Dehydration electric motor with aluminum enamel insulated wire stator winding

A wire-covered stator and stator winding technology, which is applied in the field of dehydration motors, can solve the problems of easy damage of embedded wires and difficulties in embedded wires of aluminum enameled wire stator windings, and achieve the effects of preventing corrosion, solving easy damage of embedded wires, and high temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

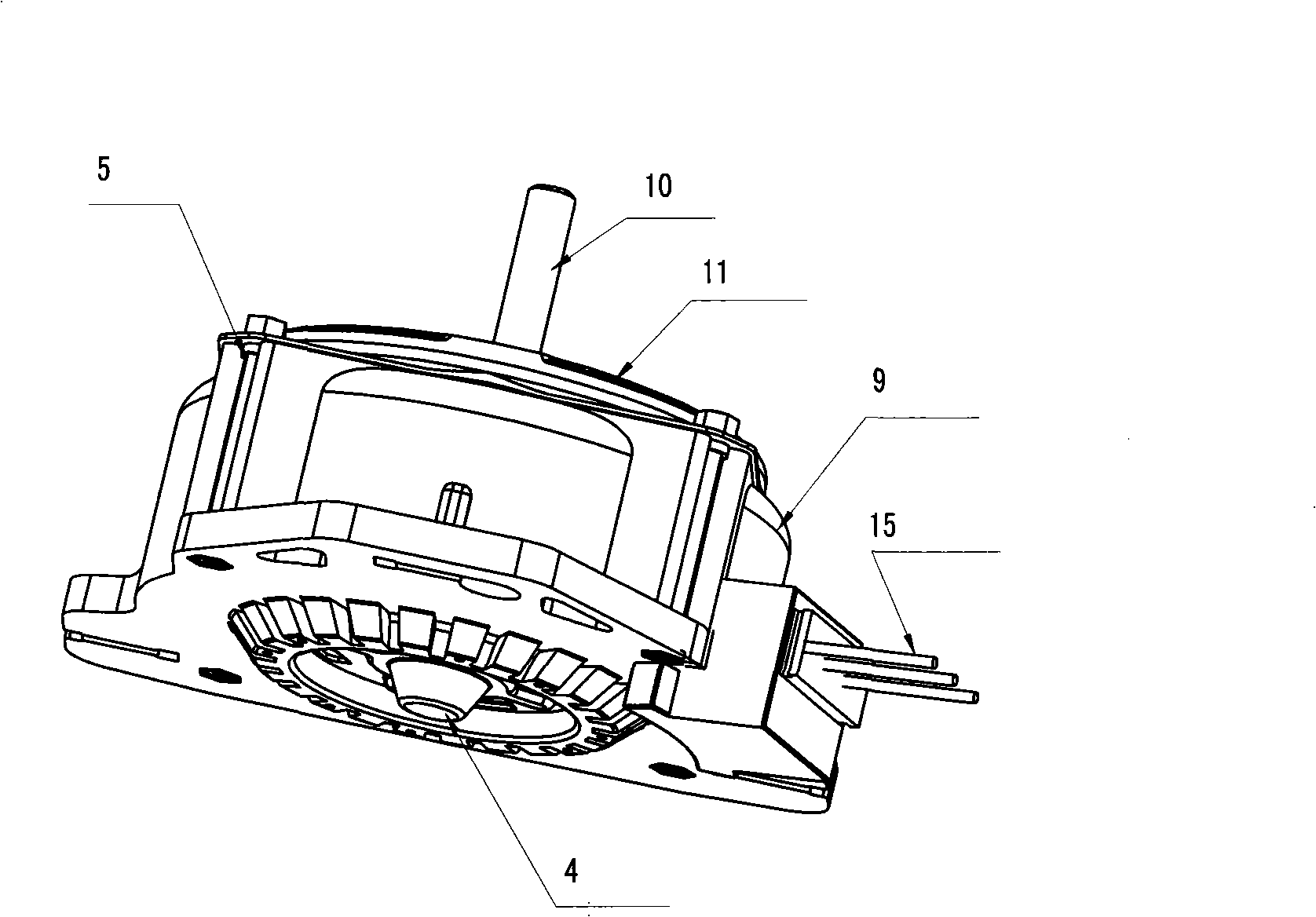

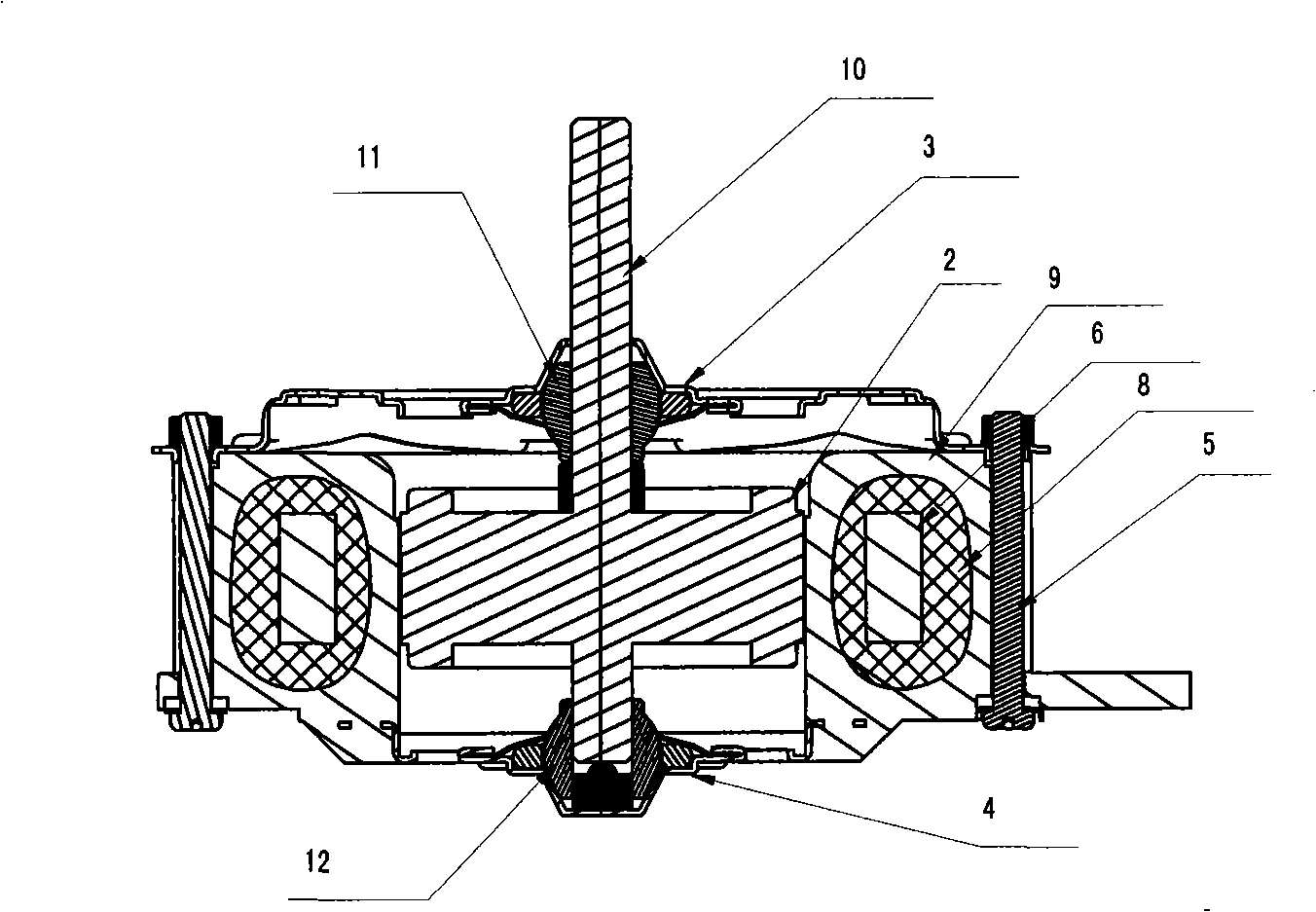

[0037] figure 1 shows the appearance of the motor of the present invention, figure 2 The motor structure of the present invention is shown. Although the motor shown in the drawings is a dewatering motor, the features of the invention are applicable to all motors having stator windings of aluminum enamelled wire.

