Energy recovery system of hybrid single-pump multi-execution component engineering machinery

A construction machinery and hybrid technology, applied in the field of energy recovery systems, can solve problems such as affecting energy recovery efficiency, complex energy flow, and bulky volume, so as to avoid oil throttling losses, improve recovery efficiency, and reduce installed space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

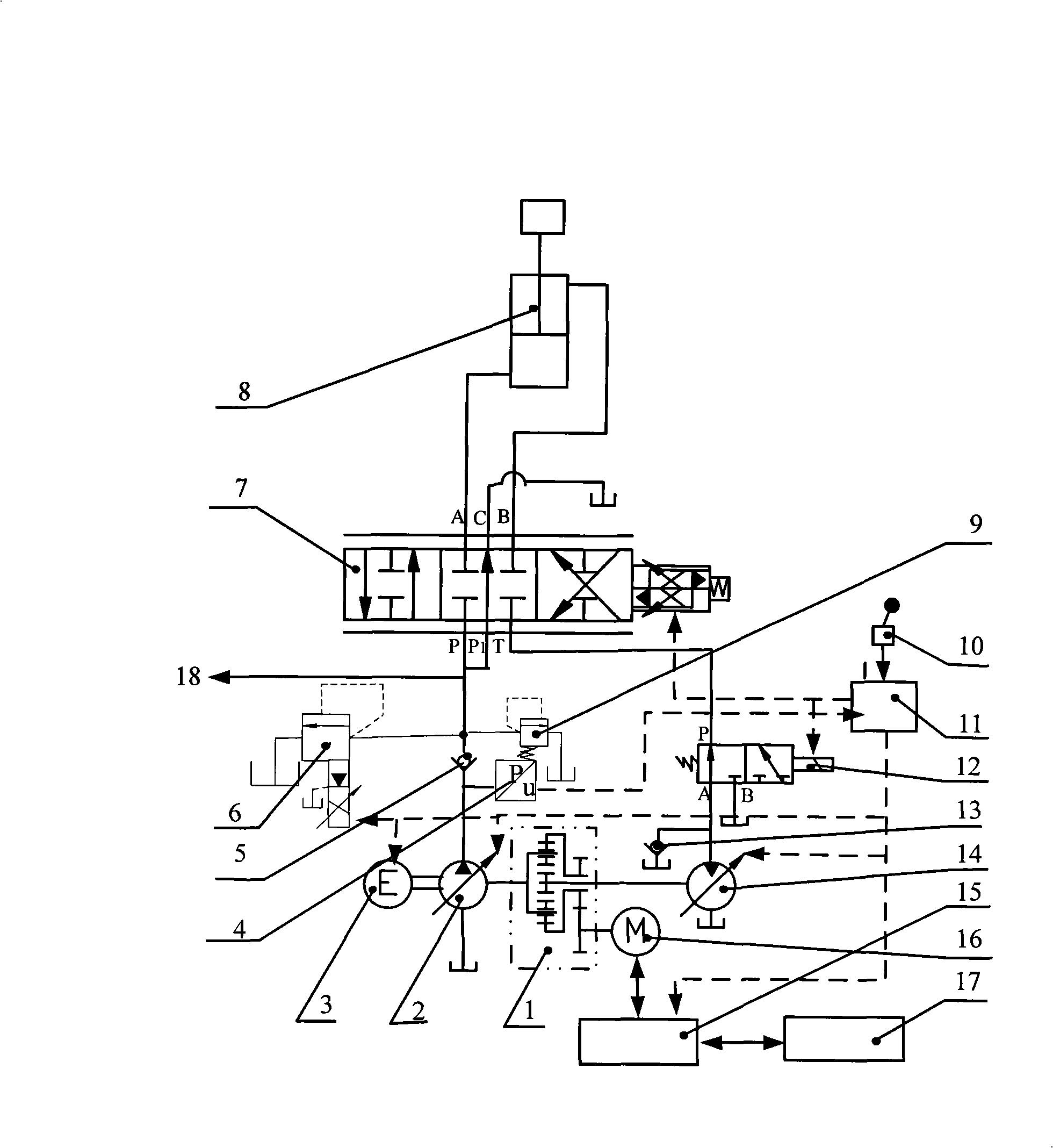

[0015] The details of the present invention are given below through the description of the embodiments in conjunction with the accompanying drawings.

[0016] As shown in the drawings, the present invention includes a planetary gear mechanism 1, a variable displacement pump 2, an engine 3, a proportional directional valve 7, a variable displacement motor 14, two one-way valves 5, 13, a proportional relief valve 6, a safety valve 9, an oil cylinder 8. Control handle 10, pressure sensor 4, signal control unit 11, electromagnetic reversing valve 12, rectifier / inverter 15, variable frequency motor 16 and super capacitor 17; their interconnection relationship is as follows: engine 3, variable displacement pump 2 are coaxial After being connected, it is connected with the planet carrier of the planetary gear mechanism 1; the variable motor 14 is connected with the sun gear of the planetary gear mechanism 1; the variable frequency motor 16 is connected with the ring gear of the planet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com