Novel circulation-type packed bed reactor

A packed bed reactor, circulating technology, applied in bioreactor/fermenter combination, specific-purpose bioreactor/fermenter, biochemical instruments, etc., can solve the problem that cells cannot be reused, the fermentation effect is not ideal, and the reaction Slow speed and other problems, to achieve the effect of being conducive to growth and reproduction and biosynthesis of products, increasing cell density and tolerance to toxicity, and improving yield and content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to describe the technical content and structural features of the present invention in detail, the following will be further described in conjunction with the embodiments and accompanying drawings.

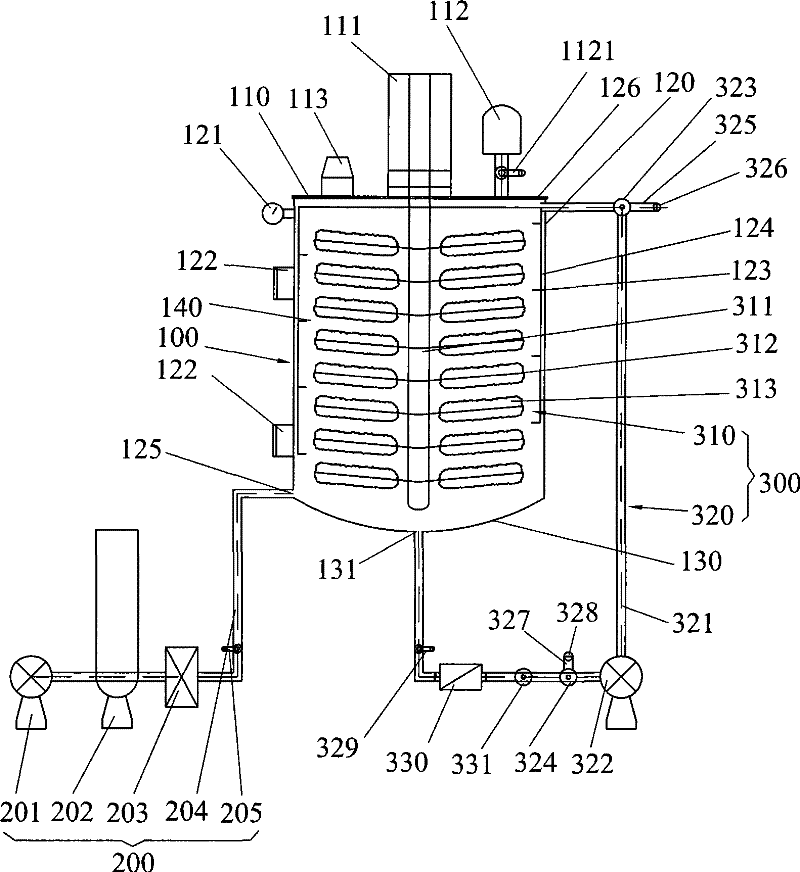

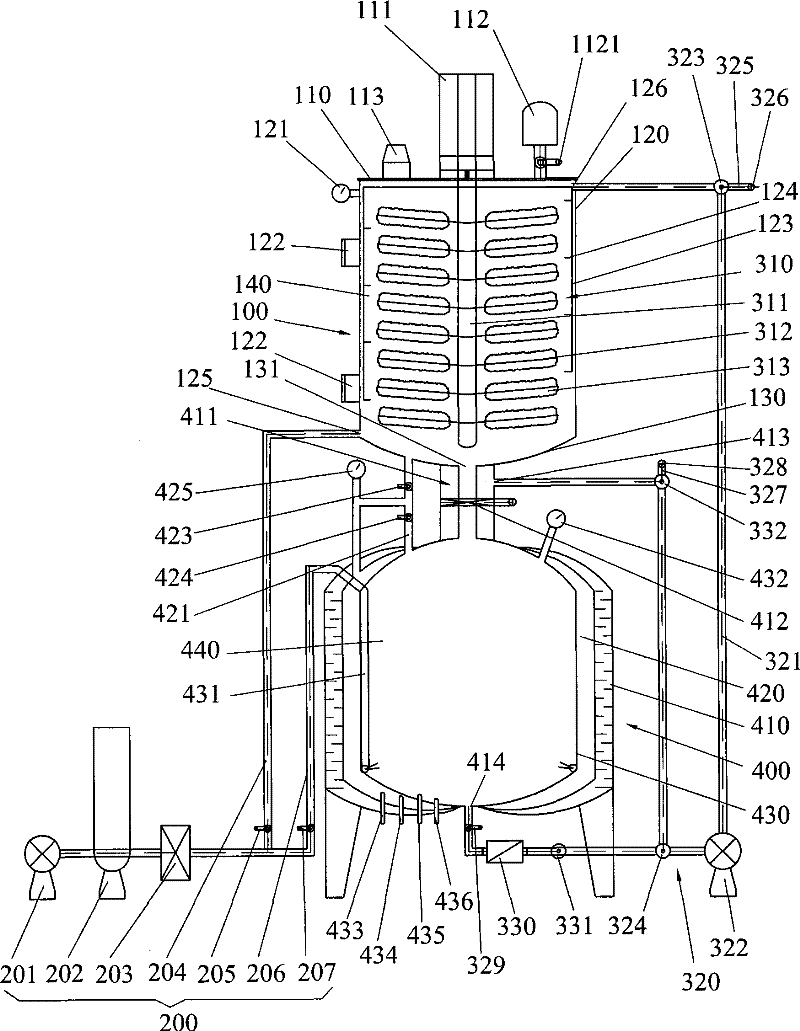

