Modeling and virtual simulating method for integrated coal gasification combined cycling air separating system

A technology of integrated coal gasification and combined cycle, applied in the direction of cold treatment separation, liquefaction, teaching model, etc., can solve the problems of complex operating characteristics of the system, difficult mathematical models, and high energy consumption of the air separation system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

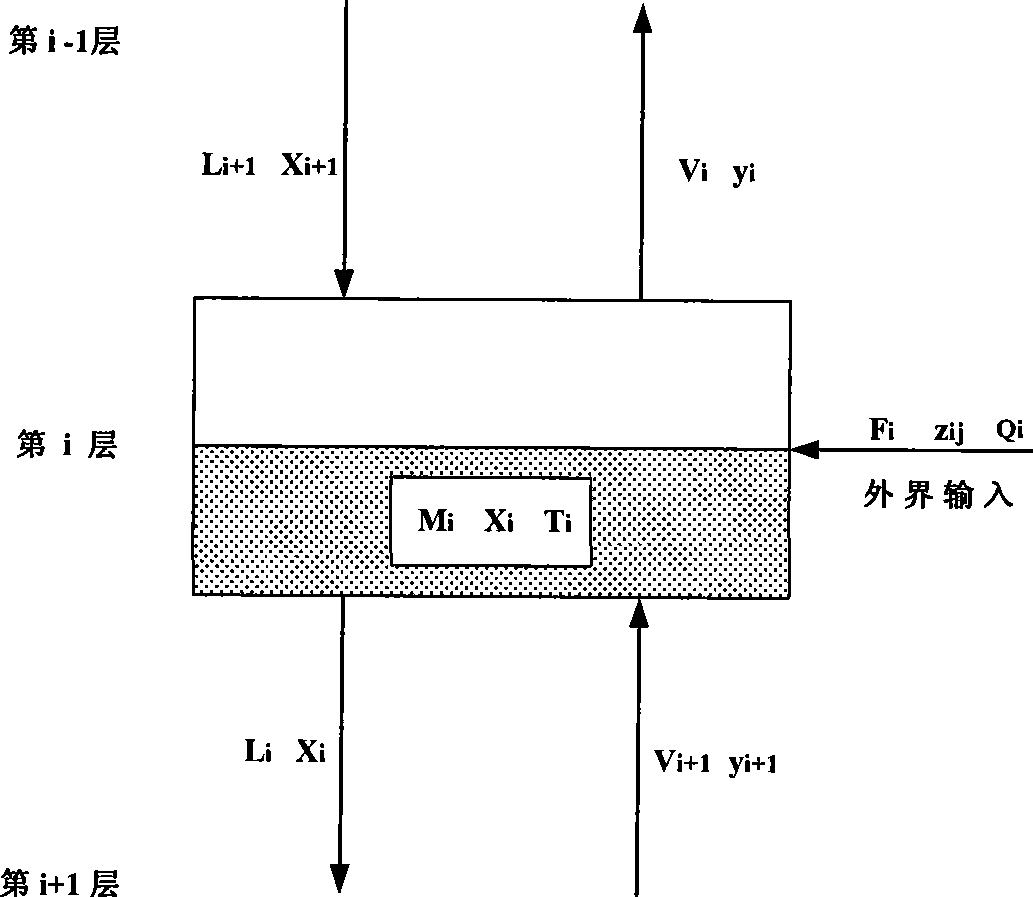

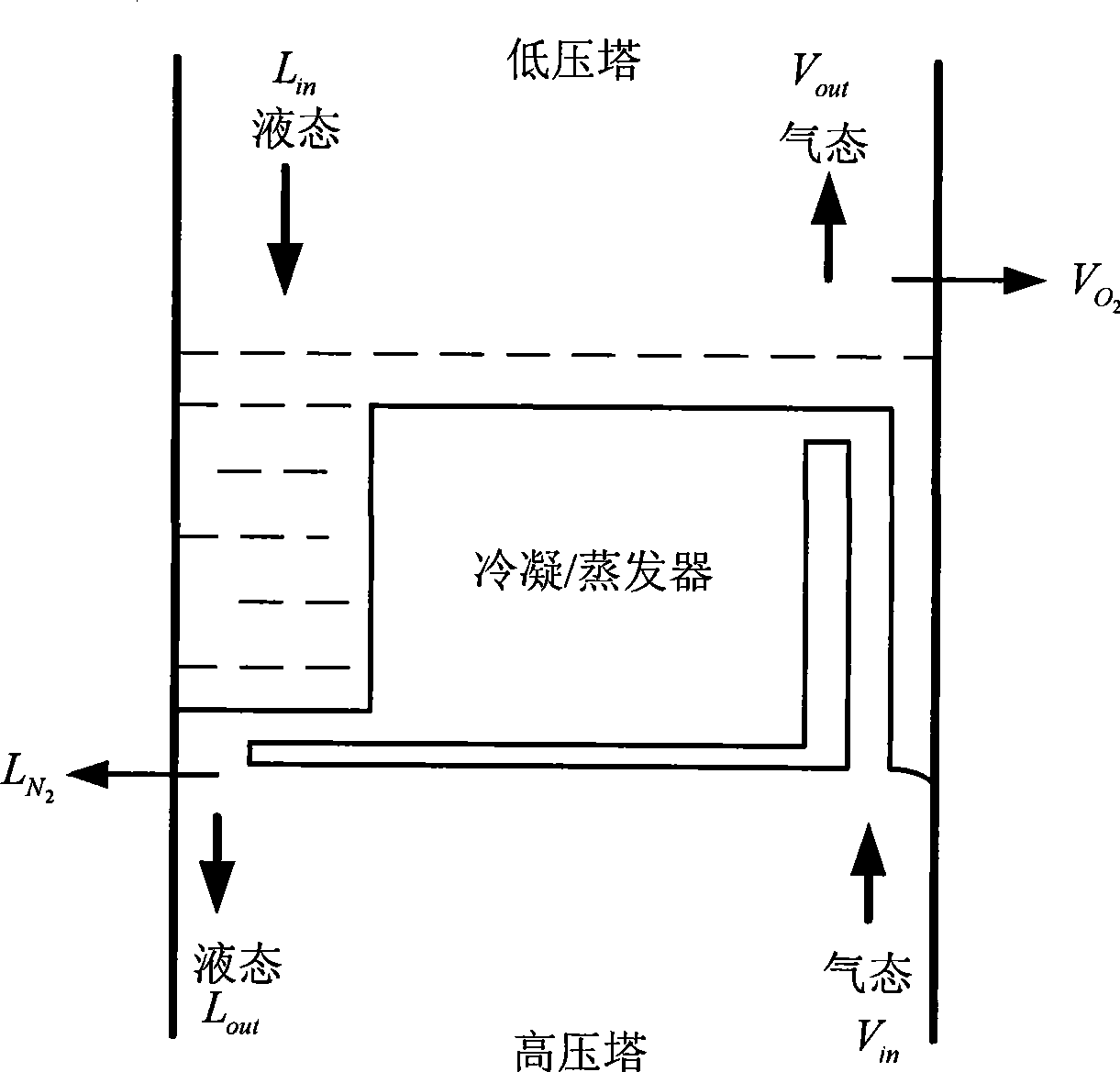

