Low temperature oil-contaminated water processing method

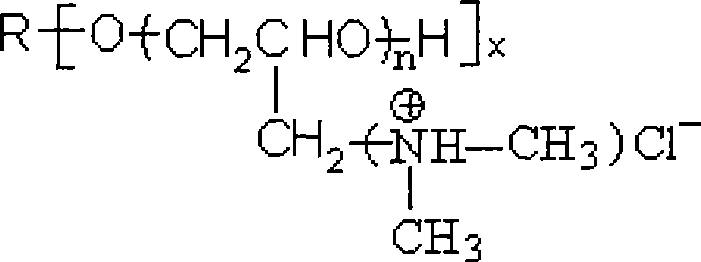

A treatment method and technology for oily sewage, applied in flotation water/sewage treatment, flocculation/sedimentation water/sewage treatment, etc., can solve the problems of thermal imbalance of branch lines, high system energy consumption, backward process, etc., and achieve uniform distribution , The effect of high processing efficiency and small dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

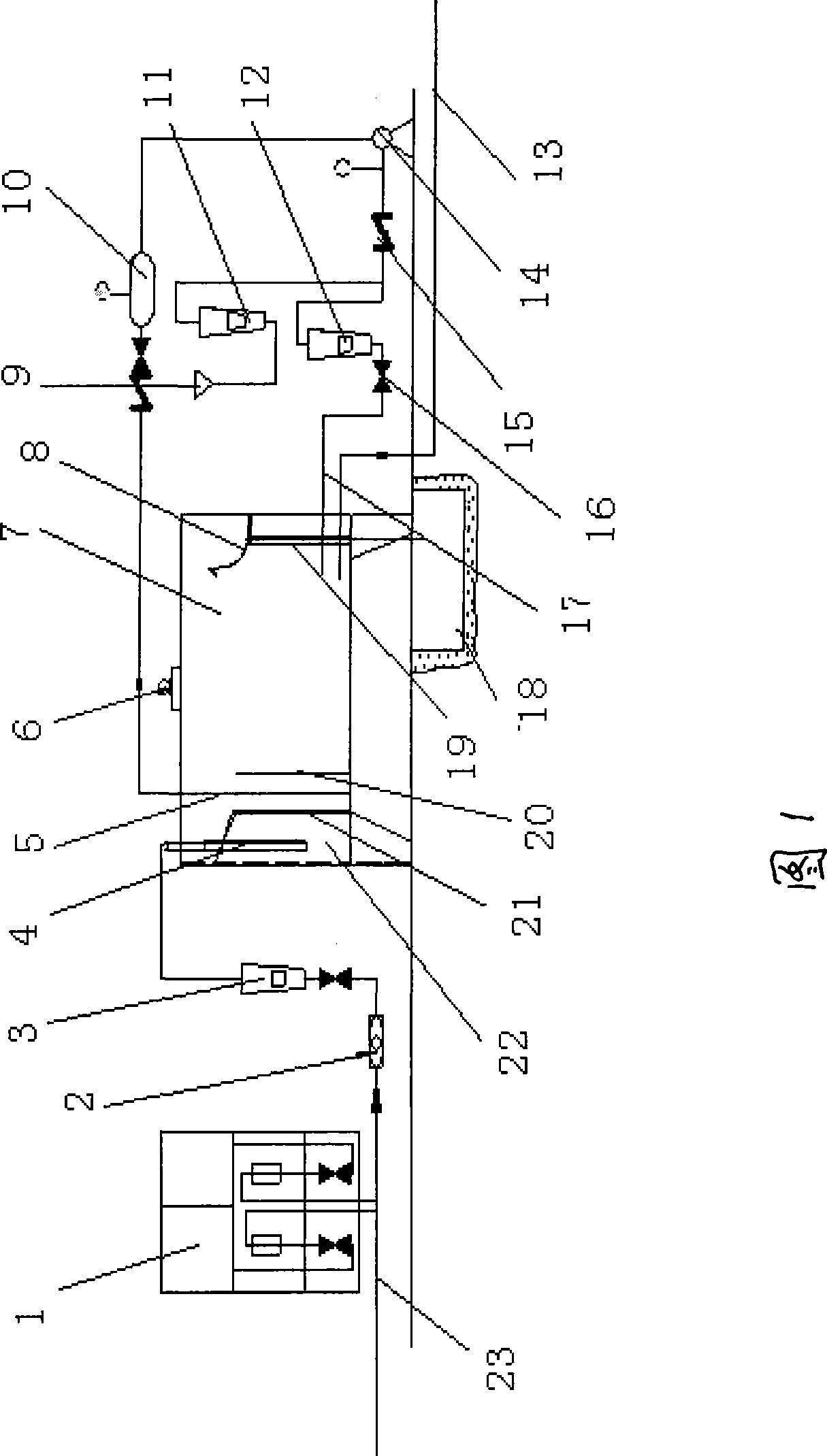

Method used

Image

Examples

Embodiment

[0029] The invention is given by the following examples.

example 1

[0030] Example 1. The temperature of incoming oily sewage is 29°C, and the concentration of flotation agent is 100 mg / L. The results after treatment by air flotation device are shown in Table 1.

[0031] Table 1. Air flotation results under the condition that the dosing concentration of flotation agent is 100mg / L

[0032]

example 2

[0033] Example 2. The temperature of incoming oily sewage is 29°C, and the concentration of flotation agent is 75 mg / L. The results after treatment by air flotation device are shown in Table 2.

[0034] Table 2. Air flotation results under the condition that the dosing concentration of flotation agent is 75mg / L

[0035]

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap