Method for utilizing flue gas low-temperature heat quantity for industrial furnace

An industrial furnace and flue gas technology, applied in air heaters, furnaces, waste heat treatment, etc., can solve problems such as high operating costs, complex processes, and unutilized heat, to improve thermal efficiency, increase temperature, and improve the average temperature field. The effect of heat intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

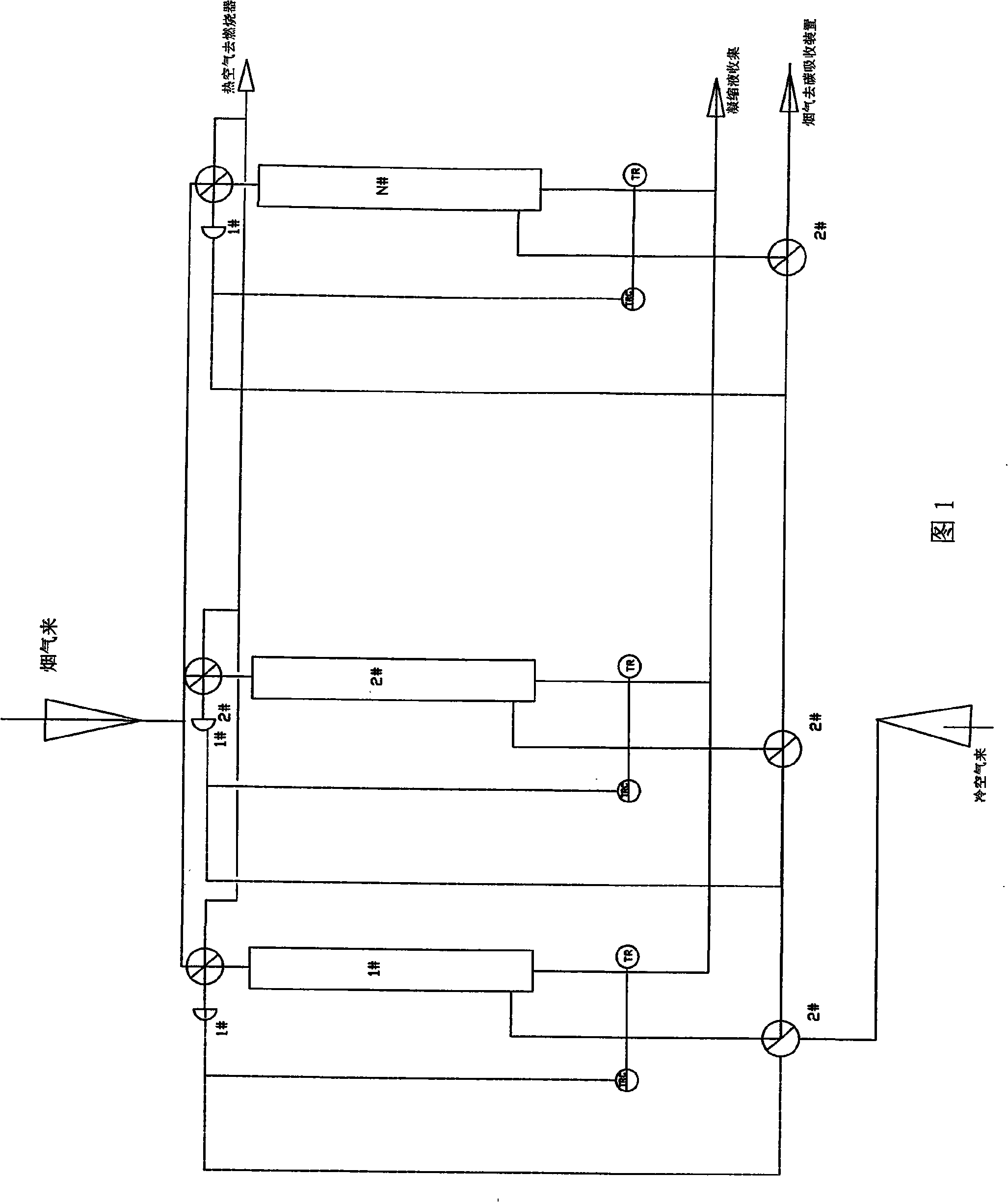

[0013] Referring to Fig. 1, the method for utilizing the low-temperature heat of industrial furnace flue gas according to the present invention is to use three or more groups of regenerative air preheaters connected in parallel, and the regenerative air preheaters are made of ceramic or glass-lined or The air preheater in which the ceramic matrix composite material is the wall and the ceramic regenerator is the heat transfer element, the method specifically includes the following process: the flue gas above the dew point from the convection section of the heating furnace flows to the first group of regenerative The 1# three-way valve of the air preheater enters the first group of regenerative air preheater through the 1# three-way valve, and the flue gas passes through the heat to the heat storage body of the first group of regenerative air preheater And cool down to below 70 ℃, through the 2# three-way valve of the first group of regenerative air preheater, it flows into the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com