Use method of modified bentonite by lithiation in casting wet type clay sand

A technology of wet clay sand and bentonite, which is used in foundry molding equipment, molds, cores, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

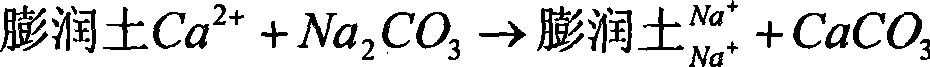

Method used

Image

Examples

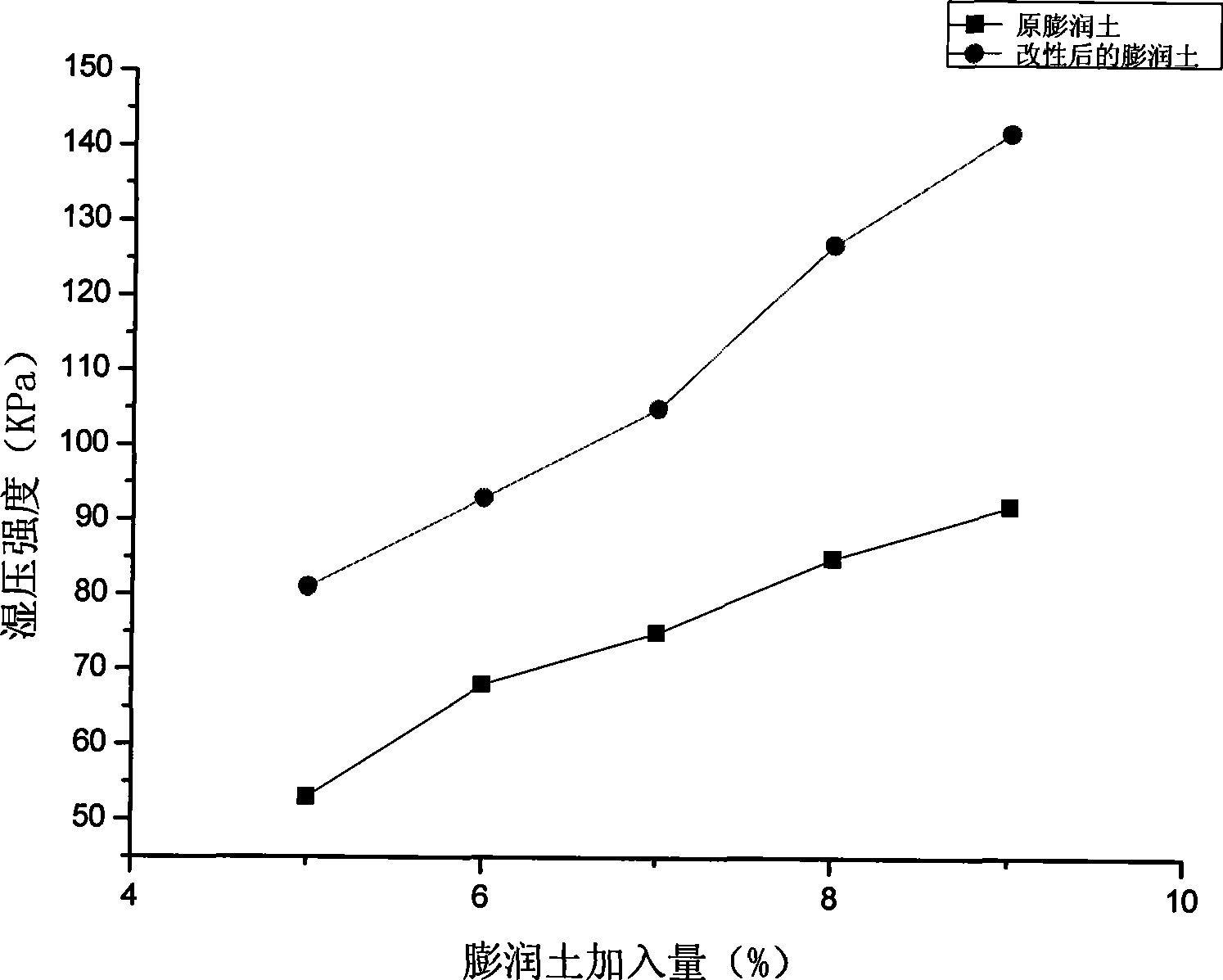

Embodiment 1

[0016] Old sand (after old sand treatment, such as crushing, demagnetization, screening, dust removal, cooling, etc., particle size 15Q(H) (○-□) 70% (wt), new sand (particle size 15Q(H), □—○) 30% (wt), according to the practice of the foundry industry, except sand, the weight percentage of the remaining components refers to the weight percentage of the component relative to 100 parts of sand, lithiated bentonite 8% (wt) (based on 100 parts of sand weight) , coal powder (casting coal powder) 2% (wt) (in 100 parts of sand weight), moisture 5 ~ 6% (wt) (in 100 parts of sand weight) (adding when molding sand is wet mixed). The wheel type sand mixer is used for mixing. First, dry mix new sand, old sand, coal powder, and lithiated bentonite for 2 minutes, then add water and wet mix for 10 minutes. The wet compressive strength of the molding sand is 156KPa, and the air permeability is 110.

Embodiment 2

[0018] Old sand (after old sand treatment, such as crushing, demagnetization, screening, dust removal, cooling, etc., particle size 15Q(H) (○-□) 95% (wt), new sand (particle size 15Q(H), □—○) 5% (wt), lithiated bentonite 9% (wt) (based on 100 parts of sand weight), coal powder (casting coal powder) 4% (wt) (based on 100 parts of sand weight), moisture 5-6% (wt) (based on 100 parts of sand weight) (adding when the molding sand is wet-mixed). Carry out mixing with a common roller type sand mixer, first dry-mix new sand, old sand, coal powder, lithiated bentonite for 2 minutes, and then Add water and wet mix for 10 minutes.The wet compressive strength of the molding sand is 148KPa, and the air permeability is 100.

Embodiment 3

[0020] Old sand (after old sand treatment, such as crushing, demagnetization, screening, dust removal, cooling, etc., particle size 15Q(H) (○-□) 50% (wt), new sand (particle size 15Q(H), □—○) 50% (wt), lithiated bentonite 10% (wt) (based on 100 parts of sand weight), coal powder (casting coal powder) 4% (wt) (based on 100 parts of sand weight), moisture 5-6% (wt) (based on 100 parts of sand weight) (adding when the molding sand is wet-mixed). Carry out mixing with a common roller type sand mixer, first dry-mix new sand, old sand, coal powder, lithiated bentonite for 2 minutes, and then Add water and wet mix for 10 minutes.The wet compressive strength of the molding sand is 160KPa, and the air permeability is 100.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com