Passivating treatment solution for surface of zinc or zinc alloy and passivation treatment method

A passivation treatment, zinc alloy technology, applied in the direction of metal material coating process, etc., can solve the problems of poor anti-corrosion effect and low passivation efficiency, and achieve the effect of reducing surface resistance, fast passivation and reducing hidden dangers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

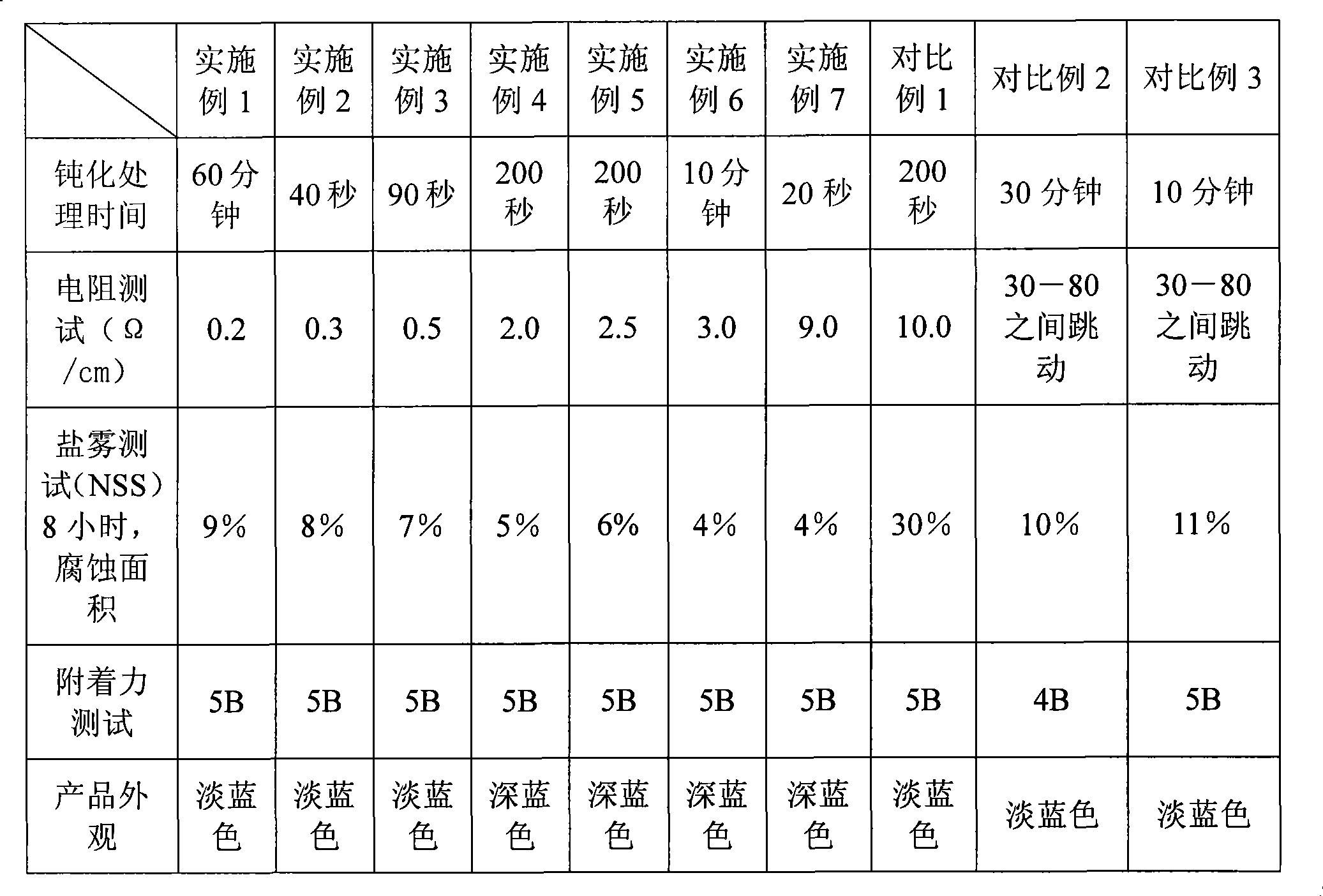

Examples

preparation example Construction

[0017] The passivation treatment solution can be prepared according to conventional preparation methods, for example, water-soluble yttrium salt, oxidant, complexing agent and soluble metavanadate are added to water and mixed uniformly, then, the pH of the passivation treatment solution The value is adjusted to 2.0-5.0, preferably 2.5-4, more preferably 3.0-3.5. The amount of each substance is such that in the prepared passivation treatment solution, the content of the water-soluble yttrium salt is 0.01-0.3 mole / liter in terms of yttrium, preferably 0.02-0.1 mole / liter, more preferably 0.05-0.06 mole / liter liter; the content of the oxidizing agent is 0.5-50 g / l, preferably 10-30 g / l, more preferably 15-25 g / l; the content of the complexing agent is 1-10 g / l, preferably 1-2 g / L, more preferably 1.5-1.8 g / L; the content of soluble metavanadate is 0.1-3 g / L, preferably 0.5-2 g / L, more preferably 0.8-1.5 g / L Lift.

[0018] The method for passivating the surface of zinc or zinc a...

Embodiment 1

[0035] Preparation of passivation treatment solution: Weigh 3 grams of yttrium nitrate and 1 gram of trisodium EDTA into a 1-liter beaker, add distilled water and stir until the solids are completely dissolved, then add 0.5 grams of hydrogen peroxide dropwise with a pipette, stir well, weigh and Add 0.5 g of ammonium metavanadate, and finally add distilled water to 1 liter and adjust the pH value to 2.0 with 0.1 mol / liter sodium carbonate solution.

[0036] Passivation treatment method: Take the die-cast zinc alloy product ZA-8, and degrease it through a degreasing solution (NaOH: 5 g / L; Na2CO3: 10 g / L; Na3PO4: 5 g / L; Na2B4O7: 1 g / L) (temperature: 55°C, time: 5 minutes), wash with pure water for 20 seconds; use an activator (fluorosilicic acid: 1 ml / liter; fatty alcohol polyoxyethylene ether (AEO-9): 0.5 g / liter) to degrease the product Conduct activation treatment, activate at room temperature for 3 minutes, wash with pure water for 20 seconds, put the zinc alloy product into...

Embodiment 2

[0038] This embodiment is used to illustrate the passivation treatment solution of the present invention and the passivation treatment method using the passivation treatment solution.

[0039] Preparation of passivation treatment solution: Pour 5 grams of yttrium nitrate and 1.0 grams of sodium citrate into a 1-liter beaker, add distilled water and stir until the solids are completely dissolved, then add 10 grams of hydrogen peroxide and 0.5 grams of ammonium metavanadate and stir well, and finally add Distill water to 1 L and adjust pH to 4.5 with 0.1 mol / L sodium carbonate solution.

[0040]Passivation treatment method: Take ZA-8, a die-cast zinc alloy product, and pass through a degreasing solution (NaOH: 5 g / L; NaOH: 5 g / L; 2 CO 3 : 10 g / L; Na 3 PO 4 : 15 g / L; Na 2 B 4 o 7 : 3 g / L) degreasing (temperature: 55°C, time: 5 minutes), washed with pure water for 3 minutes; then put the zinc alloy product into the passivation treatment solution prepared above for passivatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com