Preparation method of cuprum cerium composite oxides catalyst

A technology of composite oxides and catalysts, applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problem of low reaction activity, long time-consuming, cumbersome catalyst process and other problems to achieve the effect of overcoming the cumbersome process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

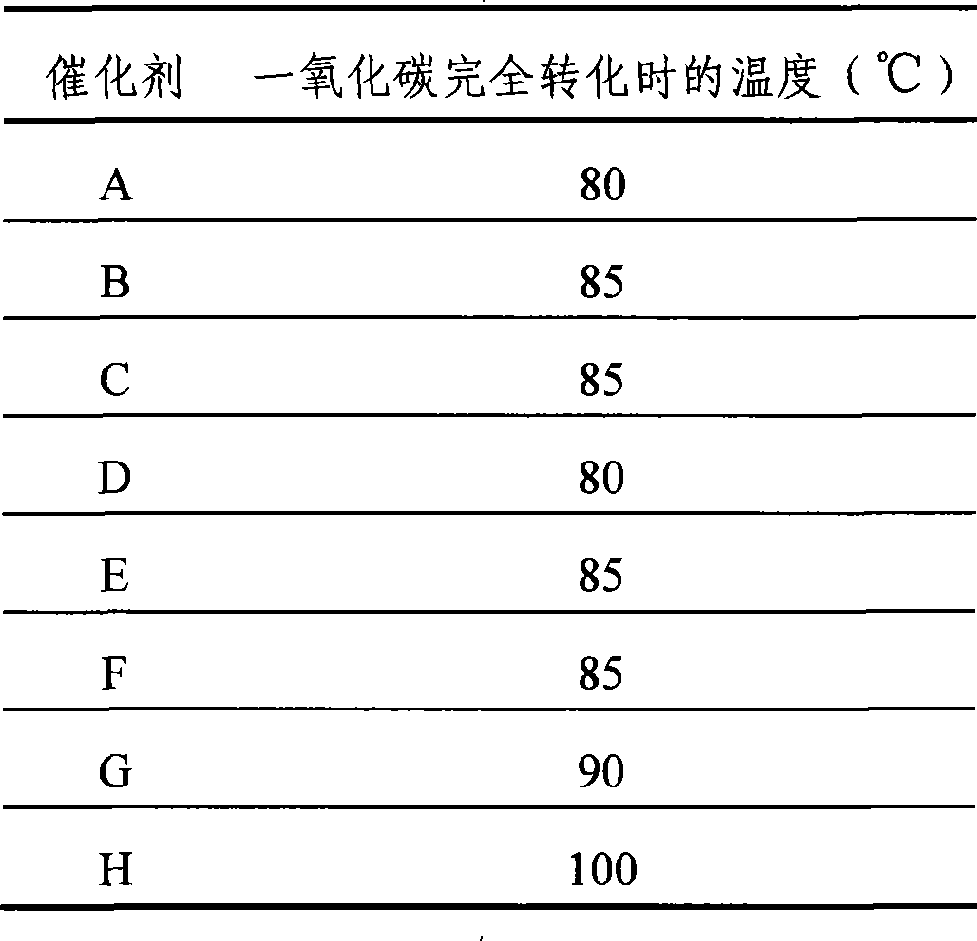

Embodiment 1

[0023] 2.42 grams of copper nitrate and 39.1 grams of cerium nitrate were dissolved in 100 milliliters of ethanol, then 2.3 grams of citric acid were added and stirred to completely dissolve. Heating in a water bath at 80°C and stirring continuously until a sol is produced, and quickly transferring it to a large container previously heated at 120°C, the sol foams rapidly to form a fluffy and porous gel precursor. After drying for 2 h, calcining at 650 °C for 4 h in a muffle furnace to obtain CuO / CeO 2 Catalyst A.

Embodiment 2

[0025] Prepare CuO / CeO with embodiment 1 2 Catalysts B and C just replace ethanol with propanol and butanol, respectively.

Embodiment 3

[0027] Prepare CuO / CeO with embodiment 1 2 Catalysts D and E, but the addition of citric acid is respectively 1.54 grams and 3.46 grams.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com