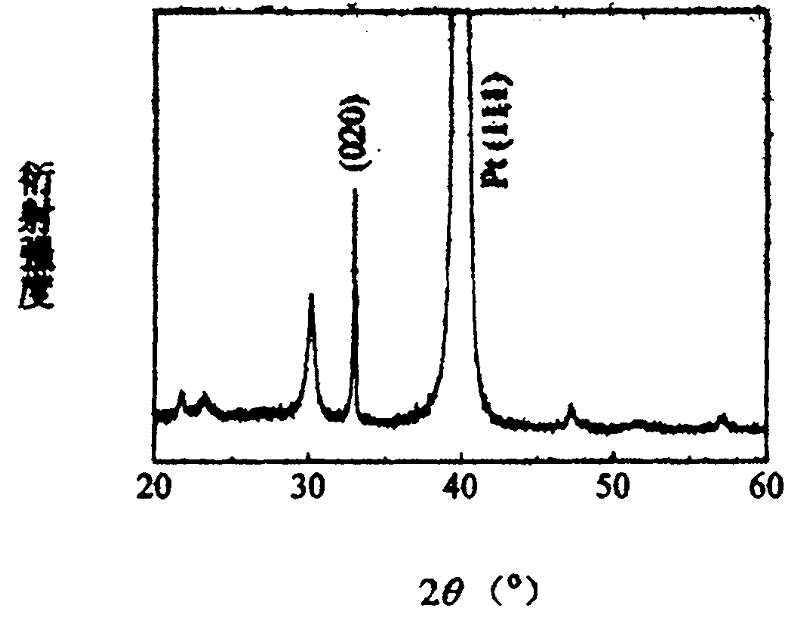

Preparation of (020) preferred orientation bismuth titanate film

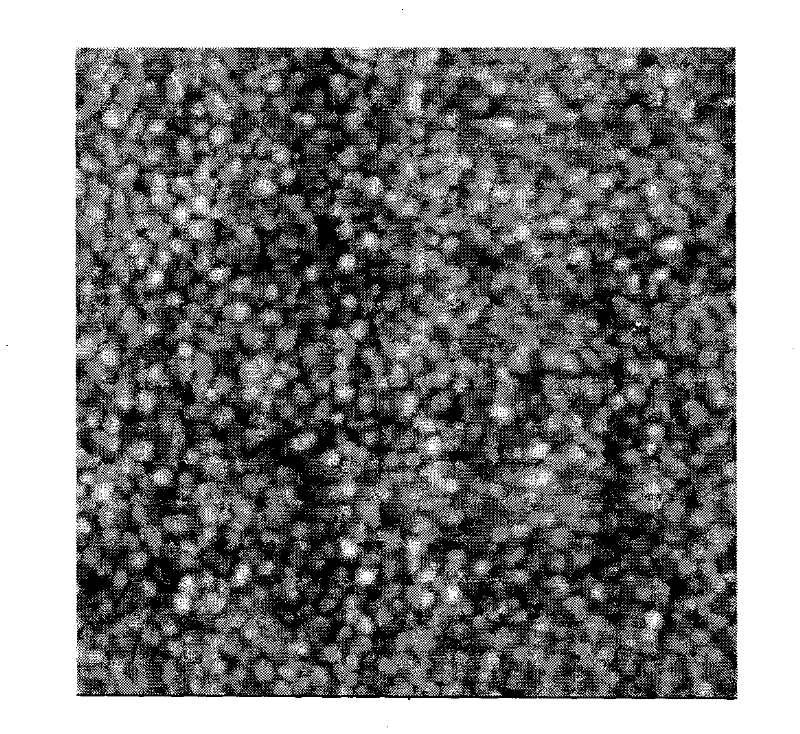

A technology of preferred orientation and bismuth titanate, which is applied in the field of thin film materials, can solve the problems of difficult preferred orientation of thin films and poor ferroelectric properties, and achieve the effects of superior ferroelectric properties, small surface roughness and high film density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0008] Specific Embodiment 1: The steps of the method for preparing the preferred orientation bismuth titanate film in this embodiment (020) are as follows: 1. Mix the mixture of lanthanum nitrate and bismuth hyponitrate with acetic acid in a molar ratio of 1:10 to 80, and then slowly add mass Percentage concentration is 99.0%~99.8% ethylene glycol solution, makes the mol ratio of lanthanum ion and bismuth ion summation and ethylene glycol in the solution be 1: 5~18, stirs at room temperature 8~12min, obtains solution A; Two, will Slowly add an ethylene glycol solution with a mass percent concentration of 99.0% to 99.8% into tetrabutyl titanate so that the molar ratio of bismuth ions to ethylene glycol in the solution is 1:5 to 18, and stir at room temperature for 8 to 12 minutes to obtain a solution B; 3. Mix solution A and solution B, and stir at room temperature for 20-40 minutes to obtain Bi 4-x La x Ti 3 o 12 Sol; four, the Pt / Ti / SiO 2 / Si substrates were ultrasonical...

specific Embodiment approach 2

[0010] Specific embodiment two: the difference between this embodiment and specific embodiment one is that in step one, the mixture of lanthanum nitrate and bismuth subnitrate is mixed with acetic acid in a molar ratio of 1:40, and then slowly add ethylene glycol with a mass percentage concentration of 99.5%. Alcohol solution, so that the molar ratio of the sum of lanthanum ions and bismuth ions in the solution to ethylene glycol is 1:10, and stirred at room temperature for 10 min. Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0011] Specific embodiment three: the difference between this embodiment and specific embodiment one is that in step two, the ethylene glycol solution with a mass percentage concentration of 99.5% is slowly added in tetrabutyl titanate, so that the bismuth ion and ethylene glycol in the solution The molar ratio was 1:10, and stirred at room temperature for 10 min. Other steps and parameters are the same as those in Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com