Ultralong Fabry-Parot interferent gas sensor and gas tester based on the sensor

A technology of gas sensor and gas tester, which is applied in the field of gas tester, can solve the problems of easy pollution, light source fluctuation, long gas chamber volume, etc., and achieve the effect of easy networking, good stability and simple system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

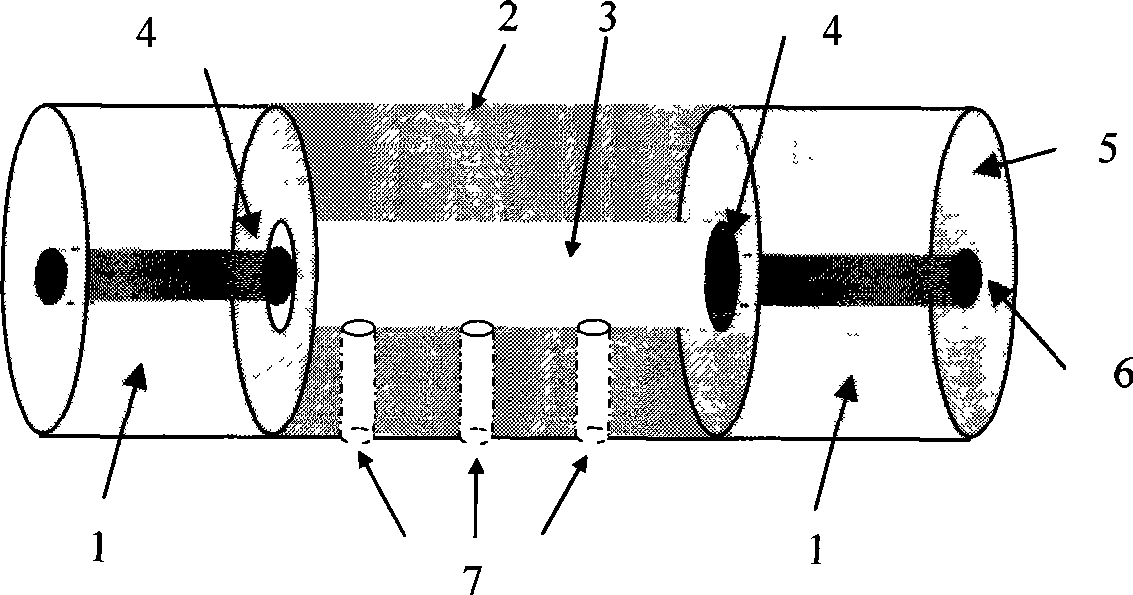

[0021] Embodiment 1: In the case of processing air-permeable microholes 7 on the hollow-core photonic crystal fiber 2, the air-permeable microholes 7 that are distributed in an array can be directly processed radially on the hollow-core photonic crystal fiber 2, such as figure 1 shown.

