Manganese zinc soft magnetic ferrite and production method for its magnetic core

A manganese-zinc soft magnet and oxygen body technology, which is applied in the fields of inorganic material magnetism, inductance/transformer/magnet manufacturing, electrical components, etc., can solve the problems of no μi temperature curve, large difference in μi, and failure to meet the high-quality requirements of energy-saving lighting, etc. , to achieve the effect of improving ball milling quality, reducing shrinkage, and good material activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

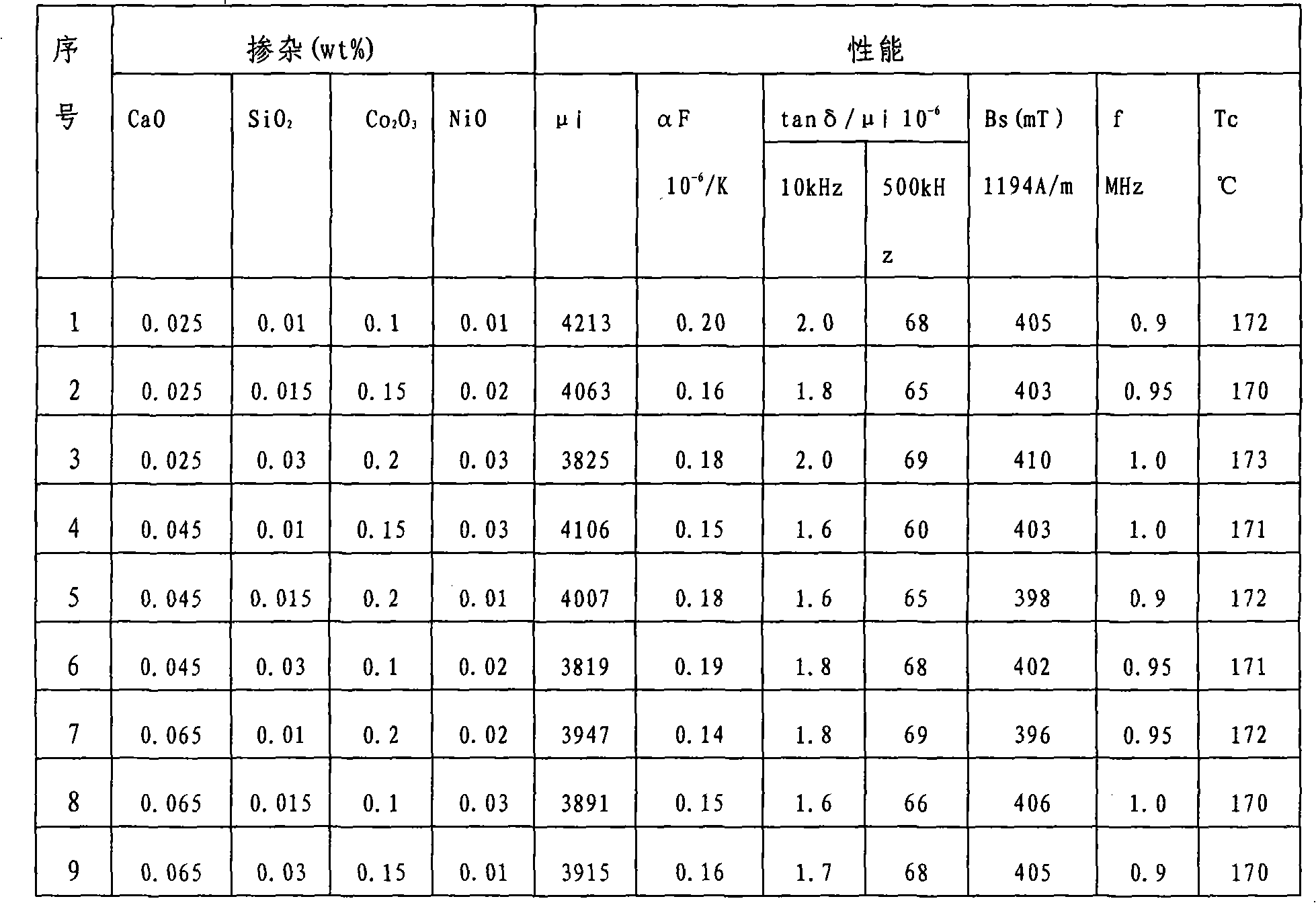

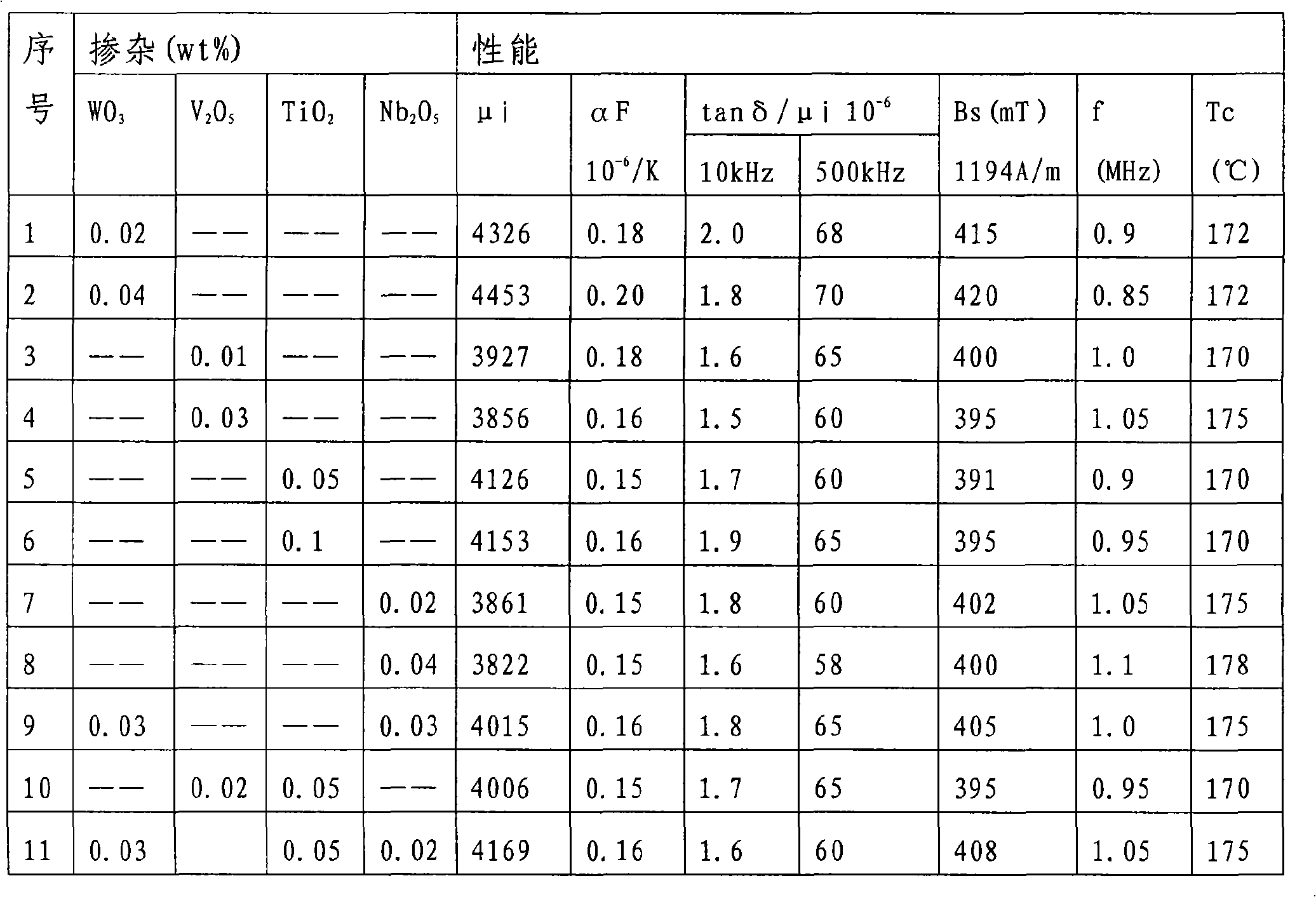

Examples

Embodiment 1

[0013] Accurately weigh 53.15% molFe 2 o 3(purity ≥ 99.3%), 30.2% molMnO, 16.65% mol ZnO (purity ≥ 99.7%) three main raw materials, after a batching and ball milling, spray granulation, pre-calcination, secondary batching and ball milling, pressed into a green body, For the magnetic core obtained in the green body sintering step, 0.2% to 1.5% by weight of a dispersant is added to the primary ingredients. The dispersant is a mixture of water citric acid, acrylic acid, and ammonia water, and its weight ratio is 0.31 to 0.45:0.45 ~0.58: 0.11~0.24 mixing, also add the dispersant that weight percentage is 0.2wt%~1.5wt% in the described primary batching, described dispersant is water citric acid, acrylic acid, ammonia water mixture, its weight ratio 0.31-0.45: 0.45-0.58: 0.11-0.24; a binder is also added to the primary batching, the binder is polyvinyl alcohol, and the weight percentage is 0.6wt%-1.5wt%. Spray granulation to form granules of 80-200 μm, water content of 0.25-0.45%,...

Embodiment 2