[0029] Such as figure 1 as shown, figure 1 A schematic composition diagram of the first embodiment of the circulating packed bed reactor of the present invention is shown, including a fermenter 100 , an aeration system 200 and a circulation system 300 .

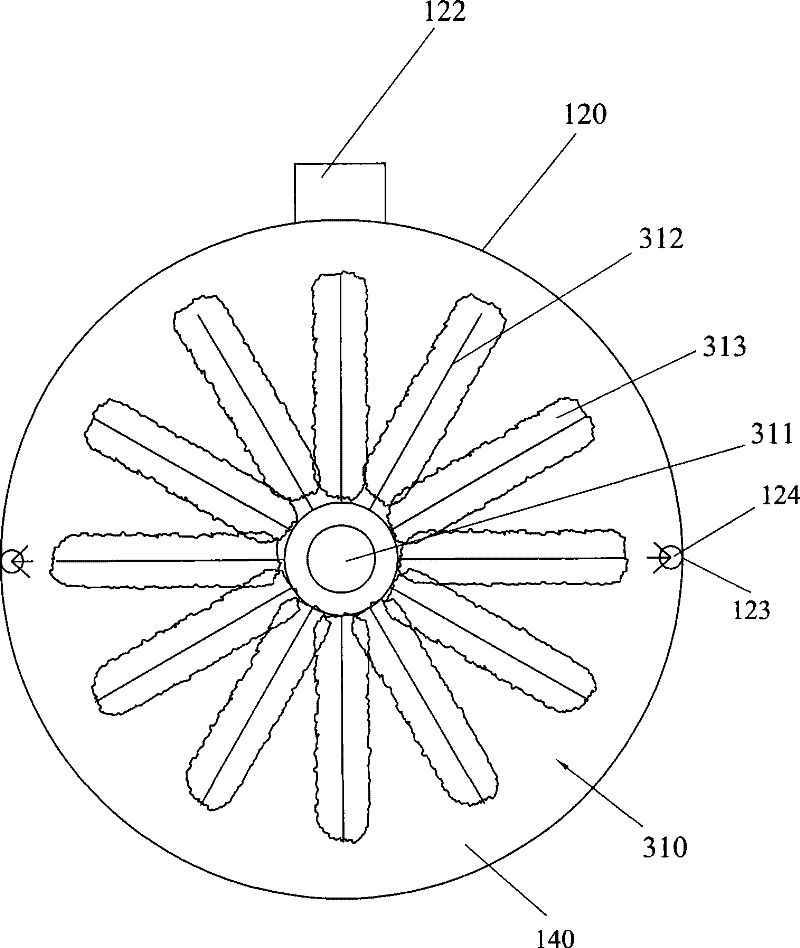

[0030] The fermenter 100 includes a fermenter top 110 , a side wall 120 , a bottom 130 and an inner cavity 140 . A speed-regulating motor 111 , a breathing valve 112 and a mirror lamp 113 are installed on the outer surface of the fermenter top cover 110 . A first valve 1121 is installed on the breathing valve 112 to control the switching of the breathing valve 112 . A pressure detection device 121 and two observation mirrors 122 are installed on the outside of the side wall 120 of the fermenter, and several flow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com