Construction of surface conductive field emission electronic source conductive film

A technology of conductive film and electron source, applied in the direction of cathode ray tube/electron beam tube, discharge tube/lamp components, circuits, etc., can solve the problems of low emission current density, low electron emission rate, and low brightness of SED, and achieve The effect of increasing emission current density and electron emission rate, high carrier mobility, and low threshold voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

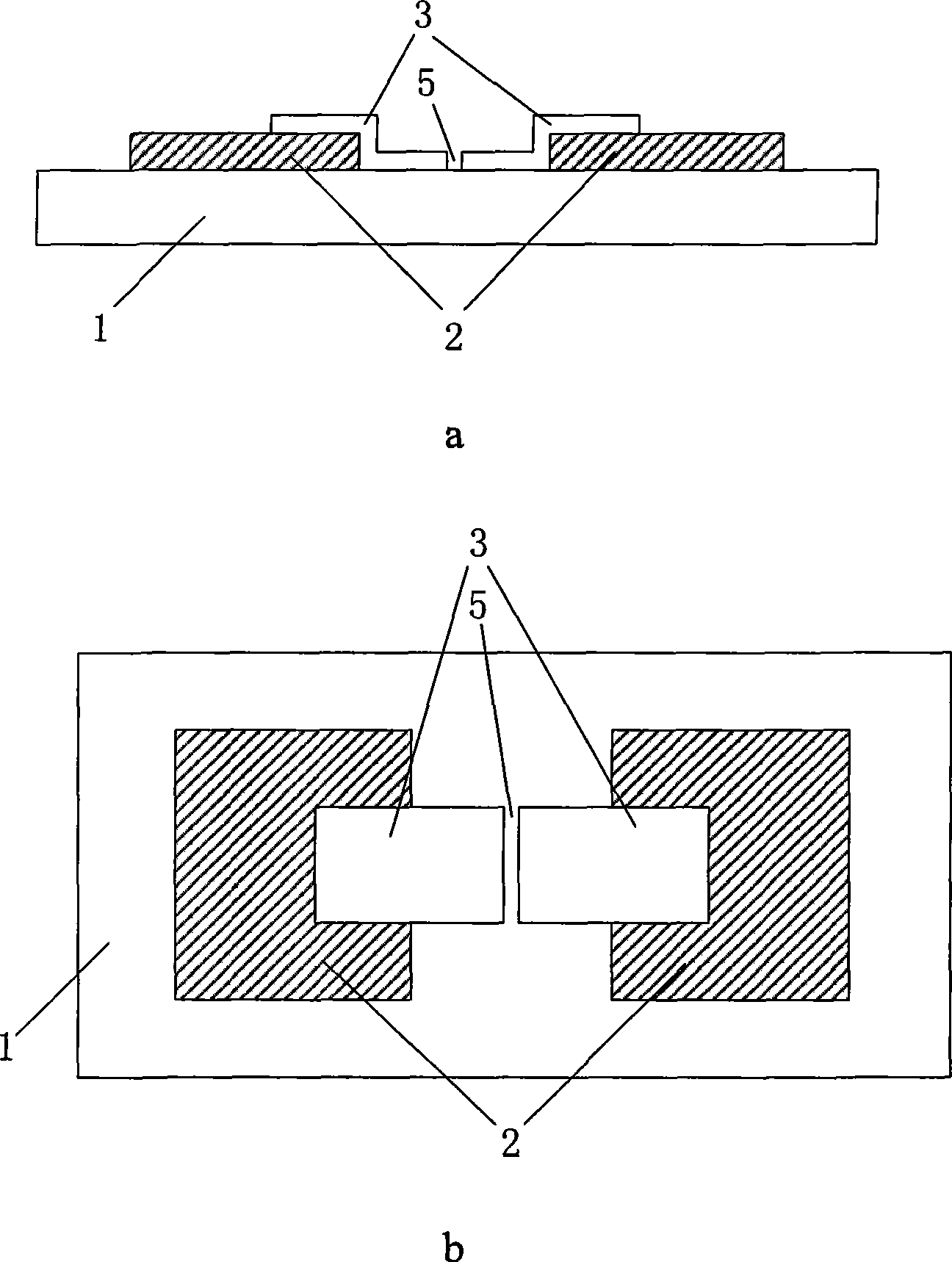

[0029] refer to figure 1 As shown, the manufacturing process of the conductive film is to make the PdO film 3 on the glass substrate 1 with the device electrode 2 and other components, so the conductive film is a single-layer material film, and then the film is "formed with power" process to obtain the gap 5.

