Catalyst multistage regeneration method and device

A catalyst and two-stage regeneration technology, which is applied in the direction of catalyst regeneration/reactivation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of low initial reaction temperature of the spent agent and difficulty in meeting the requirements, and achieve reduction Residence time, height reduction, and activity-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

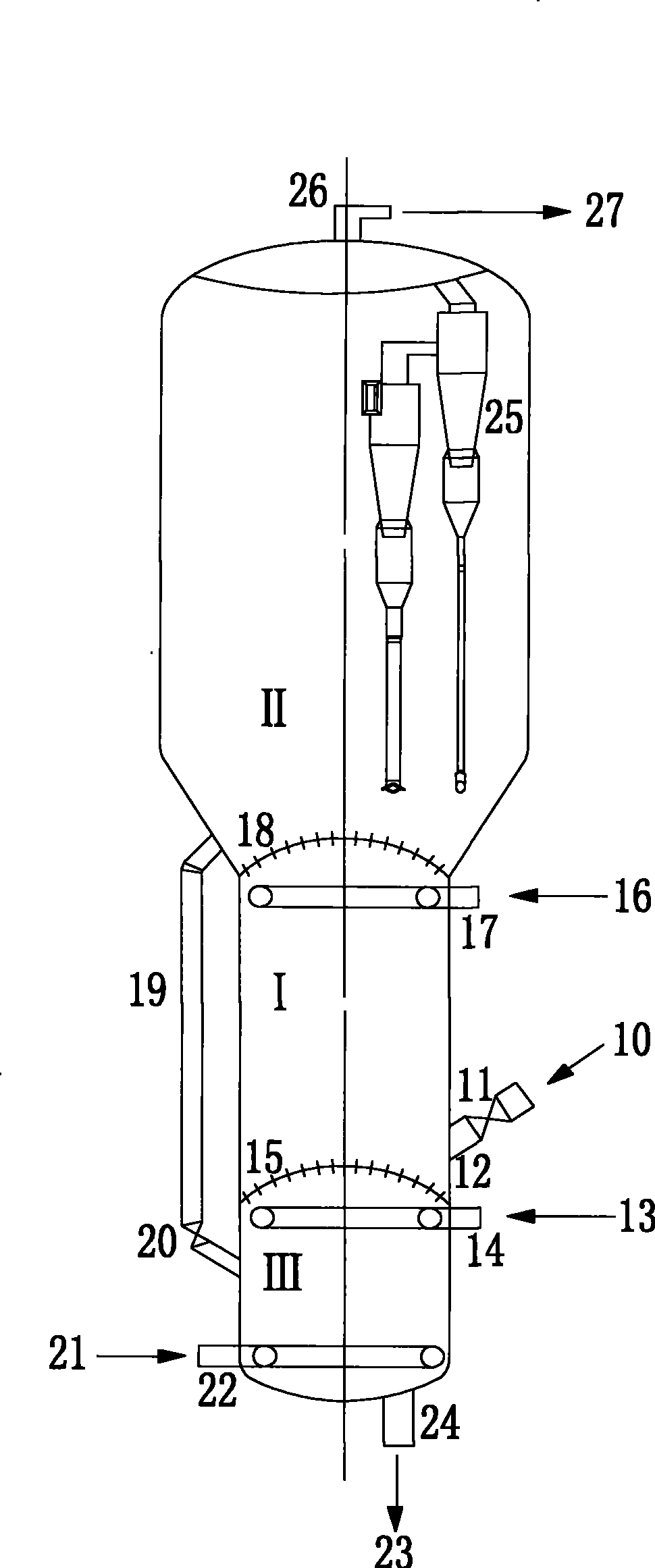

Embodiment 1

[0040] Example 1: A certain 100×10 4 The t / a catalytic cracking unit is regenerated with compressed air at 200°C. Such as Figure 4 and figure 1 As shown, the carbon content of the regenerated agent 10 is 1.3%, the temperature is 490° C., the carbon content of the outgoing regenerated agent 23 is 0.05%, and the oxygen content in the flue gas 27 at the outlet of the regenerator is about 1%. The distribution plate 15, 18 through-hole flow velocity is 15-20m / s, and the amount of catalyst returned through the return pipe 19 is 2.5 times of the circulation volume of the spent agent, 1.5 times of which enters the first-stage regenerator from the distribution plate 15, and increases the first-stage regeneration temperature. The catalyst in the second stage regenerator enters the third stage after being cooled by the external heat collector 50, and 51 is a slide valve.

