Purification assembly technique of nitrous oxides in air

A nitrogen oxide, combined process technology, applied in the field of air purification and atmospheric environmental protection, can solve the problems of low absorption efficiency, secondary pollution, high investment and operating costs, reduce raw material costs, create economic benefits, and low operating costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

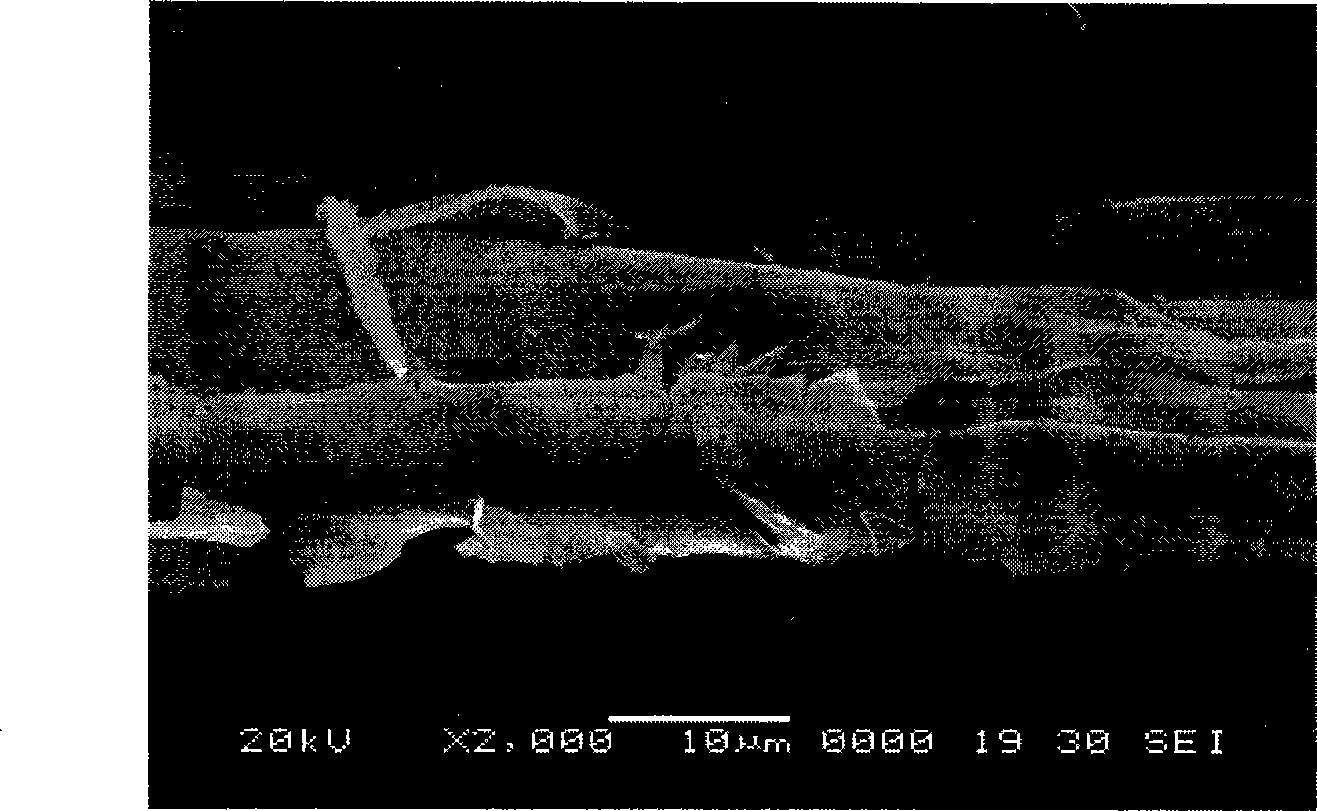

[0034] Cedar wood chips (such as figure 2 Shown) sieve to ensure that the size is controlled below 2mm, take 20g Chinese fir sawdust, wash in water, and soak in 5% KOH activation solution for 48h, control the oven temperature at 115°C to 120°C, and dry to obtain the Chinese fir sawdust filler.

