Nonaqueous-electrolyte battery

一种非水电解液、电池的技术,应用在非水电解质、电池电极、二次电池等方向,能够解决电池大电流特性、自放电特性电池特性劣化等问题,达到良好电池特性、提高安全性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0138]

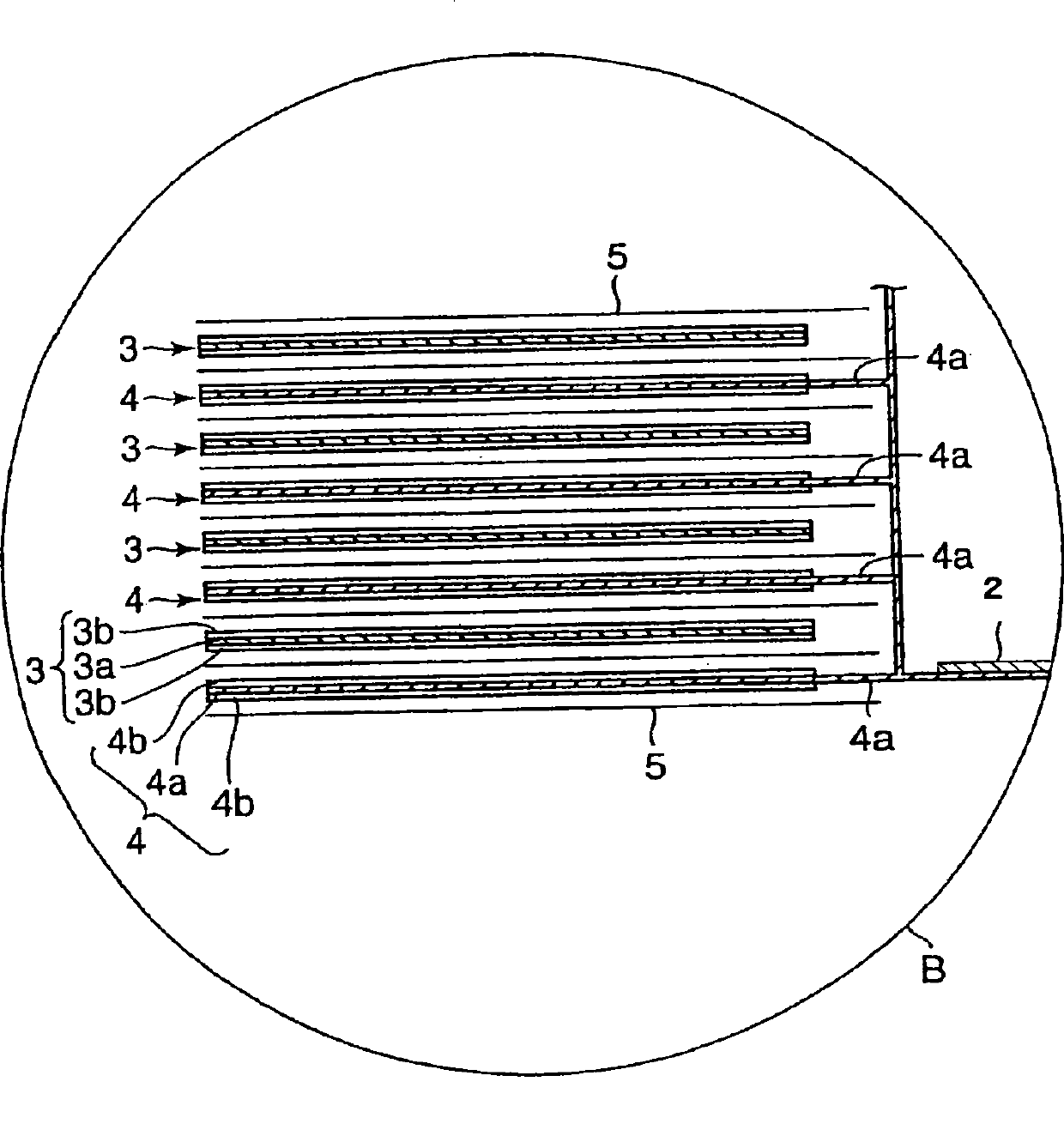

[0139] First, lithium manganese oxide (LiMn 2 o 4 ) powder 90% by weight, 3% by weight of acetylene black as a conductive agent, 3% by weight of graphite, and 4% by weight of polyvinylidene fluoride (PVdF) are added to N-methylpyrrolidone (NMP) and mixed to make a slurry, This slurry was coated on both sides of a current collector made of aluminum foil with a thickness of 15 μm, dried, and punched to produce an electrode with a density of 3.0 g / cm 3 positive pole.

[0140]

[0141] As the negative electrode active material, prepared a 2 / g, Li intercalation potential is 1.55V (vs.Li / Li + ) spinel lithium titanate (Li 4 Ti 5 o 12 )powder. The particle size measurement of negative electrode active material is to use laser diffraction type distribution measuring device (Shimadzu SALD-300), utilize following method to measure, that is, at first, add about 0.1g sample, surfactant and 1~ After fully stirring 2 mL of distilled water, pour it into the stirring wat...

Embodiment 5、13

[0152] A nonaqueous electrolyte secondary battery was fabricated in the same manner as in Examples 4 and 10 except that 1,4-diisocyanate butane was added instead of 1,6-diisocyanate hexane as the nonaqueous electrolyte solution.

Embodiment 14~18

[0154] In addition to adding 1-isocyanate ethane, 2-isocyanate propane, 1-isocyanate hexane, 1-isocyanate butane, and 3-isocyanate-1-propane instead of 1,6-diisocyanate hexane as a non-aqueous electrolyte, A nonaqueous electrolyte secondary battery was produced in the same manner as in Example 10.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electric potential / voltage | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com