Reactor for synthesizing dimethyl ether by biomass synthesis gas through one-step method and temperature control system

A technology of temperature control system and reactor, which is applied in the field of reactor system, can solve problems such as difficult to scale up and large latent heat, and achieve the effects of low system maintenance cost, high conversion efficiency and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

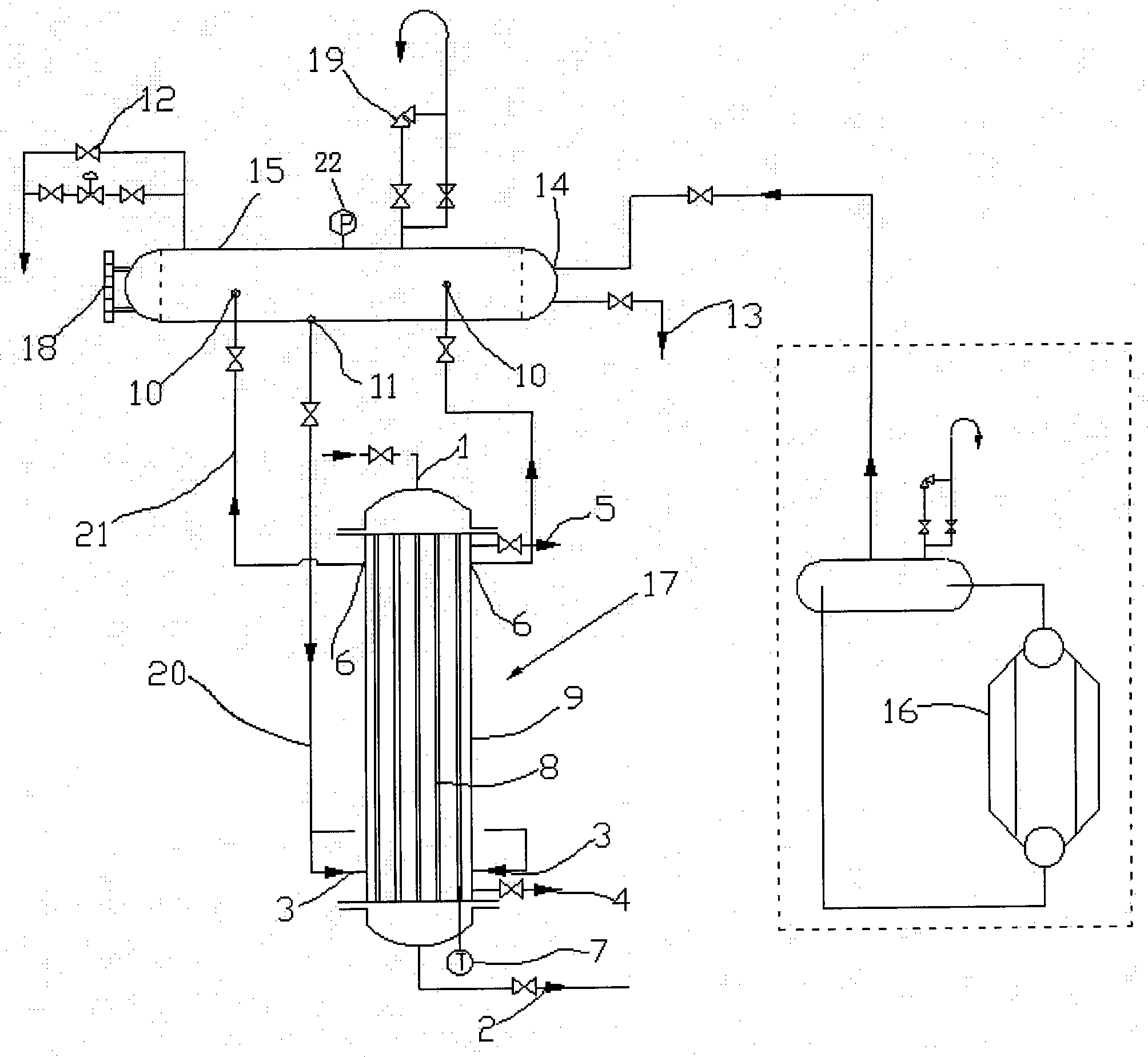

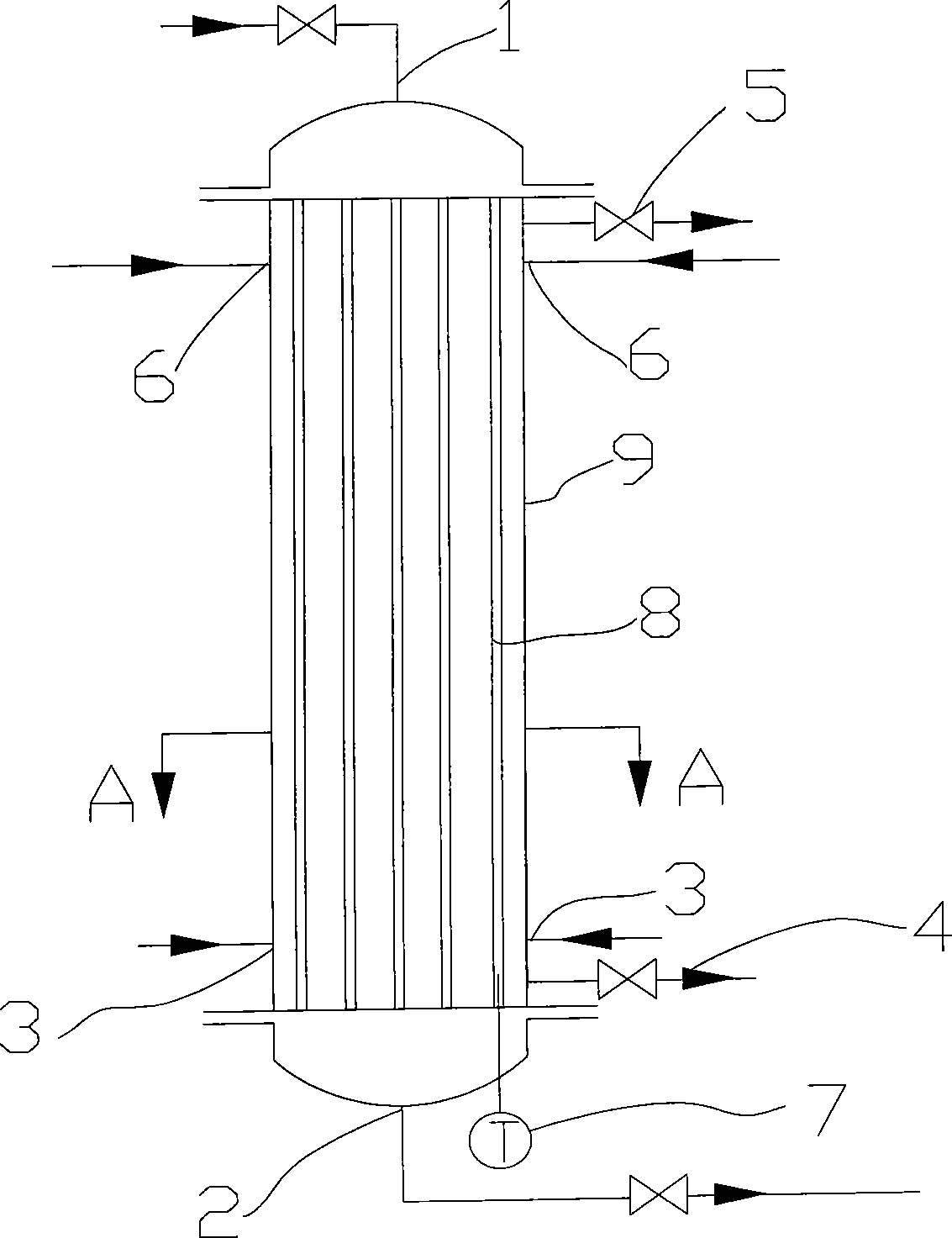

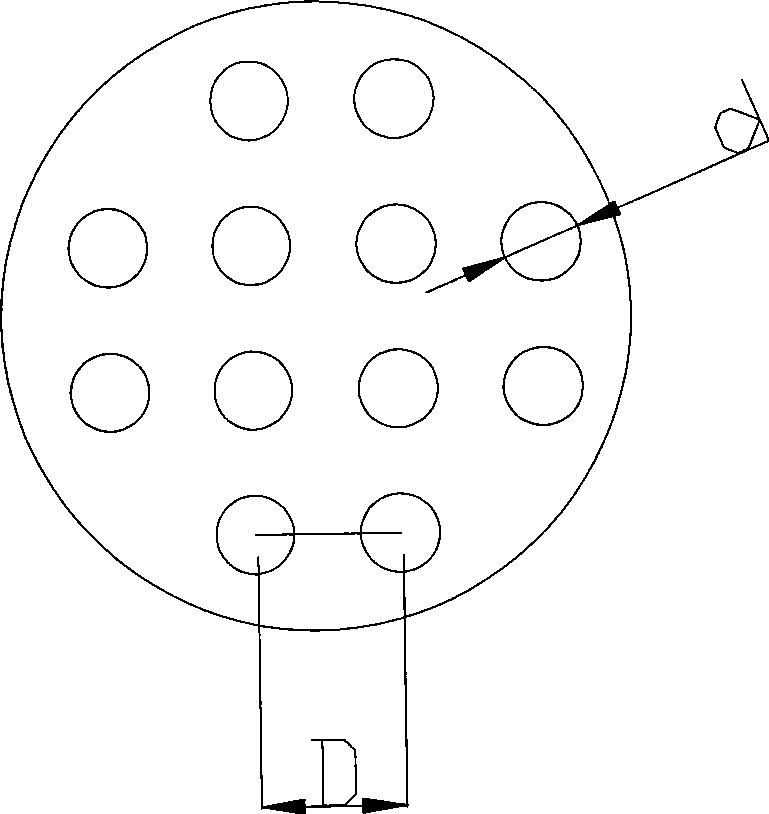

[0027] Such as Figure 1 to Figure 3 As shown, the reactor and temperature control system for one-step synthesis of dimethyl ether from biomass synthesis gas in this embodiment are mainly composed of a steam drum 15 , a boiler 16 and a fixed-bed reactor 17 . Its fixed-bed reactor 17 is a tubular fixed-bed reactor. In the fixed-bed reactor 17, there are 36 reaction tubes 8 parallel to the longitudinal direction of the reactor 17. The diameter of the reaction tubes 8 is 40 mm, adjacent to each other. The distance D between the tube cores of the two reaction tubes 8 is 2.5 times of the diameter d of the reaction tubes 8, which is 100mm in this embodiment; a reaction gas inlet 1 is arranged on the top of the fixed bed reactor 17, and the reactor near the top The shell side 9 of 17 is provided with an exhaust port 5, and superheated water outlets 6 are arranged on both sides of the reactor 17 near the exhaust port 5; the bottom end of the fixed bed reactor 17 is provided with a rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com