Inorganic composite conditioner and sludge dewatering method thereof

An inorganic composite and conditioning agent technology, applied in the direction of dehydration/drying/thickened sludge treatment, etc., can solve the problems of complex preparation process and achieve the effect of improving dehydration performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

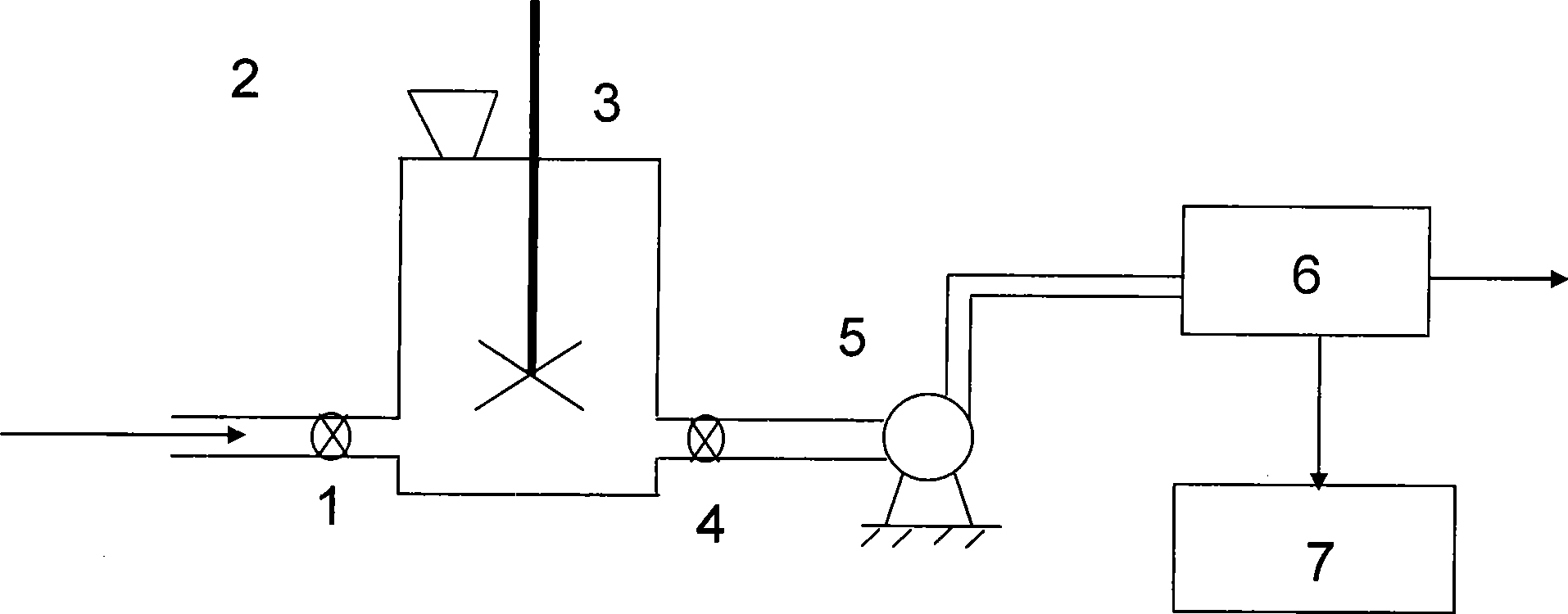

Image

Examples

Embodiment 1

[0025] The raw material components and percentage weight ratio of the inorganic composite conditioner are: 17% of fly ash and 83% of quicklime.

[0026] The dehydration method is as follows: add 6% inorganic composite conditioner to the remaining sludge in the secondary settling tank and stir to make the conditioner and sludge evenly mixed, then enter the plate and frame filter press through the sludge pump for dehydration, and obtain a sludge with a moisture content of 57.6%. Mud cake. The adjusted sludge specific resistance is 1.33×10 7 S 2 / g.

Embodiment 2

[0028] The raw material components and percentage weight ratio of the inorganic composite conditioner are: 37.5% of fly ash and 62.5% of quicklime.

[0029] The dehydration method is

[0030] Add 8% inorganic composite conditioner to the remaining sludge in the secondary settling tank and stir to make the conditioner and sludge evenly mixed, then enter the sludge dehydrator through the sludge pump for dehydration, and obtain a mud cake with a moisture content of 52.4%. The adjusted sludge specific resistance is 1.3×10 7 S 2 / g.

Embodiment 3

[0032] The raw material components and percentage weight ratio of the inorganic composite conditioner are: 50% of fly ash and 50% of quicklime.

[0033] The dehydration method is:

[0034] Add 10% inorganic composite conditioner to the residual sludge in the secondary settling tank and stir to make the conditioner and sludge evenly mixed, then enter the plate and frame filter press for dehydration through the sludge pump, and obtain a mud cake with a moisture content of 49.25%. The adjusted sludge specific resistance is 5.7×10 6 S 2 / g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com