[0017] Accurately weigh 52.8% molFe 2 o 3 (purity ≥ 99.3%), 31.9% molMnO, 15.3% mol ZnO (purity ≥ 99.7%) three main raw materials, after a batching and ball milling, spray granulation, pre-calcination, secondary batching and ball milling, pressed into a green body, For the magnetic core obtained in the green body sintering step, 0.2% to 1.5% by weight of a dispersant is added to the primary ingredients. The dispersant is a mixture of water citric acid, acrylic acid, and ammonia water, and its weight ratio is 0.31 to 0.45:0.45 ~0.58: 0.11~0.24 mixing, also add the dispersant that weight percentage is 0.2wt%~1.5wt% in the described primary batching, described dispersant is water citric acid, acrylic acid, ammonia water mixture, its weight ratio 0.31-0.45: 0.45-0.58: 0.11-0.24; a binder is also added to the primary batching, the binder is polyvinyl alcohol, and the weight percentage is 0.6wt%-1.5wt%. Spray granulation to form granules of 80-200 μm, water content of 0.25-0.45%, ...

Embodiment 3

[0021] Accurately weigh 53.5% molFe 2 o 3 (purity ≥ 99.3%), 27.7% molMnO, 18.8% mol ZnO (purity ≥ 99.7%) three main raw materials, after a batching and ball milling, spray granulation, pre-calcination, secondary batching and ball milling, pressed into a green body, For the magnetic core obtained in the green body sintering step, 0.2% to 1.5% by weight of a dispersant is added to the primary ingredients. The dispersant is a mixture of water citric acid, acrylic acid, and ammonia water, and its weight ratio is 0.31 to 0.45:0.45 ~0.58: 0.11~0.24 mixing, also add the dispersant that weight percentage is 0.2wt%~1.5wt% in the described primary batching, described dispersant is water citric acid, acrylic acid, ammonia water mixture, its weight ratio 0.31-0.45: 0.45-0.58: 0.11-0.24; a binder is also added to the primary batching, the binder is polyvinyl alcohol, and the weight percentage is 0.6wt%-1.5wt%. Spray granulation to form granules of 80-200 μm, water content of 0.25-0.45%, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Curie temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com