[0041] The regeneration temperature, air intake volume, superficial gas flow velocity, char ratio and device hei...

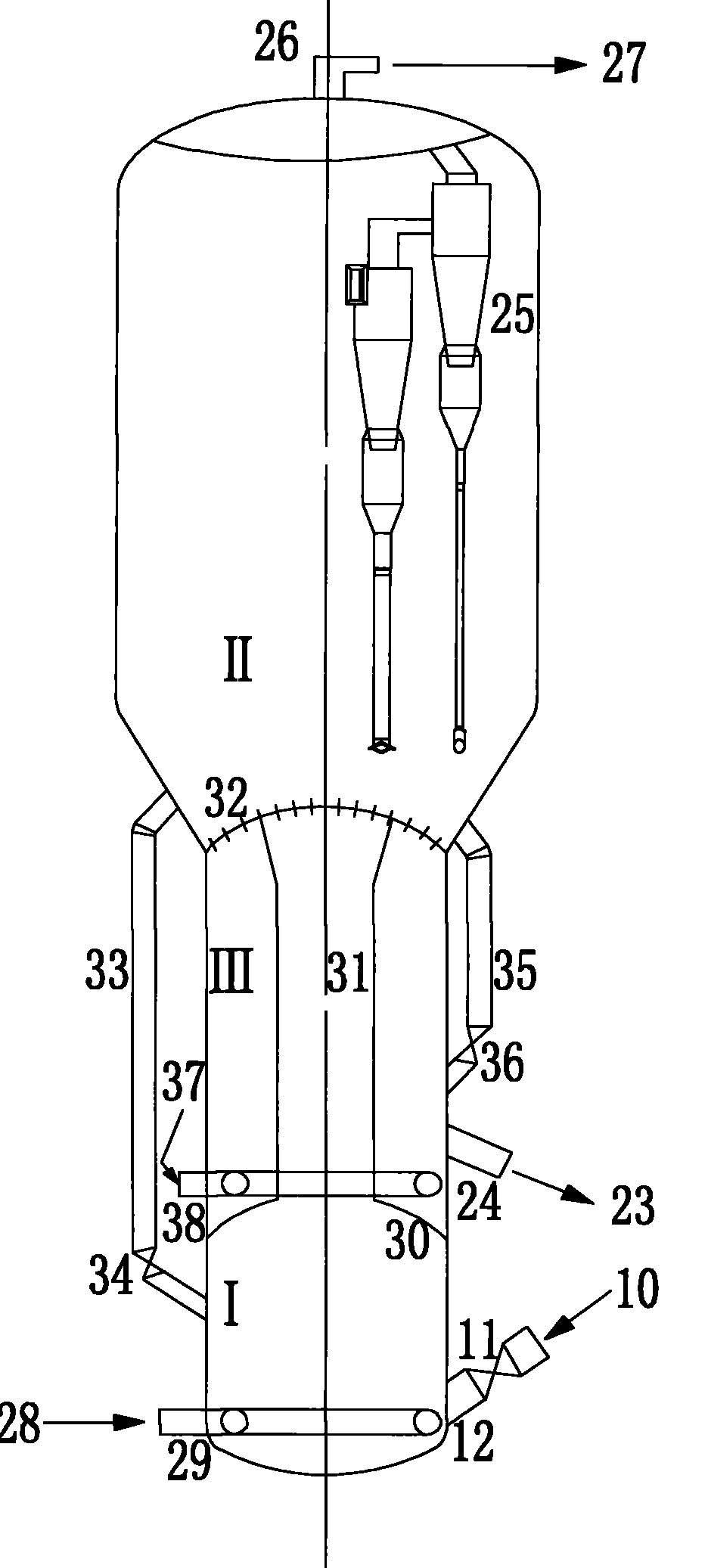

Embodiment 2

[0048] Embodiment 2: device structure such as figure 2 As shown, the gas superficial flow velocity of each section is 1.2m / s for the first section, 0.8m / s for the second section, and 0.8m / s for the third section; 8m high. The amount of catalyst returned through the return pipe 33 is 1.2 times of the amount to be generated, and the amount of catalyst returned through the catalyst return pipe 35 is 1.5 times of the amount to be generated. Other processing parameters are as embodiment 1.