[0038] Such as figure 1 and figure 2 As shown, the motor with aluminum enameled wire stator windings of the present invention includes a rotor 2, a rotating shaft 10 mounted on the rotor 2, a stator 1 surrounding the rotor 2, wherein the rotating shaft 10 is respectively supported by a front bearing 11 mounted on the front end cover 3 It is supported by the rear bearing 12 installed on the rear end cover 4; the rotor is a squirrel-cage cast aluminum rotor, and the rotating shaft 10 is press-fitted on the rotor core. The front bearing 11 and the rear bearing 12 can be oil-impregnated bearings or ball bearings.

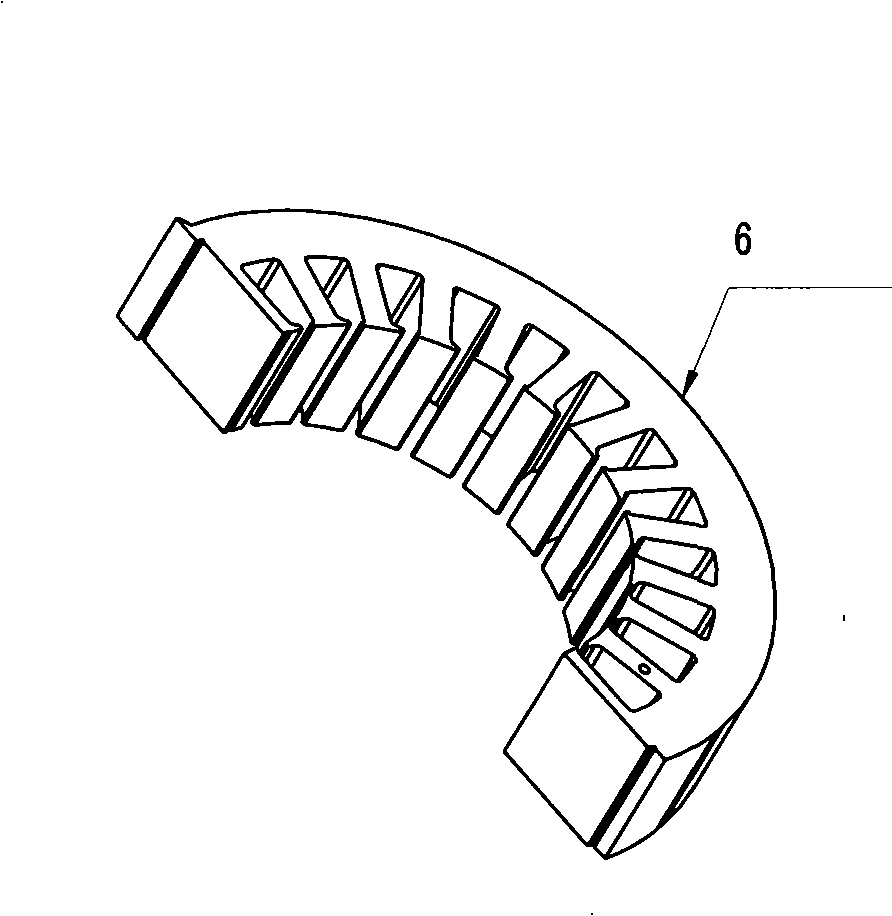

[0039] image 3 shows the structure of the semi-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com