Embodiment 2

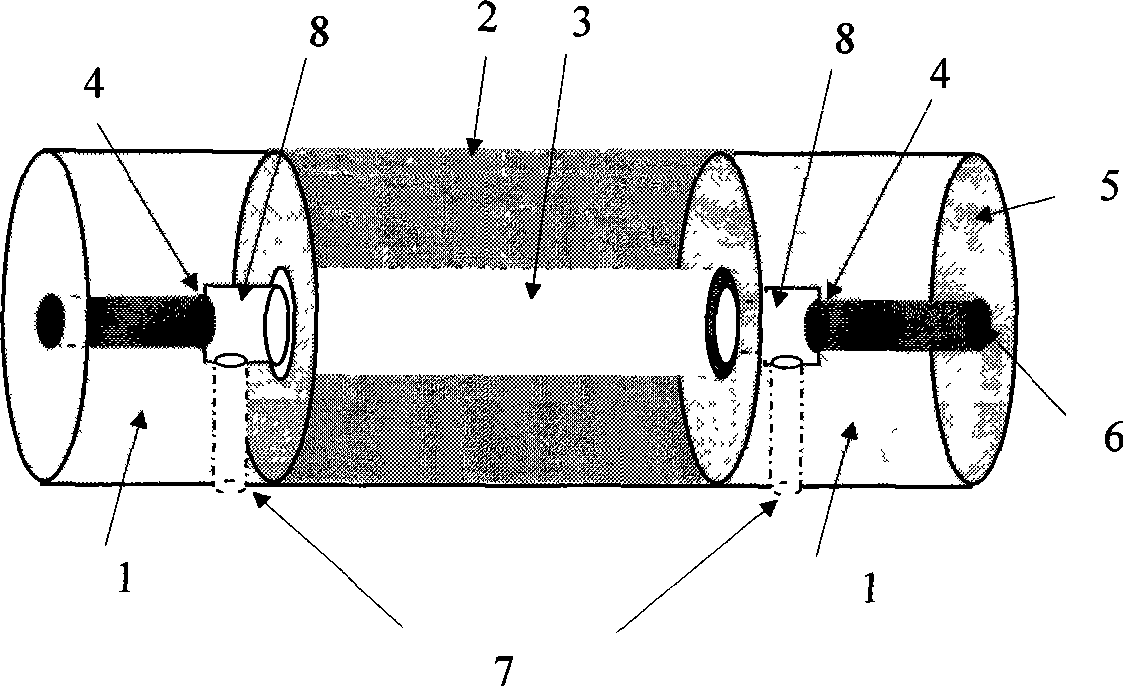

[0022] Embodiment 2: In the case of processing the air-permeable microhole 7 on the single-mode optical fiber 1, in this embodiment, it is also necessary to process the microhole 8 at the end of the single-mode optical fiber 1 and the hollow-core photonic crystal fiber 2 fusion, and the microhole 8 The end face of the single-mode optical fiber 1 is coated with a reflective film; the air-permeable microholes 7 distributed in an array are radially processed on the cladding of the single-mode optical fiber 1, and the core of the hollow-core photonic crystal fiber 2 communicates with the outside world through the microholes 8 and the air-permeable microholes 7 ,like figure 2 shown.

[0023] Because the laser has good focusing performance, it can make the light spot converge to the wavelength level, concentrate high energy in a small area, and the heat-affected area is small, so as to realize "cold processing" in a relative sense. Therefore, an array of gas inlet and outlet micro...

Embodiment 3

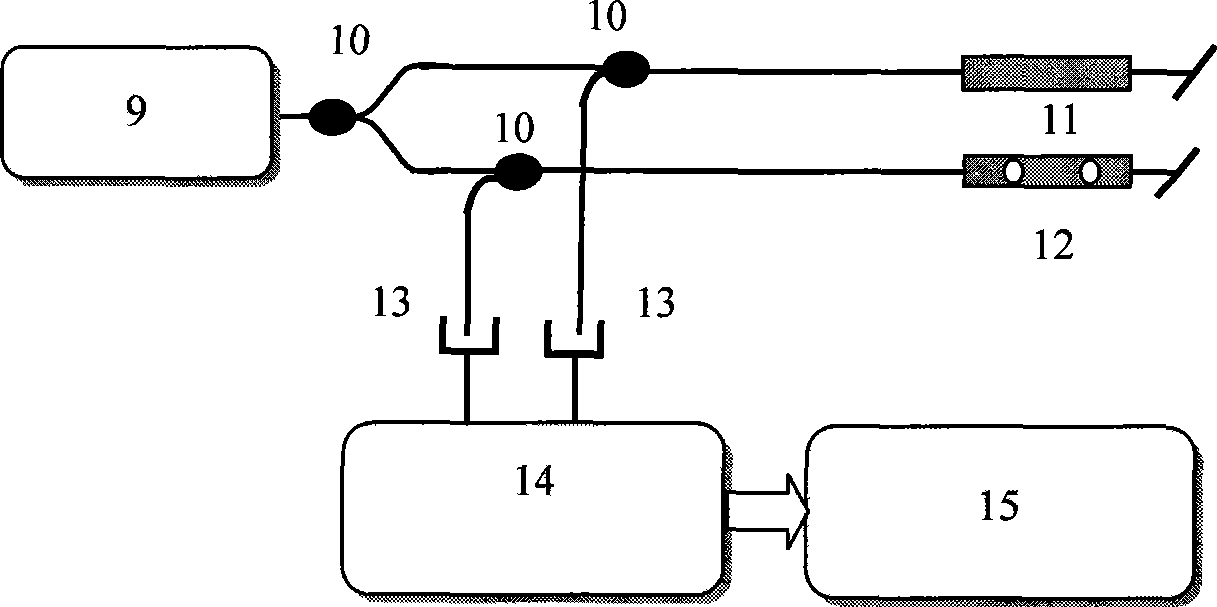

[0027] attached image 3 It is a structural schematic diagram of an embodiment of a gas tester based on an ultra-long FA-P interferometric gas sensor in the present invention. The gas tester includes a frequency-sweeping laser 9, an optical coupler 10, a sensing interference cavity 11 and a reference interference cavity 12 using an ultra-long FA-P interferometric gas sensor, a photodetector 13, a data receiving and signal processing circuit 14 and Monitoring computer 15.

[0028] It can be seen from the figure that the frequency-sweeping laser 9 is used as an optical signal source, and its input wavelength range can be selected according to the short section near the strongest absorption peak of the gas to be measured. Its wavelength bandwidth is very narrow, and can almost be treated as a single wavelength. After the light emitted by the frequency-sweeping laser 9 passes through the ordinary optical fiber, the light is divided into two beams by the optical coupler 10. One be...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com