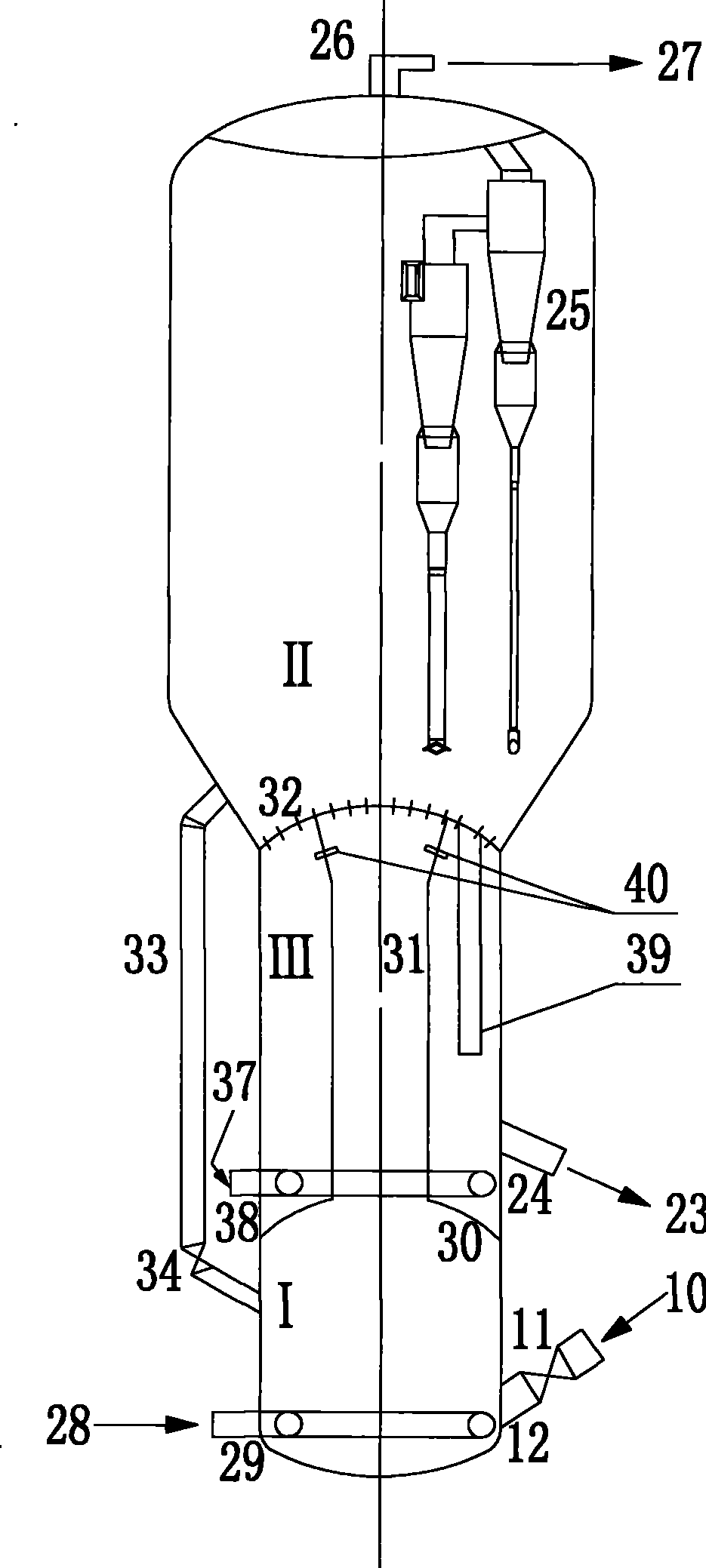

Embodiment 3

[0049] Embodiment 3: device structure such as image 3 As shown, the catalyst entering the third section through the catalyst return pipe 39 is 1.0-2.0 times of the amount to be produced. Others are the same as embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com