Fine iron pre-reduction technology suitable for wide grain size distribution and apparatus thereof

A fine iron ore, degree distribution technology, applied in chemical instruments and methods, chemical/physical processes, etc., can solve the problems of difficult design of conical fluidized bed height, difficult to meet high-quality fluidization requirements, etc., to achieve flexible design, Simple structure and the effect of preventing sticking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

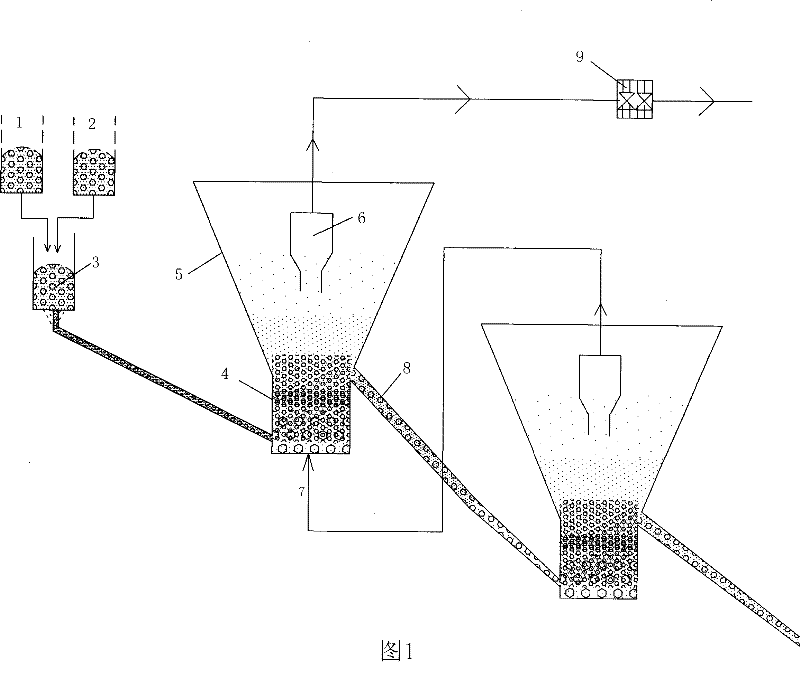

[0028] see figure 1 , powder iron ore 1 and flux 2 raw materials are mixed into the feed bin 3, raw materials (particle size2 %+CO% > 50%) is introduced from the bottom of the cylindrical fluidized bed 4, the gas velocity in the cylindrical fluidized bed 4 is 4m / s, and the large particle raw materials > 2mm maintain a turbulent state in the cylindrical fluidized bed 4 , the small particle size raw material is taken away from the cylindrical fluidized bed 4 step by step, and is stratified fluidized in the conical fluidized bed 5 (the taper is 20°). As the height rises, the cross-sectional area of the conical fluidized bed 5 increase, the gas flow rate also decreases correspondingly, the gas velocity at the upper end of the conical fluidized bed 5 is less than 0.5m / s, and a large amount of powdered ore raw materials are reversely mixed into the lower dense bed, and the particle size is less than 0.05mm and enters the hot cyclone separator 6. The separated fine powder raw mater...

