Method for synthesis of zinc molybdate or alkali type zinc molybdate

A technology for synthesizing zinc molybdate and zinc molybdate, which is applied in chemical instruments and methods, molybdenum compounds, inorganic chemistry, etc., can solve the problems of difficult centrifugation, low product yield, and affecting product quality, and achieves environmental friendliness and synthetic The effect of simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

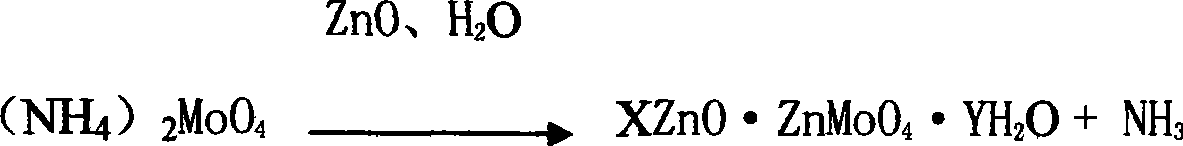

Method used

Image

Examples

Embodiment 1

[0017] Weigh 68g of industrial-grade ammonium heptamolybdate (also known as ammonium molybdate tetrahydrate) and put it into a flat-bottomed flask, add 350mL of water, heat to dissolve, and set aside.

Embodiment 2

[0019] Measure 50mL of 27% ammonia water into a flat-bottomed flask, add 65g of industrial grade ammonium tetramolybdate and 300mL of water, magnetically stir to dissolve, and set aside.

Embodiment 3

[0021] In the ammonium molybdate solution prepared in Example 1 or Example 2, add 32g of industrial grade ZnO (the molar ratio of Zn / Mo is 1:1) while magnetically stirring, and connect the water absorption device to the outlet of the flat-bottomed flask. Heat up to 50°C, react at constant temperature for 2 hours, centrifuge to obtain a white precipitate, and keep the mother liquor for future use. Put the white precipitate into an oven, control the temperature at 110° C., and dry it for 5 hours to obtain a white powder weighing 90.5 g. The white powder is ZnMoO 4 2H 2 O, content 99.1%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com