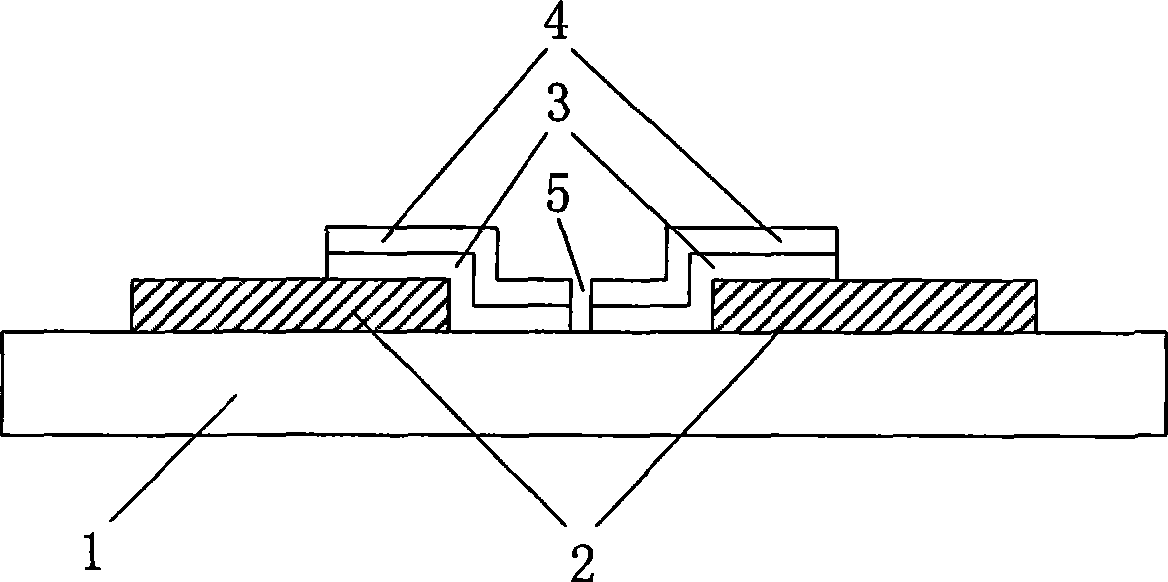

[0030] refer to figure 2 As shown, the manufacturing process of the conductive film is to first make a palladium oxide PdO film 3 on a glass substrate 1 with components such as device electrodes 2, and then make an amorphous carbon film 4 on it, thereby forming two layers of PdO-amorphous carbon structure conductive film, and finally perform the process of “power-on formation” on the film to obtain the gap 5 .

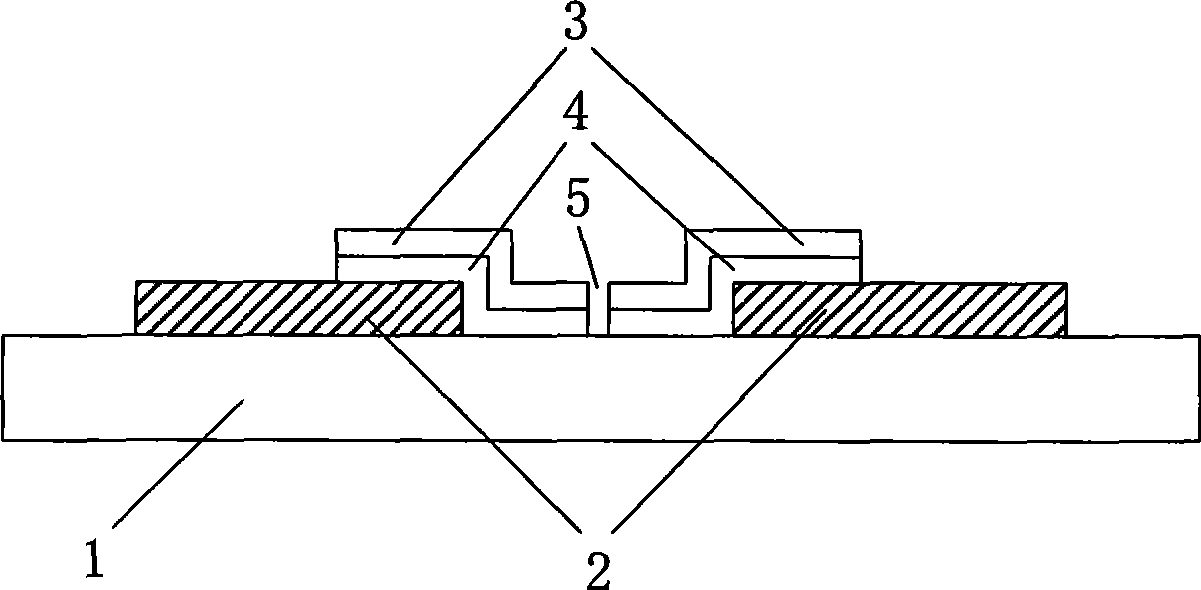

[0031] refer to image 3 As shown, the manufacturing process of the conductive film is to first make an amorphous carbon film 4 on a glass substrate 1 with components such as device electrodes 2, and then make a palladium oxide PdO film 3 on it, thereby form...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com