Embodiment 2

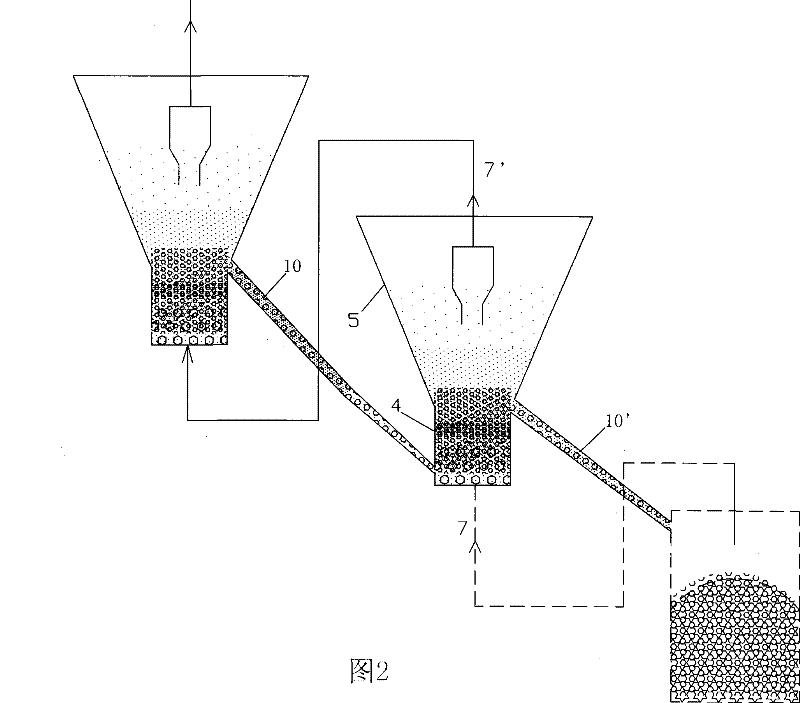

[0030] see figure 2 , the reactant raw material (particle size2 %+CO% > 60%) is introduced from the bottom of the cylindrical fluidized bed 4, the gas velocity in the cylindrical fluidized bed 4 is 24m / s, and the large particle raw materials > 2mm keep turbulent in the cylindrical fluidized bed 4 state, the small-grained raw materials are taken away from the cylindrical fluidized bed 4 step by step, and stratified fluidized in the conical fluidized bed 5 (the taper is 50°). As the area increases, the gas flow rate decreases accordingly. The gas velocity at the upper end of the conical fluidized bed 5 is less than 0.5m / s, and a large amount of powdered ore raw materials are reversely mixed into the lower dense bed, and the particle size is less than 0.05mm and enters the hot cyclone separator 6. , The separated fine powder raw materials are also mixed back into the lower dense bed. During the fluidization process, the pressure inside the fluidized bed is kept at 1.0MPa, and t...

Embodiment 3

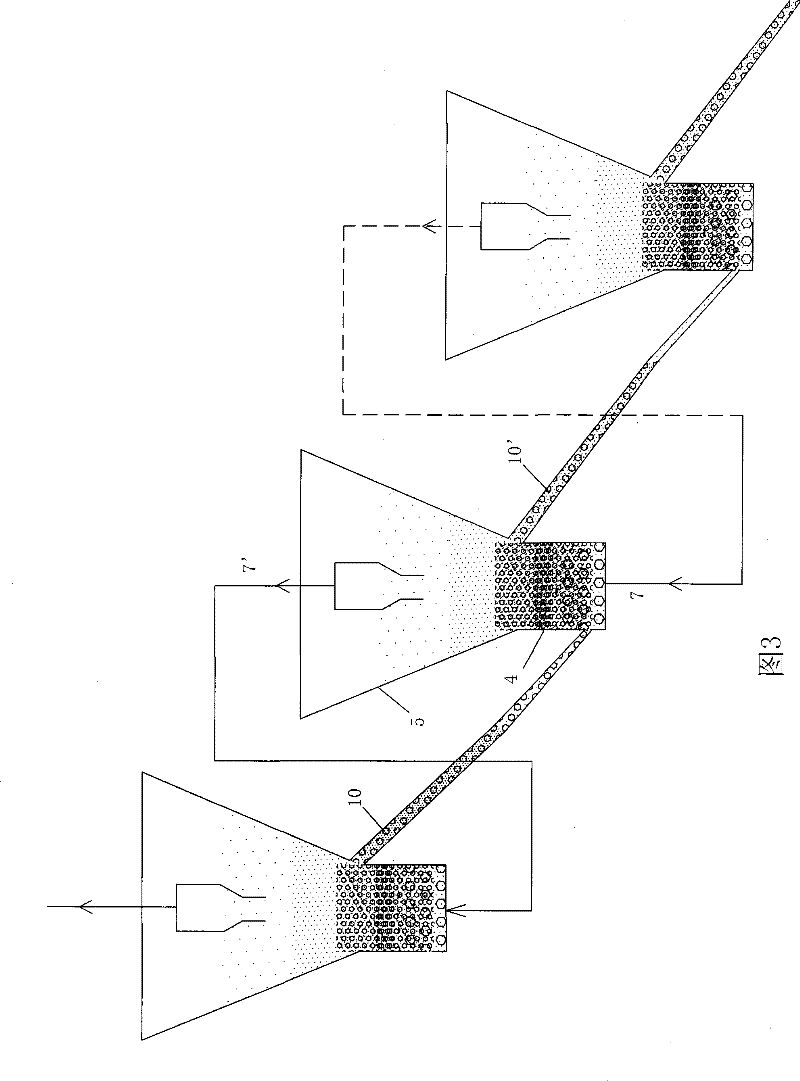

[0033] see image 3 , the reactant raw material (particle size2 %+CO% > 80%) is introduced from the bottom of the cylindrical fluidized bed 3, the gas velocity in the cylindrical fluidized bed 3 is 10m / s, and the large particle raw materials > 2mm keep turbulent in the cylindrical fluidized bed 3 state, the small-grained raw materials are taken away from the cylindrical fluidized bed 3 step by step, and are stratified fluidized in the conical fluidized bed 5 (the taper is 55°). As the area increases, the gas flow rate decreases accordingly. The gas velocity at the upper end of the conical fluidized bed 5 is less than 0.5m / s, and a large amount of powdered ore raw materials are reversely mixed into the lower dense bed, and the particle size is less than 0.05mm and enters the hot cyclone separator 6. , The separated fine powder raw materials are also mixed back into the lower dense bed. During the fluidization process, the pressure inside the fluidized bed is kept at 0.9MPa, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com