Amoxicillin capsule and preparation method thereof

A technology of amoxicillin capsules and amoxicillin, applied in the field of western medicine preparations, can solve the problems of large individual differences in capsule dissolution, reducing the effect of co-solvent and co-solvent, and increasing the relative amount of co-solvent added. release effect, volume reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

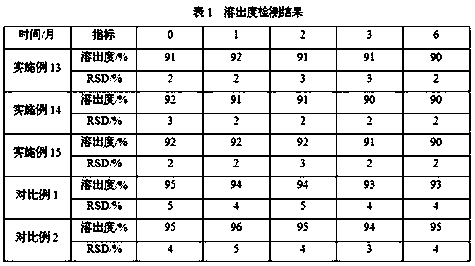

Examples

Embodiment 1

[0026] An amoxicillin capsule is prepared from the following raw materials in parts by weight: 200 parts of amoxicillin, 5-10 parts of sodium carboxymethylcellulose, 1-1.5 parts of talcum powder and 0.5-3.5 parts of magnesium stearate.

[0027] It is prepared from the following raw materials in parts by weight: 200 parts of amoxicillin, 8 parts of sodium carboxymethylcellulose, 1.25 parts of talcum powder and 2 parts of magnesium stearate.

[0028] The amoxicillin is amoxicillin heavy powder granules obtained by dry granulation, and the particle size of the amoxicillin heavy powder granules is less than 20 mesh.

[0029] 70%-98% of the amoxicillin heavy powder granules have a particle size of 20-80 mesh, and 2%-30% of the amoxicillin heavy powder granules have a particle size of less than 80 mesh.

[0030] The particle size range of 50%-70% amoxicillin heavy powder particles is between 20-50 mesh, the particle size range of 15-30% amoxicillin heavy powder particles is between ...

Embodiment 2

[0040] An amoxicillin capsule is made of the following raw materials in parts by weight: 200 g of amoxicillin, 5 g of sodium carboxymethylcellulose, 1 g of talc, and 0.5 g of magnesium stearate.

[0041] The particle size range of 50% amoxicillin heavy powder granules is between 20-50 mesh, the particle size range of 25% amoxicillin heavy powder granules is between 50-80 mesh, and the particle size range of 25% amoxicillin heavy powder granules is The particle size is less than 80 mesh.

[0042] A kind of preparation method of above-mentioned amoxicillin capsule, concrete steps are as follows:

[0043] (1) Mix amoxicillin and talc evenly;

[0044] (2) The mixture obtained in step (1) and the dry inert gas are injected into the ultrafine pulverizer together, and crushed by high-speed airflow, and the obtained particles are passed through 500 sieves;

[0045] (3) Mix the fine powder obtained in step (2) with sodium carboxymethylcellulose evenly, pass through a 20-mesh sieve, m...

Embodiment 3

[0051] An amoxicillin capsule is made of the following raw materials in parts by weight: 200 g of amoxicillin, 5.5 g of sodium carboxymethylcellulose, 1.05 g of talc, and 0.8 g of magnesium stearate.

[0052] 52% of amoxicillin heavy powder granules have a particle size range of 20-50 mesh, 26% of amoxicillin heavy powder granules have a particle size range of 50-80 mesh, and 22% of amoxicillin heavy powder granules The particle size is less than 80 mesh.

[0053] A kind of preparation method of above-mentioned amoxicillin capsule, concrete steps are as follows:

[0054] (1) Mix amoxicillin and talc evenly;

[0055] (2) The mixture obtained in step (1) and the dry inert gas are injected into the ultrafine pulverizer together, and crushed by high-speed airflow, and the obtained particles are passed through 500 sieves;

[0056] (3) Mix the fine powder obtained in step (2) with sodium carboxymethylcellulose evenly, pass through a 20-mesh sieve, make wet granules, dry, and then pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com