the pot is controlled by a steam regulating valve.

[0053] 2. After the rice starch milk is completely gelatinized, use a plate heat exchanger for heat exchange to reduce the temperature of the starch milk to within the range of 50-60°C. Add 18u / g isoamylase at 55°C, and after debranching reaction for 1 hour, the relative degree of debranching at this time can be ensured to be above 50% by nuclear magnetic resonance. Pump the enzymatic hydrolysis solution into the ejector and directly contact with high-temperature steam, and maintain a high temperature of 120°C for 3-5 minutes in the stora...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com