Production method for spherical iron oxide black magnetic powder used for laser printing, and spherical iron oxide black magnetic powder

A spherical, magnetic powder technology, applied in the preparation method of spherical magnetic powder iron oxide black and the field of spherical iron black magnetic powder, can solve the problem of difficult to obtain stable performance, achieve high blackness, low coercive force, and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

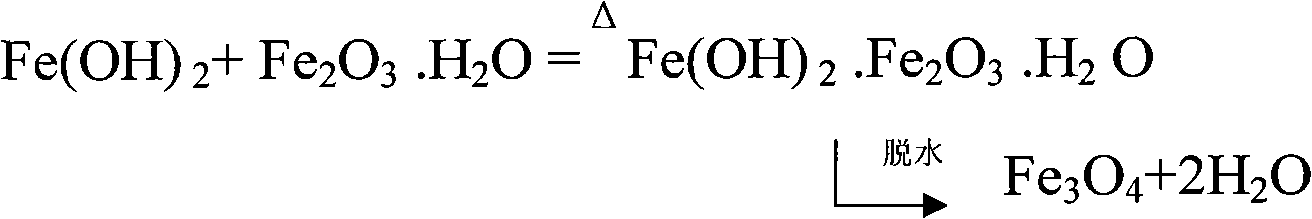

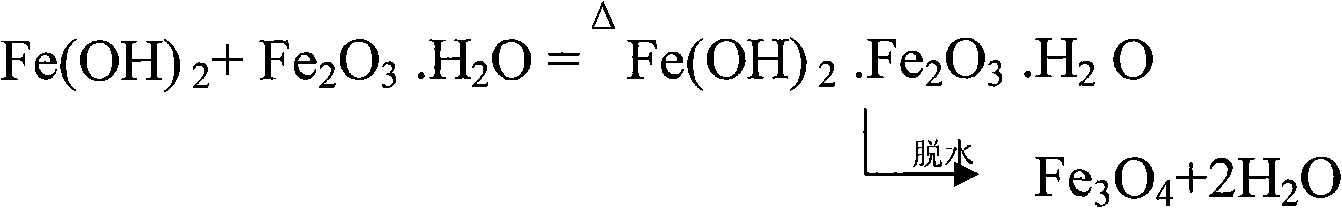

Method used

Image

Examples

Embodiment 1

[0028] In a bucket with a capacity of 30 cubic meters, the ferrous sulfate solution (according to FeSO 4 .7H 2 O counts as 2750 kilograms), adds 650 kilograms of 30% sodium hydroxide solution under stirring at 32 degrees Celsius. Stirring was continued for 5 more minutes after the addition was complete. At this moment, the temperature of the solution is about 35 degrees Celsius. A seed crystal suspension was formed after oxidizing with air for 8 hours. Pump the seed crystal suspension into a 50 cubic meter oxidation barrel filled with iron sheets, dilute with water and oxidize with air at 80 degrees Celsius for 72 hours to obtain iron oxide yellow suspension. This suspension is pumped in the synthetic bucket of 100 cubic meters, adds the ferrous sulfate solution of 35% to make iron yellow: FeSO4.7H 2 O is 1:1.8, and the temperature of the iron yellow suspension is raised to 90-95 degrees Celsius, and slowly add 30% sodium hydroxide solution under stirring to maintain the t...

Embodiment 2

[0037] Different from Example 1 is that in the preparation of iron oxide yellow crystal seed, add 3000 kilograms (with FeSO 4 .7H 2O meter) ferrous sulfate solution and 750 kilograms of 30% sodium hydroxide solution. All the other operations have the following properties with the product that embodiment 1. obtains:

[0038] Fe3O4 content 97.8%

[0039] Hc VSM@10k field 62.29Oe

[0040] Sigma S VSM@10k field 80.02emu / g

[0041] Sigma R VSM@10k field 4.0emu / g

[0042] Spherical particle size 0.20 microns

[0043] The BET specific surface area is 5.9 square meters per gram.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Saturation magnetization | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com