Multi-stag ion fluidizing device and method

A jet device and multi-stage technology, which is applied in the field of multi-stage ion jet devices, can solve the problem of not being able to provide a propeller that meets the requirements, and achieve the effects of increasing the amplitude, increasing the efficiency and increasing the power.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A kind of ion jet method, concrete steps are:

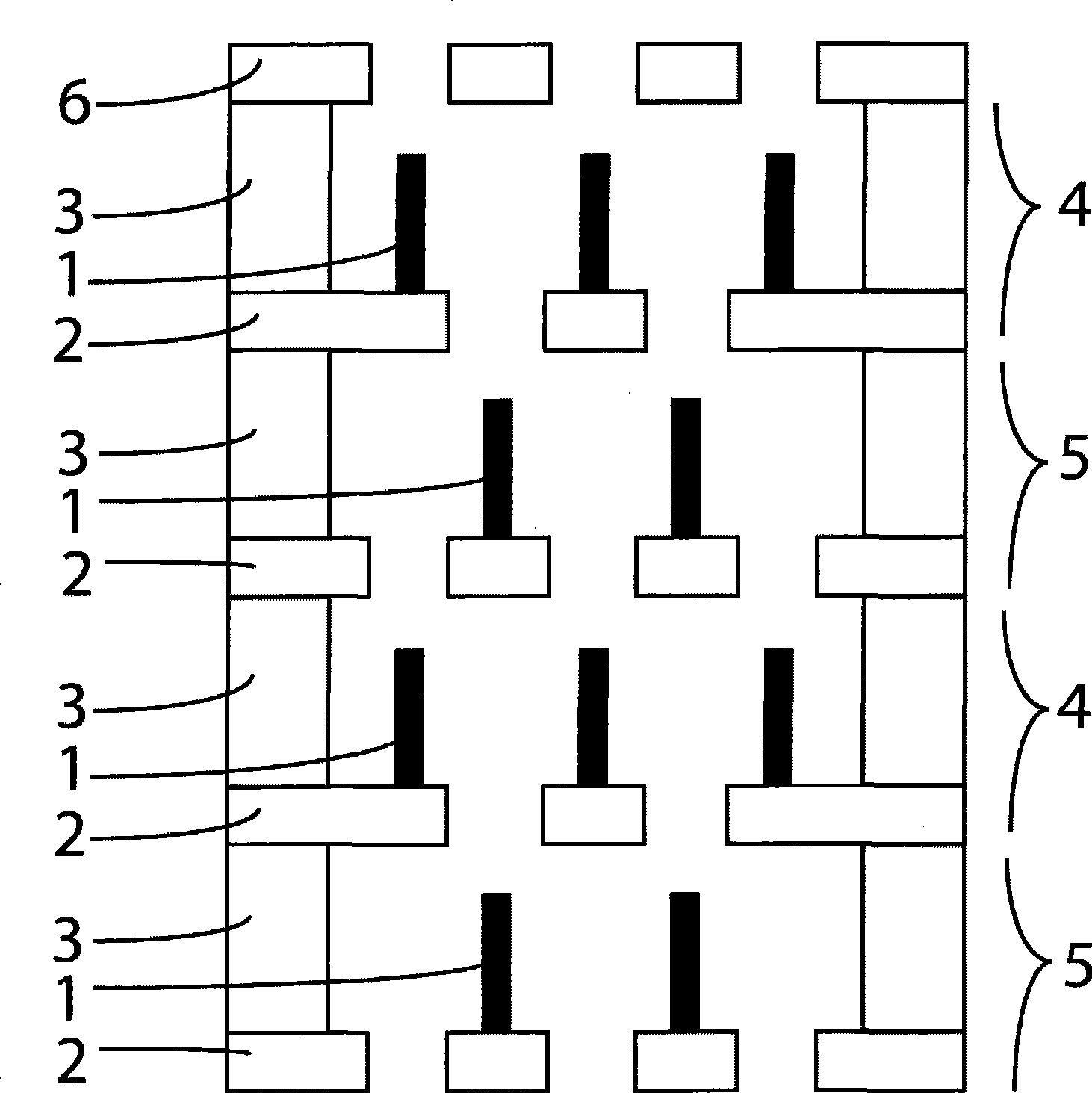

[0036] first step, such as figure 1 As shown, a multi-stage ion jet structure is formed, the number of stages is four, each accelerating electrode constitutes one stage, and each accelerating electrode is composed of a silicon wafer, and multiple first accelerating electrodes and second accelerating electrodes are arranged alternately, The final structure is formed by "silicon oxide-silicon oxide" bonding. The structure of the multi-stage ion jet device involved in this embodiment is as follows:

[0037] Including the first accelerating electrode 4, the second accelerating electrode 5 and the end hollow electrode 6, the first accelerating electrode 4 and the second accelerating electrode 5 are alternately arranged to form a multi-level electrode structure, every two adjacent first accelerating electrodes 4 and Between the second accelerating electrodes 5, an insulating layer is arranged so that the two are insulated from ...

Embodiment 2

[0046] A kind of ion jet method, concrete steps are:

[0047] first step, such as figure 1 As shown, the structure of the multi-stage ion jet device is as in Example 1.

[0048] In the second step, the loading voltages on the accelerating electrodes at each level are 100V, 75V, 50V, and 25V respectively, and the hollow electrodes at the end are grounded. The test is carried out in a vacuum chamber, the gas in the vacuum chamber is normal pressure air, which is pumped to 10 -4 The air pressure of Pa, through the air inlet of the vacuum chamber, a flexible gas supply channel is set to connect with the entrance of the ion jet device, and the gas sent in is N 2 Gas, the flow velocity is 5.1m / s, the flow velocity of the outflow gas is 12.4m / s, the mass flow velocity is 0.031g / s, after measurement, the thrust is about 230 micronewtons.

[0049] Examples 1 and 2 illustrate that the technical solution provided by the present invention can output a thrust of tens of micronewtons und...

Embodiment 3

[0051] A kind of ion jet flow method to generate air flow under normal pressure, its specific steps are:

[0052] first step, such as figure 1 As shown, the structure of the multi-stage ion jet device is as in Example 1.

[0053] In the second step, the loading voltages on the accelerating electrodes at each level are 200V, 150V, 100V, and 50V respectively, and the hollow electrodes at the ends are grounded. The test is carried out in air at normal pressure. During the test, the device is installed on the slide rail and moves at a speed of 0.001m / s in a direction parallel to the test platform. The flow velocity is 9.3m / s, and the mass flow velocity is 0.079g / s.

[0054] Compared with a conventional ion wind generating device, this device is composed of a needle-shaped electrode corona discharge structure with a gap of 350 microns and a needle tip with a minimum diameter of 20 microns. Its relatively stable operating voltage is between 4200-4900V. The velocity of the ion win...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com