Method for directly drilling blind hole by laser using carbon dioxide

A direct laser and carbon dioxide technology, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of difficult control of the process, application of copper layer micro-etching, high cost, etc., to achieve low cost and reduce the hanging copper at the hole , the effect of exchanging sufficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

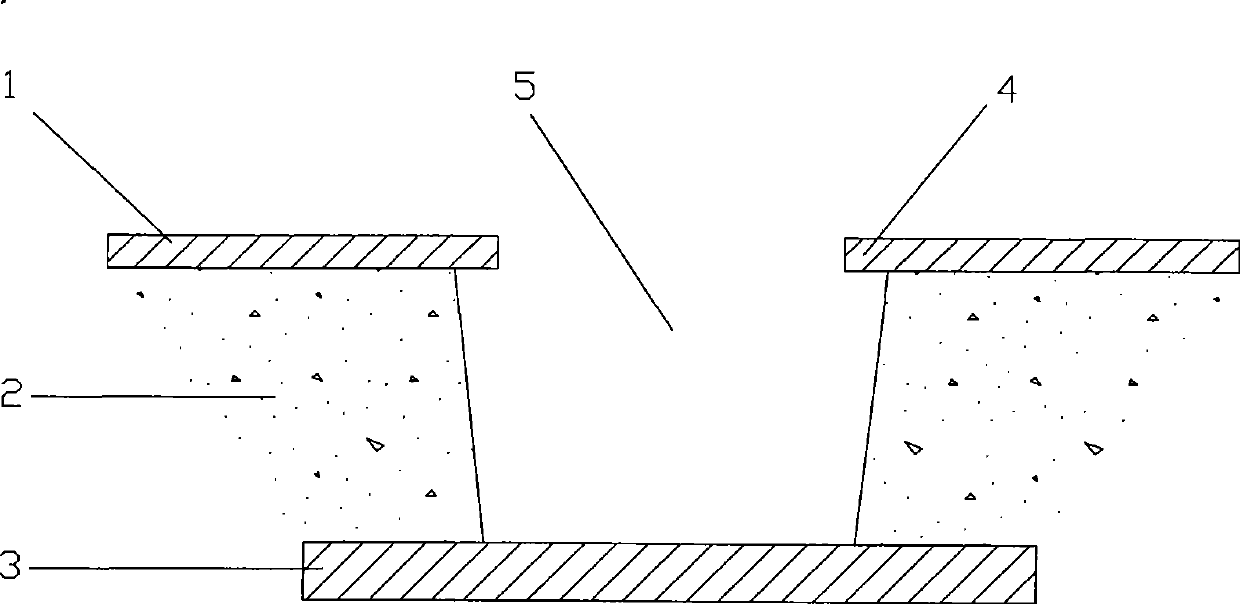

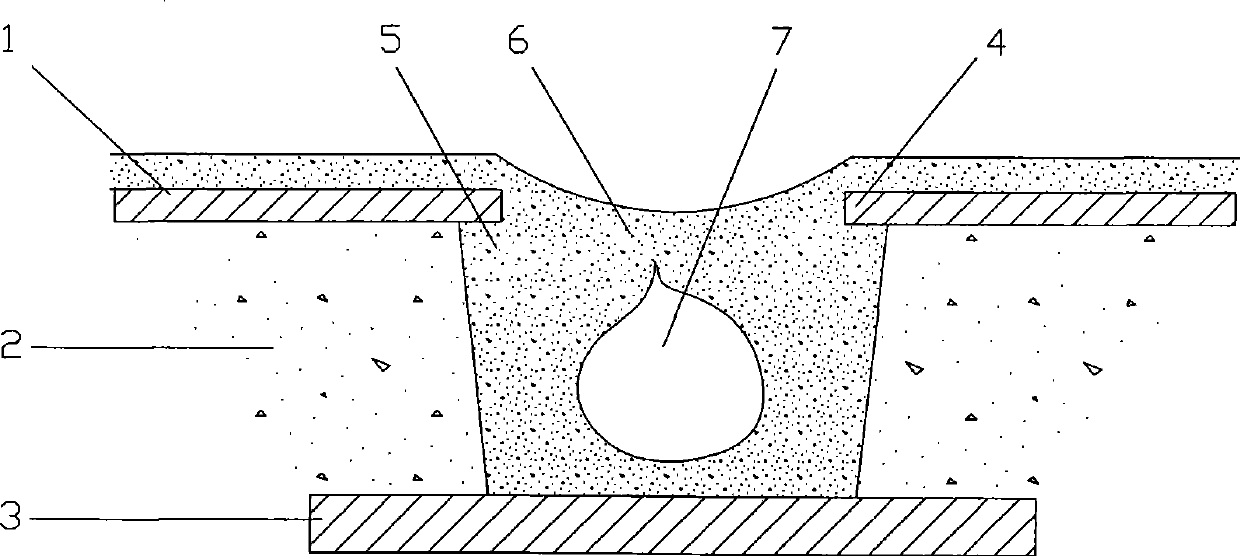

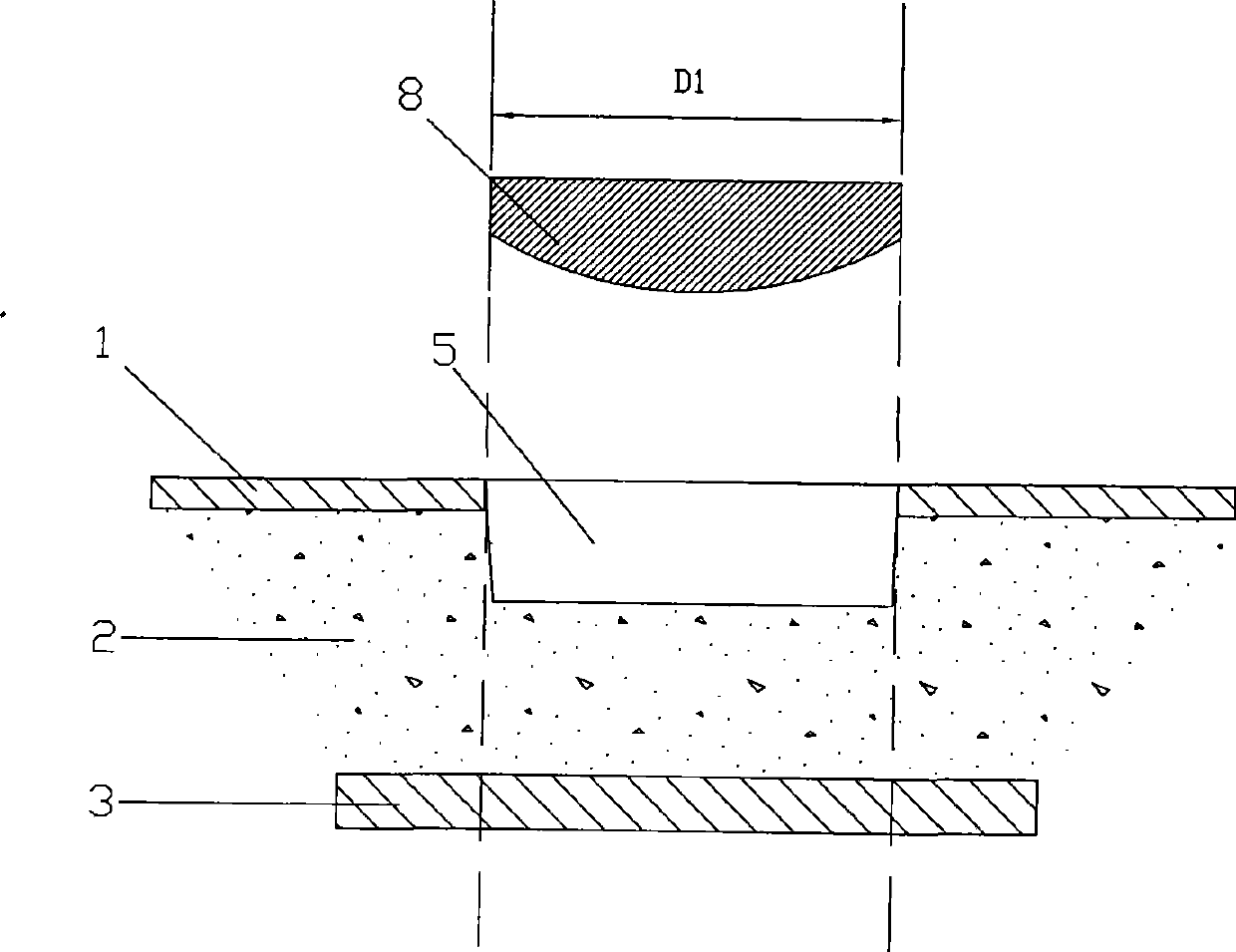

[0026] see Figure 4a , Figure 4b , the concrete steps of the inventive method are as follows:

[0027] Step 1: Laminate multi-layer printed boards (the thickness of the surface copper foil is 17-18 μm);

[0028] Step 2: Complete the copper foil thinning treatment (the thickness of the copper foil after thinning is 5-6 μm);

[0029] Step 3: Use chemical potion to oxidize the surface of the copper foil to improve the absorption rate of the copper foil to the laser;

[0030] Step 4: First select a larger laser aperture 18. The laser pulse spot size corresponding to the aperture 18 is D3. For example, to process a 125μm laser blind hole, the laser spot size D3 is about 125μm. Use 1 pulse with a pulse time of 16μs to complete Processing of copper layer 1 of the whole board;

[0031] Step 5: Select a smaller laser aperture 20. The laser pulse spot size corresponding to aperture 20 is D4. For example, to process a 125μm laser blind hole, the laser spot size D4 is about 80μm. Us...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com