Full-automatic gypsum block extrusion molding production chain

A kind of extrusion molding, gypsum block technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

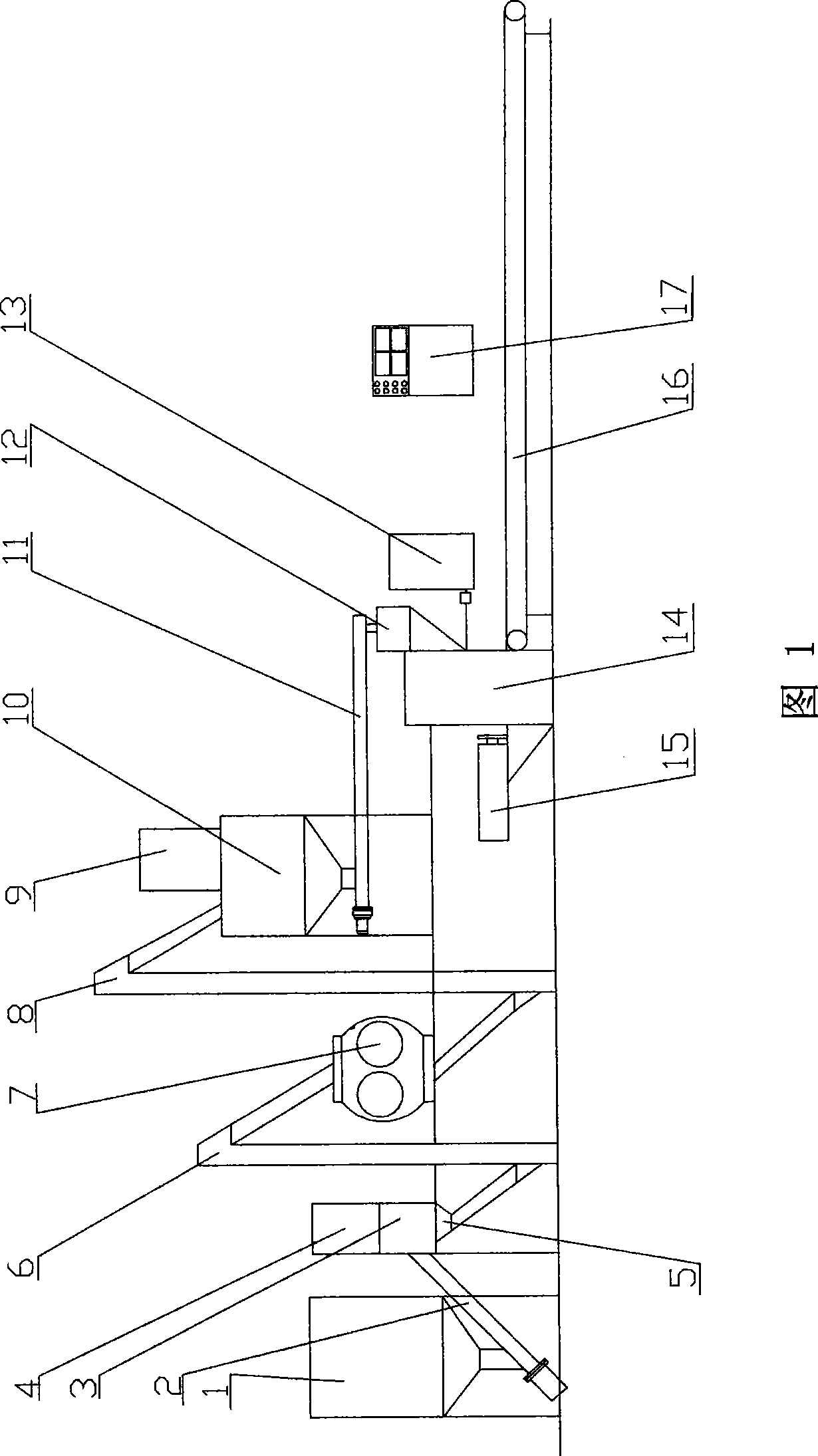

[0009] Referring to Fig. 1, the full-automatic gypsum extrusion molding production line of this embodiment of the present invention, wherein 2 sets of metering screw conveyors are selected from the commercially available SSJ-I type, and 2 sets of dust collectors are selected from the commercially available DMC type pulse-jet bag dust collector. Two sets of elevators are selected from the commercially available GYTS-1 bucket elevator, and the rest are selected from the supporting equipment produced by Hunan Yabang Building Materials Technology Development Co., Ltd.

[0010] The above-mentioned components are implemented according to the above-mentioned technical scheme of the present invention with reference to the layout shown in Fig. 1, that is, the fully automatic gypsum block extrusion molding production line of this embodiment of the present invention, the bottom feeding ports of the 2 raw material bins 1 are connected with the 2 metering augers respectively. Conveyors 2 fe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com