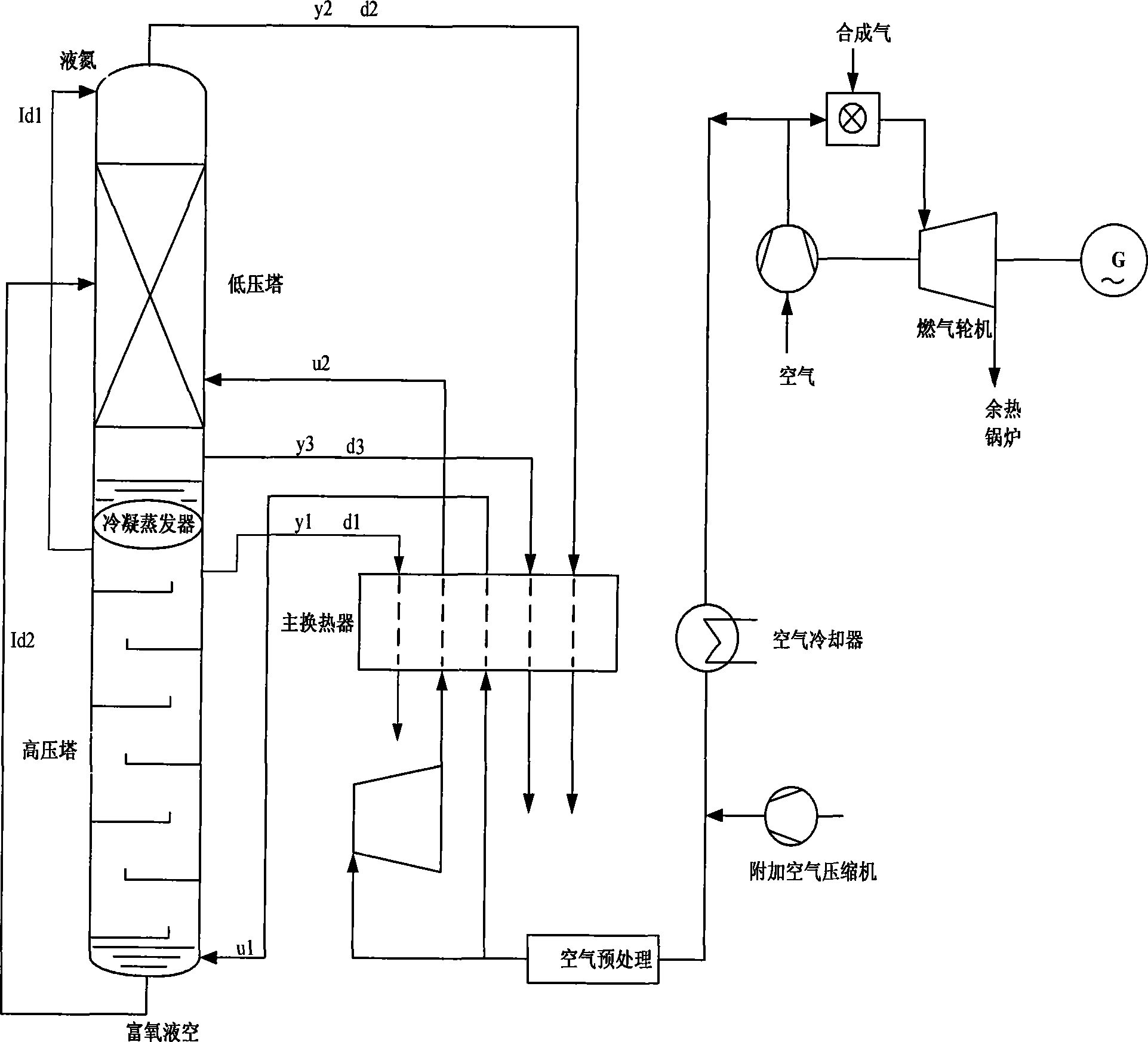

[0085] The modeling and virtual simulation method of the air separation system of IGCC power station is based on the total mass balance differential equation, component mass balance differential equation, energy balance differential equation, gas-liquid phase balance algebraic equation, molecular normalized algebraic equation and gas phase and liquid The method of combining algebraic equations of phase properties with the condensing-evaporator model connecting the upper tower and the lower tower constitutes an accurate mechanism model of the air separation system; and sets the input, output and disturbance variables of the system according to the model, and performs virtual simulation of the system . The main contents of the present invention can be divided into three aspects: one is to set the input, output and disturbance variables of the system on the basis of establishing an accurate mechanism model, so as to study the control characteristics of the system and lay the found...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com