Catalytic cracking method for preparing N-(3-dimethylamino propyl) methacrylamide

A technology of methacrylamide and dimethylaminopropyl, which is applied in the field of preparation of N-methacrylamide, which can solve the problem of high heat transfer temperature difference in catalytic cracking reactor, unstable operation of segregation system, and reduced utilization rate of public works To achieve the effect of maintaining the condensation temperature, stabilizing the drop rate of the material, and reducing the load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

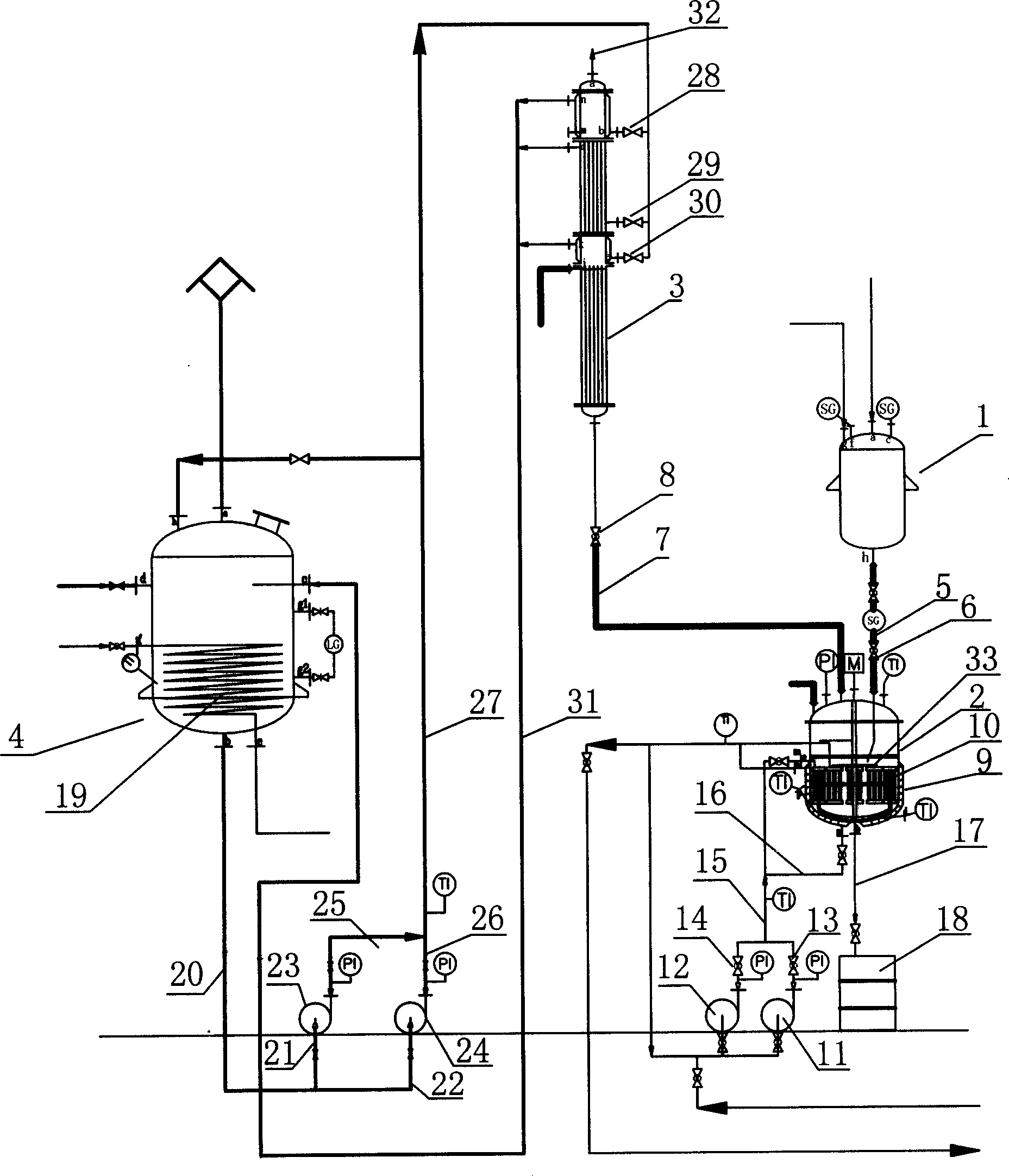

[0047] A kind of catalytic cracking method of preparing N-(3-dimethylaminopropyl) methacrylamide of embodiment two is basically the same as embodiment one, and its difference is: get intermediate material 20kg, catalyst calcium nitrate 0.4kg After mixing, put it into the reaction kettle 2, mix 1000kg of the intermediate material and 0.5kg of the catalyst, and then add it to the high-level dripping tank 1; keep the return temperature of the circulating hot water ≤ 103°C; the temperature difference between the inside and outside of the kettle is 20°C.

Embodiment 3

[0049] A kind of catalytic cracking method of preparing N-(3-dimethylaminopropyl) methacrylamide of embodiment three is basically the same as embodiment one, and its difference is: get intermediate material 20kg, catalyst calcium nitrate 0.8kg After mixing, put it into the reaction kettle 2, mix 1000kg of the intermediate material and 1kg of the catalyst calcium nitrate, and then add it to the high-level dropping tank 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com