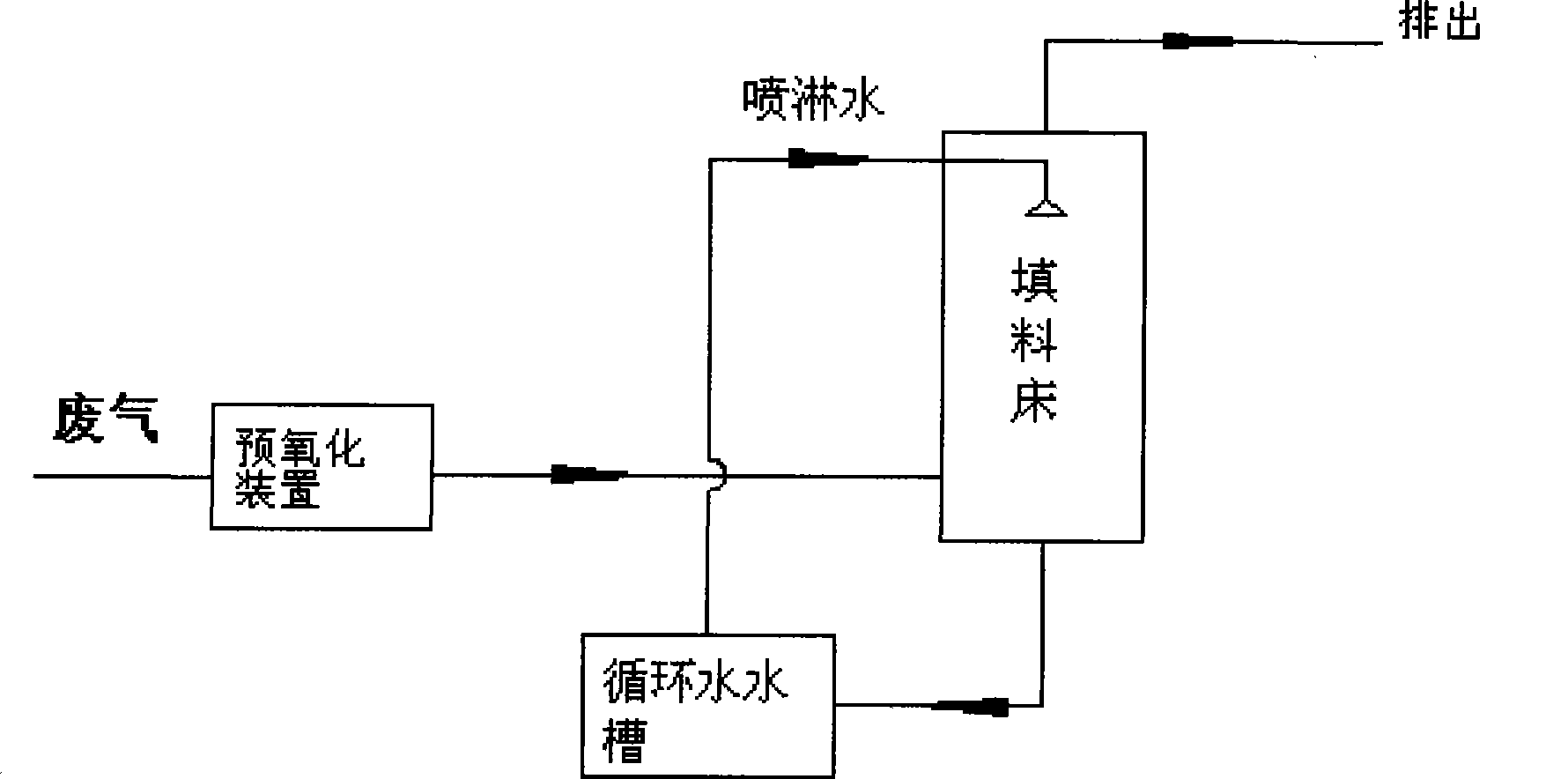

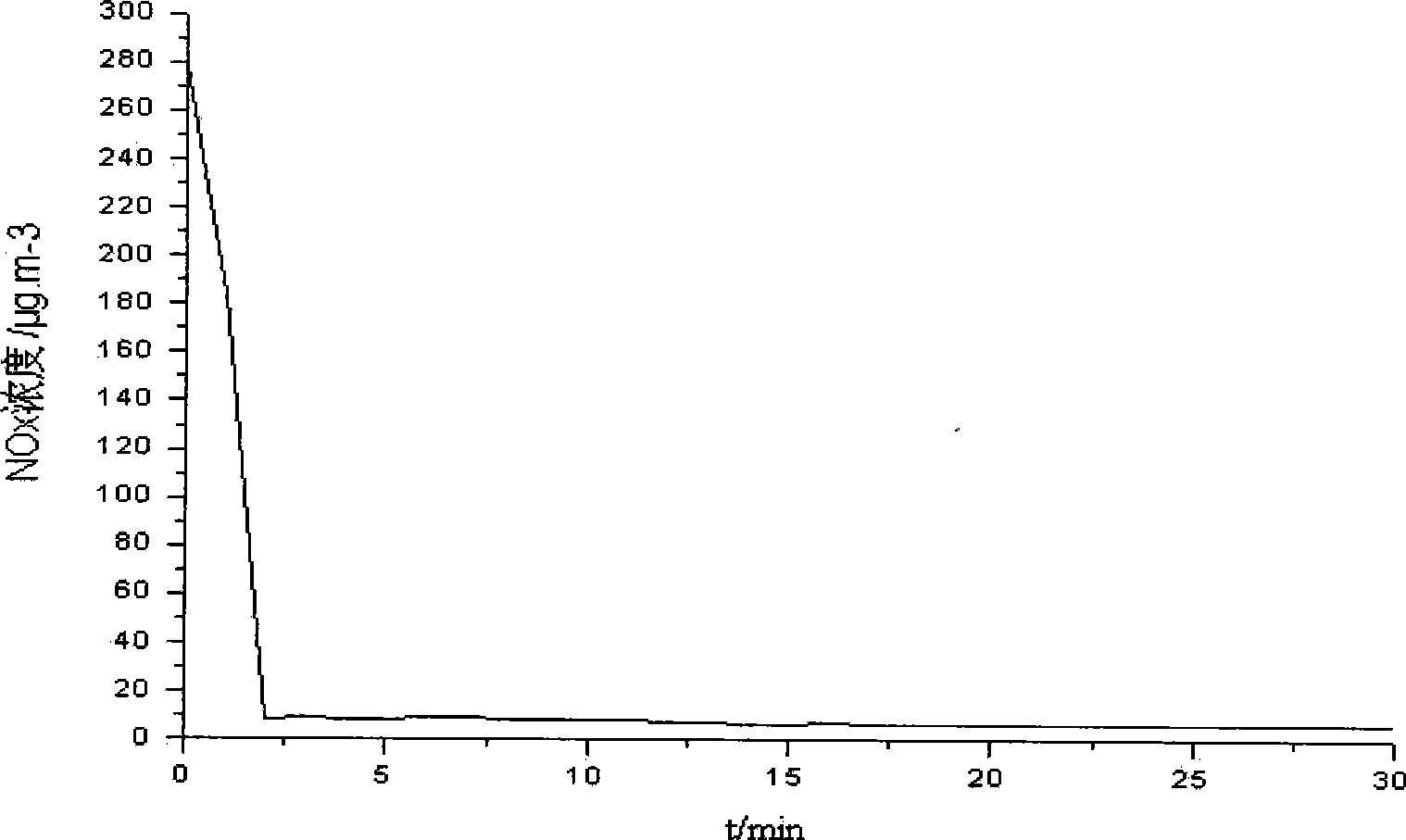

[0035] Get 8g of Chinese fir sawdust filler and pack it in the filler column, connect the pipeline, check the airtightness of the device, and it will contain nitrogen oxides 135ppb (0.3mg / m 3 ) of the gas to be treated first passes through the pre-oxidation treatment device, and then passes through the fir sawdust packing bed from bottom to top. , The intermittent spray is controlled by the temperature and humidity or the time using the solenoid valve, and the spray water is recycled. The treated gas is discharged from the nitrogen oxide detector at the top of the packed bed. image 3 It is a dynamic effect diagram of the purification of nitrogen oxides by fir sawdust fillers. The p...

Embodiment 2

[0037] Sieve the larch sawdust to ensure that the particle size is controlled below 2mm, wash 15g of larch sawdust in water, and soak in 5% NaOH activation solution for 24 hours, control the oven temperature at 105°C to 110°C, and dry to obtain Larch sawdust filler.

[0038] Take 8g of larch sawdust filler and fill it in the filler column, connect the pipeline, check the airtightness of the device, and it will contain nitrogen oxides 135ppb (0.3mg / m 3 ) of the gas to be treated first passes through the pre-oxidation treatment device, and then passes through the larch sawdust packing bed from bottom to top. min, the intermittent spray is controlled by the temperature and humidity or time using the solenoid valve, and the spray collection liquid is recycled. The treated gas is discharged from the nitrogen oxide detector at the top of the packed bed. Figure 4 It is a dynamic effect diagram of purifying nitrogen oxides by larch sawdust fillers. The purification efficiency of la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com