Vacuum sputtering and electrophoresis combined coating technology for processing micro-arc oxidation workpiece

A micro-arc oxidation and vacuum sputtering technology, applied in vacuum evaporation coating, metal material coating process, anodizing and other directions, can solve the problems of high energy consumption, no metal texture, loss of ceramic effect, etc., and achieve good application Foreground, strong metallic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

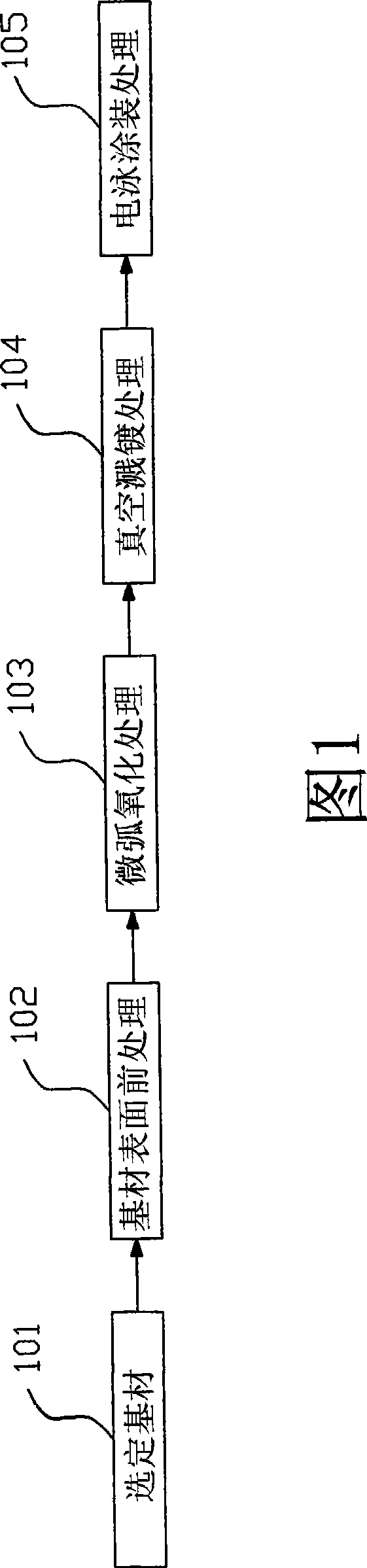

[0018] Please refer to FIG. 1, which is a process flow diagram of a preferred embodiment of the process of processing a micro-arc oxidation workpiece by vacuum sputtering combined with electrophoretic coating technology of the present invention.

[0019] As shown in Figure 1, the process flow is:

[0020] Step 101, a substrate is selected. The substrate can be a passivable metal such as Al, Mg, Ti, or an alloy thereof. In this embodiment, an aluminum alloy substrate is selected;

[0021] Step 102, pre-treating the surface of the substrate, and the aluminum alloy substrate is degreased, ultrasonically cleaned, and dried, and is ready for use;

[0022] Step 103, micro-arc oxidation treatment, the cleaned aluminum alloy substrate is put into 4-6 g / L KOH electrolyte, the metal substrate is the anode, and the stainless steel is the cathode, and the micro-arc oxidation treatment is performed. By controlling the process parameters such as voltage and time, a ceramic layer with a thicknes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com