Method for treating waste water after workpiece tinplating

A wastewater treatment and workpiece technology, which is applied in metallurgical wastewater treatment, water/sewage treatment, water/sewage multi-stage treatment, etc., can solve problems such as failure to meet discharge standards, complex engineering devices, waste of water resources, etc., and achieve infrastructure investment and The effect of reducing construction time, convenient operation and management, and saving processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

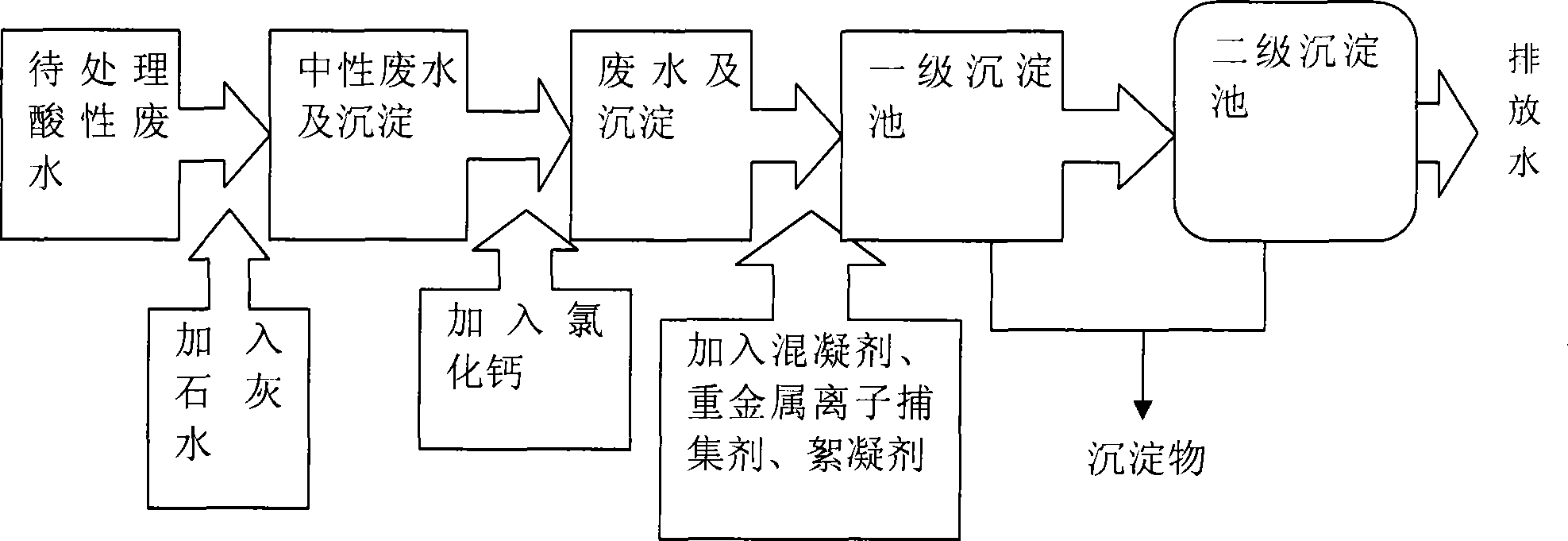

[0012] Refer to figure 1 , The method for treating wastewater after tin-plating a workpiece of the present invention adds lime water (Ca(OH)) to the acidic wastewater to be treated 2 ), through the combination of hydroxide ions in lime water with copper ions and tin ions to form copper hydroxide precipitation and tin hydroxide precipitation, and through the combination of calcium ions contained in lime water and sulfate ions to form slightly soluble calcium sulfate precipitation, reverse The formula is as follows:

[0013] H + +OH - →H 2 O; Cu 2+ +2OH - →Cu(OH) 2 ↓; Ca 2+ +SO 4 2- →CaSO 4 ↓

[0014] Sn 2+ Sn is obtained after oxidation 4+ , Sn 4+ Sn(OH) is obtained by hydrolysis 4 ↓;

[0015] Through the above treatment, the acid wastewater can be adjusted to neutral wastewater, and the pH of the neutral wastewater is 6-8. Add soluble calcium chloride (CaCl 2 ), the residual sulfate ions combine with calcium ions to form a slightly soluble calcium sulfate precipitate (CaSO 4 ). T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com