Green passivating agent for metal doors and windows

A technology of metal doors and windows and passivating agents, applied in organic chemistry, chemical instruments and methods, preparation of organic compounds, etc., can solve problems such as pollution and secondary pollution of the environment, achieve high use value, reduce personnel and the environment Hazard, effect of corrosion resistance reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

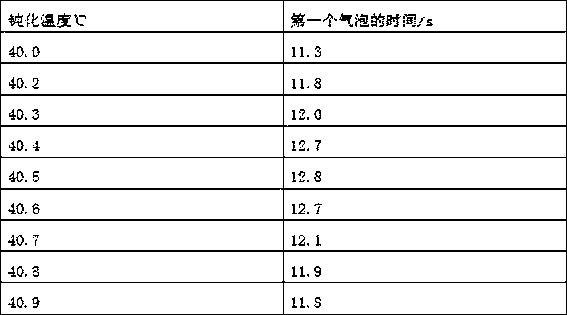

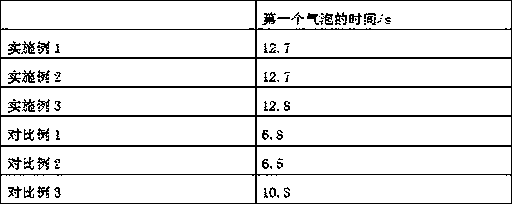

Examples

Embodiment 1

[0021] A green passivating agent for metal doors and windows, the green passivating agent contains 2-hydroxyl-3-butene-1-amine hydrochloride.

[0022] Further, the preparation method of the 2-hydroxy-3-butene-1-amine hydrochloride is:

[0023] (1) Add acrolein, trimethylsilyl cyanide and lithium perchlorate trihydrate successively in the reaction kettle, the molar ratio of acrolein, trimethylsilyl cyanide and lithium perchlorate trihydrate is 1:1.8:1.2, heat to 80°C, stirred for 2 hours at a speed of 150r / min, then added ethyl acetate with 6 times the mass of acrolein, stirred at a speed of 150r / min for 20min, and then filtered to obtain a filtrate, which was subjected to selective evaporation and drying. get intermediates;

[0024] (2) Add acetone 5 times its mass and lithium aluminum tetrahydrohydride 1.5 times its mass to the intermediate obtained above, heat to 70°C, stir at 150r / min for 2 hours, and then add 5% acetone mass Sodium sulfate and ethyl ether with 80% aceton...

Embodiment 2

[0033] A green passivating agent for metal doors and windows, the green passivating agent contains 2-hydroxyl-3-butene-1-amine hydrochloride.

[0034] Further, the preparation method of the 2-hydroxy-3-butene-1-amine hydrochloride is:

[0035] (1) Add acrolein, trimethylsilyl cyanide and lithium perchlorate trihydrate successively in the reaction kettle, the molar ratio of acrolein, trimethylsilyl cyanide and lithium perchlorate trihydrate is 1:1.8:1.2, heat to 80°C, stirred for 2 hours at a speed of 150r / min, then added ethyl acetate with 6 times the mass of acrolein, stirred at a speed of 150r / min for 20min, and then filtered to obtain a filtrate, which was subjected to selective evaporation and drying. get intermediates;

[0036] (2) Add acetone 5 times its mass and lithium aluminum tetrahydrohydride 1.5 times its mass to the intermediate obtained above, heat to 70°C, stir at 150r / min for 2 hours, and then add 5% acetone mass Sodium sulfate and ethyl ether with 80% aceton...

Embodiment 3

[0045] A green passivating agent for metal doors and windows, the green passivating agent contains 2-hydroxyl-3-butene-1-amine hydrochloride.

[0046] Further, the preparation method of the 2-hydroxy-3-butene-1-amine hydrochloride is:

[0047] (1) Add acrolein, trimethylsilyl cyanide and lithium perchlorate trihydrate successively in the reaction kettle, the molar ratio of acrolein, trimethylsilyl cyanide and lithium perchlorate trihydrate is 1:1.8:1.2, heat to 80°C, stirred for 2 hours at a speed of 150r / min, then added ethyl acetate with 6 times the mass of acrolein, stirred at a speed of 150r / min for 20min, and then filtered to obtain a filtrate, which was subjected to selective evaporation and drying. get intermediates;

[0048] (2) Add acetone 5 times its mass and lithium aluminum tetrahydrohydride 1.5 times its mass to the intermediate obtained above, heat to 70°C, stir at 150r / min for 2 hours, and then add 5% acetone mass Sodium sulfate and ethyl ether with 80% aceton...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com